Abstract

Due to the non-uniform dynamic recrystallization (DRX) and deformation behavior during hot forging process, the spur bevel gears tend to receive heterogeneous microstructure which greatly affects their mechanical properties and service life. Therefore, the aim of this study is to investigate the evolution of microstructure and texture of hot forged 20CrMnTiH steel spur bevel gear utilizing both simulation and experiment method. In the present study, a sound finite element model of hot forging of a 20CrMnTiH steel spur bevel gear was developed under the Deform-3D software. The experimental analysis was conducted by employing scanning electron microscope, electron backscatter diffraction and transmission electron microscope. The simulation results indicated that the grain size, effective strain and DRX volume fraction were inhomogeneous from the surface region to the core region of gear tooth. The experimental analysis revealed that the surface region of gear tooth possessed the strongest γ-fiber and lowest dislocation density. However, both subsurface and core regions had a combination of moderate α- and γ-fibers, and large amount of dislocations pinned by precipitates can be observed in these two regions. Furthermore, the microhardness exhibited parabola distribution through the gear tooth, and the subsurface region possessed the largest microhardness value.

Similar content being viewed by others

References

J.R. Cho, W.J. Kang, M.G. Kim, J.H. Lee, Y.S. Lee, and W.B. Bae, Distortions Induced by Heat Treatment of Automotive Bevel Gears, J. Mater. Process. Technol., 2004, 153–154, p 476–481

M. Irani and A.K. Taheri, Effect of Forging Temperature on Homogeneity of Microstructure and Hardness of Precision Forged Steel Spur Gear, Mater. Chem. Phys., 2008, 112, p 1099–1105

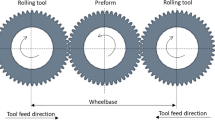

X. Deng, L. Hua, X. Han, and Y. Song, Numerical and Experimental Investigation of Cold Rotary Forging of a 20CrMnTi Alloy Spur Bevel Gear, Mater. Des., 2011, 32, p 1376–1389

Z.Y. Jin, N.N. Li, Q. Zhang, K. Yan, and Z.S. Cui, Effects of Forging Parameters on Uniformity in Deformation and Microstructure of AZ31B Straight Spur Gear, Trans. Nonferr. Met. Soc. China, 2017, 27, p 2172–2180

Y.S. Jang, D.C. Ko, and B.M. Kim, Application of the Finite Element Method to Predict Microstructure Evolution in the Hot Forging of Steel, J. Mater. Process. Technol., 2000, 101, p 85–94

H.S. Zurob, C.R. Hutchinson, Y. Brechet, and G. Purdy, Modeling Recrystallization of Microalloyed Austenite: Effect of Coupling Recovery, Precipitation and Recrystallization, Acta Mater., 2000, 50, p 3075–3092

R.S. Nalawade, A.J. Puranik, G. Balachandran, K.N. Mahadik, and V. Balasubramanian, Simulation of Hot Rolling Deformation at Intermediate Passes and Its Industrial Validity, Int. J. Mech. Sci., 2013, 77, p 8–16

W. Wang, H. Liu, C. Zhu, P. Wei, and J. Tang, Effects of Microstructure on Rolling Contact Fatigue of a Wind Turbine Gear Based on Crystal Plasticity Modeling, Int. J. Fatigue, 2019, 120, p 73–86

Y. Guo, Y. Cao, M. Sun, B. Xu, and D. Li, Effects of Liquid Fraction on the Microstructure and Mechanical Properties in Forge Solidifying 12Cr1MoV Steel, J. Mater. Process. Technol., 2018, 256, p 25–35

Y.C. Lin, M.S. Chen, and J. Zhong, Microstructural Evolution in 42CrMo Steel during Compression at Elevated Temperatures, Mater. Lett., 2008, 62, p 2132–2135

A. Lanzutti, M. Pujatti, M. Magnan, F. Andreatta, H. Nurmi, A. Silvonen, E. Hlede, and L. Fedrizzi, Uniaxial Fatigue Properties of Closed Die Hot Forged 42CrMo4 Steel: Effect of Flash and Mechanical Surface Treatments, Mater. Des., 2017, 132, p 324–336

N.T. Switzner, E.T. Sawyer, W.A. Everhart, and R.L. Hanlin, Predicting Microstructure and Strength for AISI, 304L Stainless Steel Forgings, Mater. Sci. Eng. A, 2019, 745, p 474–483

