Abstract

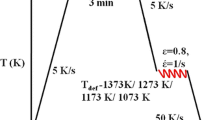

In the present study, the hot deformation behavior and softening mechanism of as-cast S32750 super duplex stainless steel were investigated at low and high strain rates by SEM, EBSD and TEM techniques. Hot compression tests were carried out at the temperature range of 950-1200 °C and strain rates of 0.1, 25 s−1 up to true strain of 1.0 using Gleeble-3800 thermomechanical simulator. The coupling mechanism of the two phases under different deformation conditions determined two types of flow curve characteristics: “yield-point-like” characteristic and typical dynamic recrystallization characteristic. It was found that dynamic recovery and dynamic recrystallization (DRX) were the dominant restoration mechanisms at low and high temperatures, respectively, in austenite phase. The DRX grains were mainly formed through strain-induced boundary migration mechanism located near the austenite/ferrite interface regions. A strong and positive correlation was observed between DRX fraction and the formation of Σ3 twin boundaries. There was an abnormal relationship between DRX fraction and strain rate. The DRX was promoted by increasing strain rate from 0.1 to 25 s−1 at 1200 °C due to weakened strain partitioning and increment in dislocation density, while the strain rate had a minimal effect on DRX fraction at 950 and 1050 °C. A high degree of DRX, approximately 60%, was found within the ferrite phase under all deformation conditions. The softening mechanism within ferrite could be explained by continuous DRX.

Similar content being viewed by others

References

J.O. Nilsson, Super Duplex Stainless Steels, Mater. Sci. Technol. Lond., 1992, 8(8), p 685–700

N. Llorca-Isern, A. Biserova-Tahchieva, I. Lopez-Jimenez, I. Calliari, J.M. Cabrera, and A. Roca, Influence of Severe Plastic Deformation in Phase Transformation Of Superduplex Stainless Steels, J. Mater. Sci., 2019, 54(3), p 2648–2657

G. Argandona, M.V. Biezma, J.M. Berrueta, C. Berlanga, and A. Ruiz, Detection of Secondary Phases in UNS S32760 Superduplex Stainless Steel by Destructive and Non-destructive Techniques, J. Mater. Eng. Perform., 2016, 25(12), p 5269–5279

K.S. de Assis, A.C. Rocha, I.C.P. Margarit-Mattos, F.A.S. Serra, and O.R. Mattos, Practical Aspects on the Use of On-Site Double Loop Electrochemical Potentiodynamic Reactivation Technique (DL-EPR) for Duplex Stainless Steel, Corros. Sci., 2013, 74, p 250–255

B. Zhang, Z. Jiang, H. Li, S. Zhang, H. Feng, and H. Li, Precipitation Behavior and Phase Transformation of Hyper Duplex Stainless Steel UNS S32707 at Nose Temperature, Mater. Charact., 2017, 129, p 31–39

K. Devendranath Ramkumar, D. Mishra, B. Ganesh Raj, M.K. Vignesh, G. Thiruvengatam, S.P. Sudharshan, N. Arivazhagan, N. Sivashanmugam, and A.M. Rabel, Effect of Optimal Weld Parameters in the Microstructure and Mechanical Properties of Autogeneous Gas Tungsten Arc Weldments of Super-Duplex Stainless Steel UNS S32750, Mater. Des., 2015, 66, p 356–365

I. Gutierrez and A. Iza-Mendia, Duplex Stainless Steels, Wiely, Hoboken, 2013, p 30–38

Y. Zhao, Y. Wang, S. Tang, W. Zhang, and Z. Liu, Edge Cracking Prevention in 2507 Super Duplex Stainless Steel by Twin-Roll Strip Casting and Its Microstructure and Properties, J. Mater. Process. Technol., 2019, 266, p 246–254

A. Momeni and K. Dehghani, Hot Working Behavior of 2205 Austenite–Ferrite Duplex Stainless Steel Characterized by Constitutive Equations and Processing Maps, Mater. Sci. Eng. A, 2011, 528(3), p 1448–1454

P. Cizek, The Microstructure Evolution and Softening Processes during High-Temperature Deformation of a 21Cr-10Ni-3Mo Duplex Stainless Steel, Acta Mater., 2016, 106, p 129–143

