Abstract

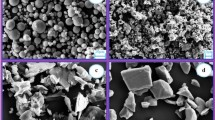

Composite strips based on an Al-Li-Cu-Mg-Zr alloy reinforced with titanium–carbide (TiC) microparticles were manufactured through the accumulative roll bonding (ARB) process. The microstructure, mechanical and thermal conductivity properties of the processed composites have been experimentally investigated and compared with the as-hot-rolled and un-reinforced states. The microstructure of the reinforced sheets shows the excellent reinforcement’s dispersion after the second ARB cycle. In addition, the obtained results indicate that the overall properties of the ARBed strips are enhanced by increasing the TiC content up to 2 wt.%. The processed sheets reinforced with 2 wt.% TiC after two ARB cycles present the superior comprehensive combination of the grain refining, good bonding and proper particle dispersions to reach the outstanding tensile, bending and specific strengths, appropriate tensile elongation and thermal conductivity. Herein, the tensile and bending strengths reach 380.79 and 623.69 MPa, respectively, which are considerably higher than 260.14 and 438.35 MPa, 322.34 and 528.67 MPa of the as-hot-rolled and the un-reinforced sheets after the same cycle, respectively. Moreover, the fracture morphologies of the processed strips exhibit a ductile-shear mixed fracture responding to good elongations of the specimens.

Similar content being viewed by others

References

J. Moradgholi, A. Monshi, K. Farmanesh, M.R. Toroghinejad, and M.R. Loghman-Estarki, Comparison of Microstructure, Toughness, Mechanical Properties and Work Hardening of Titanium/TiO2 and Titanium/SiC Composites Manufactured by Accumulative Roll Bonding (ARB) Process, Ceram. Int., 2017, 43(10), p 7701–7709

E. Ahmadi, M. Ranjkesh, E. Mansoori, M. Fattahi, R.Y. Mojallal, and S. Amirkhanlou, Microstructure and Mechanical Properties of Al/ZrC/TiC Hybrid Nanocomposite Filler Metals of Tungsten Inert Gas Welding Fabricated by Accumulative Roll Bonding, J. Manuf. Process., 2017, 26, p 173–177

W. Zheng, Y.X. Gao, X.P. Wang, H. Lu, L.F. Zeng, and Q.F. Fang, High Strength and Damping Capacity of LLZNO/Al Composites Fabricated by Accumulative Roll Bonding, Mater. Sci. Eng. A, 2017, 689, p 306–312

S. Scudino, G. Liu, K.G. Prashanth, B. Bartusch, and K.B. Surreddi, Mechanical Properties of Al-Based Metal Matrix Composites Reinforced with Zr-based Glassy Particles Produced by Powder Metallurgy, Acta Mater., 2009, 57, p 2029–2039

M. Rahimian, N. Parvin, and N. Ehsani, Investigation of Particle Size and Amount of Alumina on Microstructure and Mechanical Properties of Al Matrix Composite Made by Powder Metallurgy, Mater. Sci. Eng. A, 2010, 527(4–5), p 1031–1038

D.B. Miracle and S.L. Donaldson, Composites, ASM International, Cleveland, 2001

K. Sukumaran, K.K. Ravikumar, S.G.K. Pillai, T.P.D. Rajan, M. Ravi, R.M. Pillai, and B.C. Pai, Studies on Squeeze Casting of Al 2124 Alloy and 2124-10% SiCp Metal Matrix Composite, Mater. Sci. Eng. A, 2008, 490(1–2), p 235–241

S.-N. Chou, J.-L. Huang, D.-F. Lii, and H.-H. Lu, The Mechanical Properties of Al2O3/Aluminum Alloy A356 Composite Manufactured by Squeeze Casting, J. Alloys Compd, 2006, 419(1–2), p 98–102

C. Lu, K. Tieu, and D. Wexler, Significant Enhancement of Bond Strength in the Accumulative Roll Bonding Process Using Nano-sized SiO2 Particles, J. Mater. Process. Technol., 2009, 209(10), p 4830–4834

M. Alizadeh and M.H. Paydar, Fabrication of Nanostructure Al/SiCP Composite by Accumulative Roll-Bonding (ARB) Process, J. Alloys Compd., 2010, 492(1–2), p 231–235