S.T. Wu, W. Feng, and X. Hu, Constitutive Modelling of Flow Behaviour of 20CrMnTiH Steel, Ironmak. Steelmak., 2015, 42, p 481–488

F. Wei and W. Shuting, Effect of Deformation Temperature on Microstructure Evolution for 20CrMnTiH Steel during Hot Compression, Adv. Mater. Res., 2015, 1095, p 727–731

Y.C. Lin and M.S. Chen, Numerical Simulation and Experimental Verification of Microstructure Evolution in a Three-Dimensional Hot Upsetting Process, J. Mater. Process. Technol., 2009, 209, p 4578–4583

M.S. Ghazani and B. Eghbali, Prediction of Post-deformation Recrystallization Kinetics in AISI, 321 Austenitic Stainless Steel Using Double-Stage Hot Compression, J. Mater. Eng. Perform., 2019, 28, p 3567–3575

T. Henke, M. Bambach, and G. Hirt, Quantification of Uncertainties in Grain Size Predictions of a Microstructure-Based Flow Stress Model and Application to Gear Wheel Forging, CIRP Ann. Manuf. Technol., 2013, 62, p 287–290

S. Wang, B. Yang, M. Zhang, H. Wua, J. Peng, and Y. Gao, Numerical Simulation and Experimental Verification of Microstructure Evolution in Large Forged Pipe Used for AP1000 Nuclear Power Plants, Ann. Nucl. Energy, 2016, 87, p 176–185

A. Łukaszek-Sołek, J. Krawczyk, T. Śleboda, and J. Grelowski, Optimization of the Hot Forging Parameters for 4340 Steel by Processing Maps, J. Mater. Res. Technol., 2019, 3, p 3281–3290

N. Zhang, P. Yang, and W. Mao, {001}<120>−{113}<361> Recrystallization Textures Induced by Initial {001 Grains and Related Microstructure Evolution in Heavily Rolled Electrical Steel, Mater. Charact., 2016, 119, p 225–232

I. Samajdar, B. Verlinden, P.V. Houtte, and D. Vanderschueren, γ-Fibre Recrystallization Texture in IF-Steel: An Investigation on the Recrystallization Mechanisms, Mater. Sci. Eng. A, 1997, 238, p 343–350

M.E. Wahabi, L. Gavard, J.M. Cabrera, J.M. Prado, and F. Montheillet, EBSD Study of Purity Effects during Hot Working in Austenitic Stainless Steels, Mater. Sci. Eng. A, 2005, 393, p 83–90

J. Wang and S.C. Zhai, Dynamic Recrystallization Kinetics of 690 Alloy during Hot Compression of Double-Cone Samples, J. Mater. Eng. Perform., 2017, 26, p 1433–1443

D. Liu, H. Ding, M. Cai, and D. Han, Hot Deformation Behavior and Processing Map of a Fe-11Mn-10Al-0.9C Duplex Low-Density Steel Susceptible to κ-Carbides, J. Mater. Eng. Perform., 2019, 28, p 5116–5126

S.P. Coryell, K.O. Findley, M.C. Mataya, and E. Brown, Evolution of Microstructure and Texture during Hot Compression of a Ni-Fe-Cr Superalloy, Metall. Mater. Trans. A, 2012, 43, p 633–649

T. Sakai, A. Belyakov, R. Kaibyshev, H. Miura, and J.J. Jonas, Dynamic and Post-dynamic Recrystallization under Hot, Cold and Severe Plastic Deformation Conditions, Prog. Mater Sci., 2014, 60, p 130–207

Y. Hayakawa and J.A. Szpunar, A New Model of Goss Texture Development during Secondary Recrystallization of Electrical Steel, Acta Mater., 1997, 45, p 4713–4720

J.T. Park and J.A. Szpunar, Evolution of Recrystallization Texture in Nonoriented Electrical Steels, Acta Mater., 2003, 51, p 3037–3051

C. Yue, L. Zhang, S. Liao, and H. Gao, Kinetic Analysis of the Austenite Grain Growth in GCr15 Steel, J. Mater. Eng. Perform., 2010, 19, p 112–115

F. Yin, L. Hua, H. Mao, X. Han, D. Qian, and R. Zhang, Microstructural Modeling and Simulation for GCr15 Steel during Elevated Temperature Deformation, Mater. Des., 2014, 55, p 560–573

