Abstract

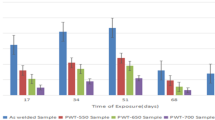

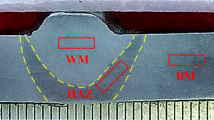

Two welded joints applied for structural steel were exposed in the tropical marine atmospheric environment enduring 12 months in Thailand Trat to evaluate the corrosion resistance. The investigation results disclosed that the difference in microstructure resulted in uneven distribution of hardness and Volta potential in joints. For welds with a high content of Cr and Mn (W2), the hardness and Volta potential values of weld zone (WZ) were higher than those of another weld joint (W1), which was attributed to the addition of Mn and Cr in W2 fill metal. Meanwhile, the values of Ecorr of W2 fill metal were − 0.329 and − 0.601 V for rust and de-rusted conditions, respectively, which were more positive than that of other zones. Electrochemical impedance spectra (EIS) data presented that the corrosion resistance of heat-affected zone (HAZ) in both weld joints were more miserable than other zones in the same joint. In contrast, the inconspicuous corrosion steps between WZ and HAZ indicated a reasonable alloy composition design for both weld joints. The differences in corrosion resistance of subzones indicated that the local galvanic effect is majorly affected by material composition rather than microstructure.

Similar content being viewed by others

References

C. Thee, L. Hao, and J. Dong, Atmospheric Corrosion Monitoring of a Weathering Steel Under an Electrolyte Film in Cyclic Wet–Dry Condition, Corros. Sci., 2014, 78, p 130–137

Y. Ma, Y. Li, and F. Wang, Corrosion of Low Carbon Steel in Atmospheric Environments of Different Chloride Content, Corros. Sci., 2009, 51, p 997–1006

Y.H. Qian, D. Niu, and J.J. Xu, The Influence of Chromium Content on the Electrochemical Behavior of Weathering Steels, Corros. Sci., 2013, 71, p 72–77

D. Kong, C. Dong, X. Ni et al., High-Throughput Fabrication of Nickel-Based Alloys with Different Nb Contents via a Dual-Feed Additive Manufacturing System: Effect of Nb Content on Microstructural and Mechanical Properties, J. Alloy. Compd., 2019, 785, p 826–837

T. Zhang, W. Liu, Z. Yin et al., Effects of the Addition of Cu and Ni on the Corrosion Behavior of Weathering Steels in Corrosive Industrial Environments, J. Mater. Eng. Perform., 2020, 29, p 2531–2541

D. Kong, C. Dong, X. Ni et al., Corrosion of Metallic Materials Fabricated by Selective Laser Melting, Npj Mater. Degrad., 2019, 3(1), p 1–14

Z. Cui, S. Chen, and Y. Dou, Passivation Behavior and Surface Chemistry of 2507 Super Duplex Stainless Steel in Artificial Seawater: Influence of Dissolved Oxygen and pH, Corros. Sci., 2019, 150, p 218–234

G. Song, J. Yu, and T. Li, Effect of Laser-GTAW Hybrid Welding Heat Input on the Performance of Mg/Steel Butt Joint, J. Manuf. Process., 2018, 31, p 131–138

D. Kong, C. Dong, X. Ni et al., Hetero-Deformation Induced Stress in Additively Manufactured 316L Stainless Steel, Mater. Res. Lett., 2020, 11, p 401–408

Y. Zhang, G. Shi, and R. Sun, Effect of Si Content on the Microstructures and the Impact Properties in the Coarse-Grained Heat-Affected Zone (CGHAZ) of Typical Weathering Steel, Mater. Sci. Eng. A, 2019, 762, p 138082

X. Wan, K. Wu, and G. Huang, In Situ Observations of the Formation of Fine-Grained Mixed Microstructures of Acicular Ferrite and Bainite in the Simulated Coarse-Grained Heated-Affected Zone, Steel Res. Int., 2014, 85, p 243–250

B. Hutchinson, J. Komenda, and G.S. Rohrer, Heat Affected Zone Microstructures and Their Influence on Toughness in Two Microalloyed HSLA Steels, Acta Mater., 2015, 97, p 380–391

P. Zhou, B. Wang, L. Wang, Y. Hu, and L. Zhou, Effect of Welding Heat Input on Grain Boundary Evolution and Toughness Properties in CGHAZ of X90 Pipeline Steel, Mater. Sci. Eng. A, 2018, 722, p 112–121

X. Li, B. Gong, X. Liu, C. Deng, and Y. Li, Effects of Hydrogen and Microstructure on Tensile Properties and Failure Mechanism of 304L K-TIG Welded Joint, Mater. Sci. Eng. A, 2018, 735, p 208–217

E. Ranjbarnodeh, S. Serajzadeh, A.H. Kokabi, and A. Fischer, Effect of Welding Parameters on Residual Stresses in Dissimilar Joint of Stainless Steel to Carbon Steel, J. Mater. Sci., 2011, 46, p 3225–3232

W. Hao, Z. Liu, W. Wu, X. Li, C. Du, and D. Zhang, Electrochemical Characterization and Stress Corrosion Cracking of E690 High Strength Steel in Wet–Dry Cyclic Marine Environments, Mater. Sci. Eng. A, 2018, 710, p 318–328

L. Gong, Q. Xing, and H. Wang, Corrosion Behaviors of Weathering Steel 09CuPCrNi Welded Joints in Simulated Marine Atmospheric Environment, Anti-Corros. Methods Mater., 2016, 63(4), p 295–300