S. Patra, A. Ghosh, L.K. Singhal, A.S. Podder, J. Sood, V. Kumar, and D. Chakrabarti, Hot Deformation Behavior of As-Cast 2101 Grade Lean Duplex Stainless Steel and the Associated Changes in Microstructure and Crystallographic Texture, Metall. Mater. Trans. A, 2017, 48(1), p 294–313

M. Faccoli and R. Roberti, Study of Hot Deformation Behaviour of 2205 Duplex Stainless Steel through Hot Tension Tests, J. Mater. Sci., 2013, 48(15), p 5196–5203

Y. Zhao, Y. Wang, S. Tang, W. Zhang, and Z. Liu, Development of a Novel Cr21 Lean Duplex Stainless Steel and Its Hot Deformation Behavior, J. Mater. Eng. Perform., 2019, 28(1), p 296–307

J.H. Kang, S.J. Heo, J. Yoo, and Y.C. Kwon, Hot Working Characteristics of S32760 Super Duplex Stainless Steel, J. Mech. Sci. Technol., 2019, 33(6), p 2633–2640

M.K. Mishra, I. Balasundar, A.G. Rao, B.P. Kashyap, and N. Prabhu, On the High Temperature Deformation Behaviour of 2507 Super Duplex Stainless Steel, J. Mater. Eng. Perform., 2017, 26(2), p 802–812

M.H.F.J. Humphreys, Recrystallization and Related Annealing Phenomena, 2nd ed., Elsevier, Oxford, 2004, p 55–56

A. Dehghan-Manshadi and P.D. Hodgson, Effect of δ-Ferrite Co-existence on Hot Deformation and Recrystallization of Austenite, J. Mater. Sci., 2008, 43(18), p 6272–6277

A. Iza-Mendia, A. Piñol-Juez, J.J. Urcola, and I. Gutiérrez, Microstructural and Mechanical Behavior of a Duplex Stainless Steel under Hot Working Conditions, Metall. Mater. Trans. A, 1998, 29(12), p 2975–2986

L. Duprez, B.C.D. Cooman, and N. Akdut, High-Temperature Stress and Strain Partitioning in Duplex Stainless Steel, Z. Metallkd., 2002, 93(3), p 236–243

G.W. Fan, J. Liu, P.D. Han, and G.J. Qiao, Hot Ductility and Microstructure in Casted 2205 Duplex Stainless Steels, Mater. Sci. Eng. A, 2009, 515(1), p 108–112

Y. Yang, H. Qian, and Y. Su, Effect of Mn Addition on Deformation Behaviour of 23% Cr Low Nickel Duplex Stainless Steel, Mater. Charact., 2018, 145, p 606–618

A. Momeni, K. Dehghani, and X.X. Zhang, Mechanical and Microstructural Analysis of 2205 Duplex Stainless Steel under Hot Working Condition, J. Mater. Sci., 2012, 47(6), p 2966–2974

Y. Han, D. Zou, Z. Chen, G. Fan, and W. Zhang, Investigation on Hot Deformation Behavior of 00Cr23Ni4N Duplex Stainless Steel under Medium–High Strain Rates, Mater. Charact., 2011, 62(2), p 198–203

V.D. Cojocaru, D. Răducanu, M.L. Angelescu, A.N. Vintilă, N. Şerban, I. Dan, E.M. Cojocaru, and I. Cinca, Influence of Solution Treatment Duration on Microstructural Features of an Industrial Forged UNS S32750/1.4410/F53 Super Duplex Stainless Steel (SDSS) Alloy, JOM, 2017, 69(8), p 1439–1445

K. Migiakis and G.D. Papadimitriou, Effect of Nitrogen and Nickel on the Microstructure and Mechanical Properties of Plasma Welded UNS S32760 Super-Duplex Stainless Steels, J. Mater. Sci., 2009, 44(23), p 6372–6383

P. Chandramohan, S.S. Mohamed Nazirudeen, and S.S. Ramakrishnan, Studies on Production and Thermo-Mechanical Treatment of 0.32% Nitrogen Alloyed Duplex Stainless Steel, J. Mater. Eng. Perform., 2008, 17(2), p 271–279