M. Zhou and M.P. Clode, Constitutive Equations for Modelling Flow Softening Due to Dynamic Recovery and Heat Generation during Plastic Deformation, Mech. Mater., 1998, 27, p 63–76

Y.C. Lin, M.S. Chen, and J. Zhong, Numerical Simulation for Stress/Strain Distribution and Microstructural Evolution in 42CrMo Steel during Hot Upsetting Process, Comput. Mater. Sci., 2008, 4, p 1117–1122

L. Qing, H. Xiaoxu, Y. Mei, and Y. Jinfeng, On Deformation-Induced Conditions Recrystallization in a Superplastic Al-Li-Cu-Mg-Zr Alloy, Acta Metall. Mater., 1992, 40, p 1753–1762

X. Han, L. Dong, L. Hua, and W. Zhuang, Microstructure and Texture Evolution in Cold Rotary Forging of Spur Bevel Gears of 20CrMnTi Alloy Steel, J. Mater. Eng. Perform., 2016, 25, p 1182–1190

J. Copreaux, S. Lanteri, and J.-H. Schmitt, Effect of Precipitation on the Development of Dislocation Substructure in Low Carbon Steels during Cold Deformation, Mater. Sci. Eng. A, 1993, 164, p 201–205

S. Gourdet and F. Montheillet, A Model of Continuous Dynamic Recrystallization, Acta Mater., 2003, 51, p 2685–2699

H. Mirzadeh, J.M. Cabrera, A. Najafizadeh, and P.R. Calvillo, EBSD Study of a Hot Deformed Austenitic Stainless Steel, Mater. Sci. Eng. A, 2012, 538, p 236–245

S. Diligent, E. Gautier, X. Lemoine, and M. Berveiller, Lattice Orientation Dependence of the Stored Energy during Cold-Rolling of Polycrystalline Steels, Acta Mater., 2001, 49, p 4079–4088

Y.H. Guo, Z.D. Wang, and L.Q. Wei, Investigation on the Recrystallization Mechanism in Warm-Rolled Ti-IF Steel, J. Mater. Eng. Perform., 2014, 23, p 1214–1222

Y. Feng, Y. Li, J. Guo, J. Li, and T. Du, Effect of Slab Reheating Temperature on Recrystallization Microstructure, Texture and Magnetic Properties of Nb-Containing Grain-Oriented Silicon Steel, J. Magn. Magn. Mater., 2017, 439, p 135–143

W. Wei, K.X. Wei, and G.J. Fan, A New Constitutive Equation for Strain Hardening and Softening of fcc Metals during Severe Plastic Deformation, Acta Mater., 2008, 56, p 4771–4779

P.A. Beaven and E.P. Butler, Precipitate Nucleation on Dislocations in Fe-N, Acta Metall., 1980, 28, p 1349–1359

L. Zhou, G. Liu, X.L. Ma, and K. Lu, Strain-Induced Refinement in a Steel with Spheroidal Cementite Subjected to Surface Mechanical Attrition Treatment, Acta Mater., 2008, 56, p 78–87

Z.L. Hu, S.J. Yuan, X.S. Wang, G. Liu, and H.J. Liu, Microstructure and Mechanical Properties of Al-Cu-Mg Alloy Tube Fabricated by Friction Stir Welding and Tube Spinning, Scr. Mater., 2012, 66, p 427–430

C. Roucoules, M. Pietrzyk, and P.D. Hodgson, Analysis of Work Hardening and Recrystallization during the Hot Working of Steel Using a Statistically Based Internal Variable Model, Mater. Sci. Eng. A, 2003, 339, p 1–9

Acknowledgments

The authors would like to thank the National Natural Science Foundation of China (No. 51575416), 111 Project (B17034), Innovative Research Team Development Program of Ministry of Education of China (No. IRT_17R83), Science and Technology Support Program of Hubei Province (No. 2015BAA039) and Wuhan Youth Science and Technology Plan (No. 2016070204010126) for the support given to this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hu, X., Hua, L. & Han, X. Study on the Microstructure and Texture Evolution of Hot Forged 20CrMnTiH Steel Spur Bevel Gear by Simulation and Experiment. J. of Materi Eng and Perform 29, 3688–3701 (2020). https://doi.org/10.1007/s11665-020-04839-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04839-1