W. Wu, Z. Liu, X. Li, C. Du, and Z. Cui, Influence of Different Heat-Affected Zone Microstructures on the Stress Corrosion Behavior and Mechanism of High-Strength Low-Alloy Steel in a Sulfurated Marine Atmosphere, Mater. Sci. Eng. A, 2019, 759, p 124–141

D. Kong, A. Xu, C. Dong et al., Electrochemical Investigation and ab Initio Computation of Passive Film Properties on Copper in Anaerobic Sulphide Solutions, Corros. Sci., 2017, 116, p 34–43

S. Li, X. Yang, F. Wang, W. Tang, and H. Li, Microstructural Characteristics and Mechanical Properties of Friction-Stir-Welded Modified 9Cr1Mo Steel, J. Mater. Sci., 2019, 54, p 6632–6650

N.Z. Gutiérrez, J.V. Alvarado, and H. de Cicco, Microstructural Study of Welded Joints in a High Temperature Martensitic-ferritic ASTM A335 P91 Steel, Procedia Mater. Sci., 2015, 8, p 1140–1149

D. Kong, C. Dong, X. Ni et al., Mechanical Properties and Corrosion Behavior of Selective Laser Melted 316L Stainless Steel After Different Heat Treatment Processes, J. Mater. Sci. Technol., 2019, 35(7), p 1499–1507

S. Lin, Y. Deng, and J.S. Tang, Microstructures and Fatigue Behavior of Metal-Inert-Gbare Welded Joints for Extruded Al-Mg-Si Alloy, Mater. Sci. Eng. A, 2019, 745, p 63–73

T. Zhang, J. Wu, and L. Jin, Enhancing the Mechanical and Anticorrosion Properties of 316L Stainless Steel via a Cathodic Plasma Electrolytic Nitriding Treatment with Added PEG, J. Mater. Sci. Technol., 2019, 35(11), p 2630–2637

D. Kong, X. Ni, C. Dong et al., Bio-functional and Anti-Corrosive 3D Printing 316L Stainless Steel Fabricated by Selective Laser Melting, Mater. Des., 2018, 152, p 88–101

C. Pandey, M.M. Mahapatra, and P. Kumar, Some Studies on P91 Steel and Their Weldments, J. Alloy. Compd., 2018, 743, p 332–364

W. Zhang, G. Zhao, and Q. Fu, Study on the Effects and Mechanisms of Induction Heat Treatment Cycles on Toughness of High Frequency Welded Pipe Welds, Mater. Sci. Eng. A, 2018, 736, p 276–287

D. Kong, C. Dong, X. Ni et al., The Passivity of Selective Laser Melted 316L Stainless Steel, Appl. Surf. Sci., 2020, 504, p 144495

C. Pandey, M. Mohan Mahapatra, P. Kumar, and J.G. Thakre, Role of Evolving Microstructure on the Mechanical Behaviour of P92 Steel Welded Joint in Bare Welded and Post Weld Heat Treated State, J. Mater. Process. Technol., 2019, 263, p 241–255

S. Ghorbani, R. Ghasemi, and R. Ebrahimi-Kahrizsangi, Effect of Post Weld Heat Treatment (PWHT) on the Microstructure, Mechanical Properties, and Corrosion Resistance of Dissimilar Stainless Steels, Mater. Sci. Eng. A, 2017, 688, p 470–479

D. Kong, C. Dong, X. Ni et al., Superior Resistance to Hydrogen Damage for Selective Laser Melted 316L Stainless Steel in a Proton Exchange Membrane Fuel Cell Environment, Corros. Sci., 2020, 166(15), p 108–119

H. Chen, H. Feng, and H.X. Liu, The Galvanic Effect of High-Strength Weathering Steel Welded Joints and its Influence on Corrosion Resistance, Corros. Eng. Sci. Technol., 2019, 54, p 556–566

C. Pandey, M.M. Mahapatra, and P. Kumar, Microstructure and Mechanical Property Relationship for Different Heat Treatment and Hydrogen Level in Multi-Pass Welded P91 Steel Joint, J. Manuf. Process, 2017, 28, p 220–234

D. Kong, X. Ni, C. Dong et al., Heat Treatment Effect on the Microstructure and Corrosion Behavior of 316L Stainless Steel Fabricated by Selective Laser Melting for Proton Exchange Membrane Fuel Cells, Electrochim. Acta, 2018, 276, p 293–303

D. Kong, X. Ni, C. Dong et al., Anisotropy in the Microstructure and Mechanical Property for the Bulk and Porous 316L Stainless Steel Fabricated via Selective Laser Melting, Mater. Lett., 2019, 235, p 1–5

A.V. Latifi, R. Miresmaeili, and A. Abdollah-Zadeh, The Mutual Effects of Hydrogen and Microstructure on Hardness and Impact Energy of SMA Welds in X65 steel, Mater. Sci. Eng. A, 2017, 679, p 87–94

C. Dai, H. Luo, and J. Li, X-ray Photoelectron Spectroscopy and Electrochemical Investigation of the Passive Behavior of High-Entropy FeCoCrNiMox Alloys in Sulfuric Acid, Appl. Surf. Sci., 2020, 499, p 143903

Acknowledgments

The authors acknowledge the support from the National Key R&D Program of China (2016YFE0203600) and the National Natural Science Foundation of China (51571027).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, T., Liu, W., Chowwanonthapunya, T. et al. Corrosion Evolution and Analysis of Welded Joints of Structural Steel Performed in a Tropical Marine Atmospheric Environment. J. of Materi Eng and Perform 29, 5057–5068 (2020). https://doi.org/10.1007/s11665-020-05045-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05045-9