A. Pinol-Juez, A. Iza-Mendia, and I. Gutierrez, δ/γ Interface Boundary Sliding as a Mechanism for Strain Accommodation during Hot Deformation in a Duplex Stainless Steel, Metall. Mater. Trans. A, 2000, 31, p 1671–1677

F. Tehovnik, B. Arzensek, B. Arh, D. Skobir, B. Pirnar, and B. Zuzek, Microstructure Evolution in SAF 2507 Super Duplex Stainless Steel, Mater. Technol., 2011, 45(4), p 339–345

M. Ma, H. Ding, Z.-Y. Tang, J.-W. Zhao, Z.-H. Jiang, and G.-W. Fan, Effects of Temperature and Strain Rate on Flow Behavior and Microstructural Evolution of Super Duplex Stainless Steel under Hot Deformation, J. Iron Steel Res. Int., 2016, 23(3), p 244–252

Y.L. Fang, Z.Y. Liu, H.M. Song, and L.Z. Jiang, Hot Deformation Behavior of a New Austenite–Ferrite Duplex Stainless Steel Containing High Content of Nitrogen, Mater. Sci. Eng. A, 2009, 526(1), p 128–133

Y. Cao, H. Di, J. Zhang, J. Zhang, T. Ma, and R.D.K. Misra, An Electron Backscattered Diffraction Study on the Dynamic Recrystallization Behavior of a Nickel-Chromium Alloy (800H) during Hot Deformation, Mater. Sci. Eng. A, 2013, 585, p 71–85

J. Ryś and G. Cempura, Microstructure and Deformation Behavior of Metastable Duplex Stainless Steel at High Rolling Reductions, Mater. Sci. Eng. A, 2017, 700, p 656–666

S. Mandal, A.K. Bhaduri, and V.S. Sarma, Role of Twinning on Dynamic Recrystallization and Microstructure during Moderate to High Strain Rate Hot Deformation of a Ti-Modified Austenitic Stainless Steel, Metall. Mater. Trans. A, 2012, 43(6), p 2056–2068

B. Eghbali, Effect of Strain Rate on the Microstructural Development Through Continuous Dynamic Recrystallization in a Microalloyed Steel, Mater. Sci. Eng. A, 2010, 527(15), p 3402–3406

Y.V.R.K. Prasad and T. Seshacharyulu, Modelling of Hot Deformation for Microstructural Control, Int. Mater. Rev., 1998, 43(6), p 243–258

Y. Liu, H. Yan, X. Wang, and M. Yan, Effect of Hot Deformation Mode on the Microstructure Evolution of Lean Duplex Stainless Steel 2101, Mater. Sci. Eng. A, 2013, 575, p 41–47

A. Dehghan-Manshadi, M.R. Barnett, and P.D. Hodgson, Microstructural Evolution during Hot Deformation of Duplex Stainless Steel, Mater. Sci. Technol. Lond., 2007, 23(12), p 1478–1484

L. Duprez, B.C. De Cooman, and N. Akdut, Flow Stress and Ductility of Duplex Stainless Steel during High-Temperature Torsion Deformation, Metall. Mater. Trans. A, 2002, 33(7), p 1931–1938

S. Atamert and J.E. King, Elemental Partitioning and Microstructural Development in Duplex Stainless Steel Weld Metal, Acta Metall. Mater., 1991, 39(3), p 273–285

T.H. Chen and J.R. Yang, Effects of Solution Treatment and Continuous Cooling on σ-Phase Precipitation in a 2205 Duplex Stainless Steel, Mater. Sci. Eng. A, 2001, 311(1), p 28–41

M.B. Cortie and J.H. Potgieter, The Effect of Temperature and Nitrogen Content on the Partitioning of Alloy Elements in Duplex Stainless Steels, Metall. Mater. Trans. A, 1991, 22(10), p 2173–2179

S. Wang, M. Zhang, H. Wu, and B. Yang, Study on the Dynamic Recrystallization Model and Mechanism of Nuclear Grade 316LN Austenitic Stainless Steel, Mater. Charact., 2016, 118, p 92–101

A. Dehghan-Manshadi, M.R. Barnett, and P.D. Hodgson, Hot Deformation and Recrystallization of Austenitic Stainless Steel: Part I. Dynamic Recrystallization, Metall. Mater. Trans. A, 2008, 39(6), p 1359–1370