J. Nie, F. Wang, Y. Li, Y. Cao, X. Liu, Y. Zhao, and Y. Zhu, Microstructure evolution and Mechanical Properties of Al-TiB2/TiC In Situ Aluminum-Based Composites during Accumulative Roll Bonding (ARB) Process, Materials, 2017, 10(2), p 109–121

A. Fathy, D. Ibrahim, O. Elkady, and M. Hassan, Evaluation of Mechanical Properties of 1050-Al Reinforced with SiC Particles via Accumulative Roll Bonding Process, J. Compos. Mater., 2018, 53(2), p 209–218

M. Reihanian, S. Fayezipour, and S.M. Lari Baghal, Nanostructured Al/SiC-Graphite Composites Produced by Accumulative Roll Bonding: Role of Graphite on Microstructure, Wear and Tensile Behavior, J. Mater. Eng. Perform., 2017, 26(4), p 1908–1919

M.R. Morovvati and B. Mollaei-Dariani, The Formability Investigation of CNT-Reinforced Aluminum Nano-composite Sheets Manufactured by Accumulative Roll Bonding, Int. J. Adv. Manuf. Technol., 2018, 95(9–12), p 3523–3533

P. Farhadipour, M. Sedighi, and M. Heydari Vini, Influence of Temperature of Accumulative Roll Bonding on the Mechanical Properties of AA5083–1% Al2O3 Composite, Powder Metall. Met. Ceram., 2018, 56(9–10), p 496–503

M. Abbasi and S.A. Sajjadi, Manufacturing of Al–Al2O3–Mg Multilayered Nanocomposites by Accumulative Roll Bonding Process and Study of Its Microstructure, Tensile, and Bending Properties, J. Compos. Mater., 2017, 52(2), p 147–157

M. Naseri, A. Hassani, and M. Tajally, An alternative Method for Manufacturing Al/B4C/SiC Hybrid Composite Strips by Cross Accumulative Roll Bonding (CARB) Process, Ceram. Int., 2015, 41(10), p 13461–13469

C.Y. Liu, Q. Wang, Y.Z. Jia, B. Zhang, R. Jing, M.Z. Ma, Q. Jing, and R.P. Liu, Evaluation of Mechanical Properties of 1060-Al Reinforced with WC Particles via Warm Accumulative Roll Bonding Process, Mater. Des., 2013, 43, p 367–372

P. Farhadipour, M. Sedighi, and M.H. Vini, Using Warm Accumulative Roll Bonding Method to Produce Al-Al2O3 Metal Matrix Composite, Proc. Inst. Mech. Eng. Part B J. Eng. Manuf., 2017, 231(5), p 889–896

R. Jamaati and M.R. Toroghinejad, Application of ARB Process for Manufacturing High-Strength, Finely Dispersed and Highly Uniform Cu/Al2O3 Composite, Mater. Sci. Eng. A, 2010, 527(27–28), p 7430–7435

M. Rezayat, A. Akbarzadeh, and A. Owhadi, Fabrication of High-Strength Al/SiCp Nanocomposite Sheets by Accumulative Roll Bonding, Metall. Mater. Trans. A, 2012, 43(6), p 2085–2093

L. Hou, T. Wang, R. Wu, J. Zhang, M. Zhang, A. Dong, B. Sun, S. Betsofen, and B. Krit, Microstructure and Mechanical Properties of Mg-5Li-1Al Sheets Prepared by Accumulative Roll Bonding, J. Mater. Sci. Technol., 2018, 34(2), p 317–323

A. Medjahed, B. Li, L. Hou, R. Wu, A. Zegaoui, M. Derradji, and H. Benyamina, Evolution of Microstructure, Mechanical Properties, and Thermal Conductivity of an Al-Li-Cu-Mg-Zr Alloy Processed by Accumulative Roll Bonding (ARB), JOM, 2019, https://doi.org/10.1007/s11837-019-03646-x

T. Yu, B. Li, A. Medjahed, L. Hou, R. Wu, J. Zhang, and J. Sun, Impeding Effect of the Al3(Er, Zr, Li) Particles on Planar Slip and Intergranular Fracture Mechanism of Al-3Li-1Cu-0.1Zr-X Alloys, Mater. Charact., 2019, 147, p 146–154