M.S. Ghazani and B. Eghbali, Characterization of the Hot Deformation Microstructure of AISI, 321 Austenitic Stainless Steel, Mater. Sci. Eng. A, 2018, 730, p 380–390

H. Jiang, J. Dong, M. Zhang, and Z. Yao, Evolution of Twins and Substructures during Low Strain Rate Hot Deformation and Contribution to Dynamic Recrystallization in Alloy 617B, Mater. Sci. Eng. A, 2016, 649, p 369–381

S.K. Pradhan, S. Mandal, C.N. Athreya, K.A. Babu, B. de Boer, and V.S. Sarma, Influence of Processing Parameters on Dynamic Recrystallization and the Associated Annealing Twin Boundary Evolution in a Nickel Base Superalloy, Mater. Sci. Eng. A, 2017, 700, p 49–58

Y. Wang, W.Z. Shao, L. Zhen, and X.M. Zhang, Microstructure Evolution during Dynamic Recrystallization of Hot Deformed Superalloy 718, Mater. Sci. Eng. A, 2008, 486(1–2), p 321–332

X. Wang, E. Brünger, and G. Gottstein, The Role of Twinning during Dynamic Recrystallization in Alloy 800H, Scr. Mater., 2002, 46(12), p 875–880

F. Qin, H. Zhu, Z. Wang, X. Zhao, W. He, and H. Chen, Dislocation and Twinning Mechanisms for Dynamic Recrystallization of As-Cast Mn18Cr18N Steel, Mater. Sci. Eng. A, 2017, 684, p 634–644

T. Sakai and M. Ohashi, Dislocation Substructures Developed during Dynamic Recrystallisation in Polycrystalline Nickel, Mater. Sci. Techol. Lond., 1990, 6(12), p 1251–1257

W. Wang, F. Brisset, A.L. Helbert, D. Solas, I. Drouelle, M.H. Mathon, and T. Baudin, Influence of Stored Energy on Twin Formation during Primary Recrystallization, Mater. Sci. Eng. A, 2014, 589, p 112–118

H. Mirzadeh and A. Najafizadeh, The Rate of Dynamic Recrystallization in 17-4 PH Stainless Steel, Mater. Des., 2010, 31(10), p 4577–4583

S. Mitsche, C. Sommitsch, D. Huber, M. Stockinger, and P. Poelt, Assessment of Dynamic Softening Mechanisms in Allvac® 718Plus™ by EBSD Analysis, Mater. Sci. Eng. A, 2011, 528(10), p 3754–3760

P. Cizek, B.P. Wynne, and W.M. Rainforth, EBSD Investigation of the Microstructure and Texture Characteristics of Hot Deformed Duplex Stainless Steel, J. Microsc., 2006, 222(2), p 85–96

R.Z. Wang and T.C. Lei, Dynamic Recrystallization of Ferrite in a Low Carbon Steel during Hot Rolling in the (F+A) Two-Phase Region, Scr. Metall. Mater., 1994, 31, p 1193–1196

A. Belyakov, Y. Kimura, and K. Tsuzaki, Microstructure Evolution in Dual-Phase Stainless Steel during Severe Deformation, Acta Mater., 2006, 54(9), p 2521–2532

B. Eghbali, A. Abdollah-zadeh, and P.D. Hodgson, Dynamic Softening of Ferrite during Large Strain Warm Deformation of a Plain-Carbon Steel, Mater. Sci. Eng. A, 2007, 462(1–2), p 259–263

Acknowledgments

The research was supported by National Key R&D program of China (No. 2016YFB0300201), National High-tech R&D Program of China (No. 2015AA034301), Key Scientific Research Project in Shanxi Province (Grant Nos. MC2016-06, 201603D111004, 20181101014 and 201805D121003), Research Project Supported by Shanxi Scholarship Council of China (2017029) and Patent Promotion and Implement Found of Shanxi Province (20171003).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Min, W., Baosheng, L., Shoulu, Z. et al. Hot Deformation Behavior and Softening Mechanism of As-Cast S32750 Super Duplex Stainless Steel at Low and High Strain Rates. J. of Materi Eng and Perform 29, 727–738 (2020). https://doi.org/10.1007/s11665-020-04571-w

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04571-w