A. Medjahed, H. Moula, A. Zegaoui, M. Derradji, A. Henniche, R. Wu, L. Hou, J. Zhang, and M. Zhang, Influence of the Rolling Direction on the Microstructure, Mechanical, Anisotropy and Gamma Rays Shielding Properties of an Al-Cu-Li-Mg-X Alloy, Mater. Sci. Eng. A, 2018, 732, p 129–137

A. Medjahed, A. Henniche, M. Derradji, T. Yu, Y. Wang, R. Wu, L. Hou, J. Zhang, X. Li, and M. Zhang, Effects of Cu/Mg Ratio on the Microstructure, Mechanical and Corrosion Properties of Al-Li-Cu-Mg-X Alloys, Mater. Sci. Eng. A, 2018, 718, p 241–249

A. Zegaoui, M. Derradji, R. Ma, W. Cai, A. Medjahed, W. Liu, A. Qadeer Dayo, and J. Wang, Silane-Modified Carbon Fibers Reinforced Cyanate Ester/Benzoxazine Resin Composites: Morphological, Mechanical and Thermal Degradation Properties, Vacuum, 2018, 150, p 12–23

A. Zegaoui, M. Derradji, R.-K. Ma, W.-A. Cai, A. Medjahed, W.-B. Liu, A.Q. Dayo, J. Wang, and G.-X. Wang, Influence of Fiber Volume Fractions on the Performances of Alkali Modified Hemp Fibers Reinforced Cyanate Ester/Benzoxazine Blend Composites, Mater. Chem. Phys., 2018, 213, p 146–156

A. Medjahed, M. Derradji, A. Zegaoui, R. Wu, and B. Li, Mechanical and Gamma Rays Shielding Properties of a Novel Fiber-Metal Laminate Based on a Basalt/Phthalonitrile Composite and an Al-Li Alloy, Compos. Struct., 2019, 210, p 421–429

A. Medjahed, M. Derradji, A. Zegaoui, R. Wu, B. Li, Y. Wang, L. Hou, J. Zhang, and M. Zhang, Fabrication Process, Tensile, and Gamma Rays Shielding Properties of Newly Developed Fiber Metal Laminates Based on an Al-Li Alloy and Carbon FibersTungsten Carbide Nanoparticles Reinforced Phthalonitrile Resin Composite, Adv. Eng. Mater., 2018, 21(2), p 1800779

M. Sedighi, M.H. Vini, and P. Farhadipour, Effect of Alumina Content on the Mechanical Properties of AA5083/Al2O3 Composites Fabricated by Warm Accumulative Roll Bonding, Powder Metall. Met. Ceram., 2016, 55(7–8), p 413–418

C.Y. Liu, Q. Wang, Y.Z. Jia, B. Zhang, R. Jing, M.Z. Ma, Q. Jing, and R.P. Liu, Effect of W Particles on the Properties of Accumulatively Roll-Bonded Al/W Composites, Mater. Sci. Eng. A, 2012, 547, p 120–124

M. Alizadeh, Effects of Temperature and B4C Content on the Bonding Properties of Roll-Bonded Aluminum Strips, J. Mater. Sci., 2012, 47(11), p 4689–4695

Y.-C. Kang and S.L.-I. Chan, Tensile Properties of Nanometric Al2O3 Particulate-Reinforced Aluminum Matrix Composites, Mater. Chem. Phys., 2004, 85(2–3), p 438–443

J. Cabrero, F. Audubert, and R. Pailler, Fabrication and Characterization of Sintered TiC–SiC Composites, J. Eur. Ceram. Soc., 2011, 31(3), p 313–320

C.W. Schmidt, C. Knieke, V. Maier, H.W. Höppel, W. Peukert, and M. Göken, Accelerated Grain Refinement during Accumulative Roll Bonding by Nanoparticle Reinforcement, Scr. Mater., 2011, 64(3), p 245–248

H. Akbari Beni, M. Alizadeh, M. Ghaffari, and R. Amini, Investigation of grain refinement in Al/Al2O3/B4C nano-composite produced by ARB, Compos. Part B Eng., 2014, 58, p 438–442

R. Jamaati and M.R. Toroghinejad, High-Strength and Highly-Uniform Composite Produced by Anodizing and Accumulative Roll Bonding Processes, Mater. Des., 2010, 31(10), p 4816–4822

S. Khoramkhorshid, M. Alizadeh, A.H. Taghvaei, and S. Scudino, Microstructure and Mechanical Properties of Al-Based Metal Matrix Composites Reinforced with Al84Gd6Ni7Co3 Glassy Particles Produced by Accumulative Roll Bonding, Mater. Des., 2016, 90, p 137–144

S.S. Reihani, Processing of Squeeze Cast Al6061–30vol% SiC Composites and Their Characterization, Mater. Des., 2006, 27(3), p 216–222

S.H. Dhoria, V.D. Rao, and K.V. Subbaiah, Mechanical and Wear Behaviour of 6351 Al/Gr/SiC Composites Fabricated by Squeeze Casting, Mater. Today Proc., 2019, 1(18), p 2107–2113

C.H. Fan, O.U. Ling, Z.Y. Hu, J.J. Yang, C.H. Gang, and H.G. Yan, Microstructures and Mechanical Properties of BP/7A04 Al Matrix Composites, Trans. Nonferr. Met. Soc. China, 2019, 29(10), p 2027–2034

Z. Wang, K.G. Prashanth, S. Scudino, A.K. Chaubey, D.J. Sordelet, W.W. Zhang, Y.Y. Li, and J. Eckert, Tensile Properties of Al Matrix Composites Reinforced with In Situ Devitrified Al84Gd6Ni7Co3 Glassy Particles, J. Alloys Compd., 2014, 586, p S419–S422

S.C. Wang and M.J. Starink, Precipitates and Intermetallic Phases in Precipitation Hardening Al–Cu–Mg–(Li) Based Alloys, Int. Mater. Rev., 2005, 50(4), p 193–215

N.E. Prasad, A. Gokhale, and R. Wanhill, Aluminum-Lithium Alloys, Elsevier, Amsterdam, 2014

J.-X. Xue, J.-X. Liu, G.-J. Zhang, H.-B. Zhang, T. Liu, X.-S. Zhou, and S.-M. Peng, Improvement in Mechanical/Physical Properties of TiC-Based Ceramics Sintered at 1500 C for Inert Matrix Fuels, Scr. Mater., 2016, 114, p 5–8

A. Medjahed, M. Derradji, A. Zegaoui, R. Wu, and B. Li, Processability and Mechanical Properties of Surface-Modified Glass-Fibres/Phthalonitrile Composite and Al–Li Alloy Fibre-Metal-Laminates, Mater. Sci. Technol., 2019, 35(6), p 661–668

A.K. Dewi, S. Yamaguchi, T. Onitsuka, and M. Uno, Thermal Conductivity Estimation of Fully Ceramic Microencapsulated Pellets with ZrO2 as Simulated Particles, J. Nucl. Mater., 2019, 525, p 145–151

K. Mizuuchi, K. Inoue, Y. Agari, Y. Morisada, M. Sugioka, M. Tanaka, T. Takeuchi, J.I. Tani, M. Kawahara, and Y. Makino, Processing of Diamond Particle Dispersed Aluminum Matrix Composites in Continuous Solid–Liquid Co-existent State by SPS and Their Thermal Properties, Compos. Part B Eng., 2011, 42(4), p 825–831

G. Bai, L. Wang, Y. Zhang, X. Wang, J. Wang, M.J. Kim, and H. Zhang, Tailoring Interface Structure and Enhancing Thermal Conductivity of Cu/Diamond Composites by Alloying Boron to the Cu Matrix, Mater. Charact., 2019, 152, p 265–275

Acknowledgments

This paper was supported by National Natural Science Foundation of China (51671063, 51771060, 51871068), Heilongjiang Province Natural Science Foundation (ZD2017010), the Fundamental Research Funds for the Central Universities (HEUCFG201834), Harbin City Application Technology Research and Development Project (2017RAQXJ032).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Medjahed, A., Li, B., Wu, R. et al. Effect of TiC Content on Tensile Properties, Bend Strength, and Thermal Conductivity of Al-Li-Cu-Mg-Zr Alloy/TiC Composites Produced by Accumulative Roll Bonding. J. of Materi Eng and Perform 29, 3253–3263 (2020). https://doi.org/10.1007/s11665-020-04809-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04809-7