Abstract

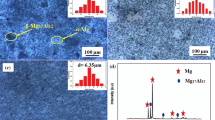

To improve the surface properties and performance, a grain-refined surface layer was produced on AZ31B Mg alloy by a newly developed surface nano-crystallization and hardening process called surface mechanical rolling grinding treatment (SMRGT). The grain size refinement and minimal surface hardening were confirmed by the microstructure observations, XRD results and microhardness tests and were attributed to the multipass small strain-induced plastic deformation of the material during the SMRGT process. A nano-grain surface layer (average grain size of ~ 100 nm) and a graded microhardness variation (average ~ 113 HV adjacent to surface) along the thickness direction were generated. The Ecorr values of the as-SMRGTed samples were − 1.43 ± 0.03 and − 1.42 ± 0.02 V, increasing by ~ 30-40 mV compared with the values of the as-received (AR) sample (− 1.46 ± 0.02 V), corresponding to icorr ranging from 3.0 × 10−5 to 1.0 × 10−5 and 5.0 × 10−6 A/cm2, respectively. Charge transfer resistance (Rct) increased from 93.4 to 292.4 and 578.3 Ω (~ 3-6 times) with the increasing number of SMRGT passes. The corrosion resistance improvement was attributed mainly to the dramatic strain-induced surface grain refinement and minimal surface hardening that give rise to a more smooth and densely packed surface state.

Similar content being viewed by others

References

C.S. Wu, Z. Zhang, and F.H. Cao, Study on the Anodizing of AZ31 Magnesium Alloys in Alkaline Borate Solutions, Appl. Surf. Sci., 2007, 253(8), p 3893–3898

J.E. Gray and B. Luan, Protective Coatings on Magnesium and its Alloys—A Critical Review, J. Alloy. Compd., 2002, 336(1–2), p 88–113

H. Wang, Y. Estrin, and H. Fu, The Effect of Pre-processing and Grain Structure on the Biocorrosion and Fatigue Resistance of Magnesium Alloy AZ31, Adv. Eng. Mater., 2010, 9(11), p 967–972

A. Loos, R. Rohde, and A. Haverich, In Vitro and in Vivo Biocompatibility Testing of Absorbable Metal Stents, Macromol. Symp., 2007, 253(1), p 103–108

X. Gu, Y. Zheng, and Y. Cheng, In Vitro Corrosion and Biocompatibility of Binary Magnesium Alloys, Biomaterials, 2009, 30(4), p 484–498

M. Liu, P.J. Uggowitzer, and P. Schmutz, Calculated Phase Diagrams, Iron Tolerance Limits, and Corrosion of Mg-Al Alloys, JOM, 2008, 60(12), p 39–44

K.U. Kainer, P.B. Srinivasan, and C. Blawert, Corrosion of Magnesium and its Alloys, Shreirs Corrosion, 2010, 51(8), p 2011–2041

G.L. Makar and J. Kruger, Corrosion of Magnesium, Int. Mater. Rev., 1993, 38(3), p 138–153

M. Moravej and D. Mantovani, Biodegradable Metals for Cardiovascular Stent Application: Interests and New Opportunities, Int. J. Mol. Sci., 2011, 12(7), p 4250–4270

G. Song, Control of Biodegradation of Biocompatable Magnesium Alloys, Corros. Sci., 2007, 49(4), p 1696–1701

P.W. Serruys, P. de Jaegere, and F. Kiemeneij, A comparison of Balloon-Expandable-Stent Implantation with Balloon Angioplasty in Patients with Coronary Artery Disease, N. Engl. J. Med., 1994, 331(8), p 489–495

S.R. Agnew and J.F. Nie, Preface to the Viewpoint Set On: The Current State of Magnesium Alloy Science and Technology, Scripta Mater., 2010, 63(7), p 671–673

B.L. Mordike and T. Ebert, Magnesium Properties-Applications-Potential, Mater. Sci. Eng., A, 2001, 302(1), p 37–45

K.Y. Chiu, M.H. Wong, and F.T. Cheng, Characterization and Corrosion Studies of Fluoride Conversion Coating on Degradable Mg Implants, Surf. Coat. Tech., 2007, 202(3), p 590–598

G.L. Song and Z. Shi, Anodization and Corrosion of Magnesium (Mg) Alloys, Corros. Magnes. Alloy., 2001, 41, p 565–614

Y. Li, T. Zhang, and F. Wang, Effect of Microcrystallization on Corrosion Resistance of AZ91D Alloy, Electrochim. Acta, 2006, 51(14), p 2845–2850

T. Balusamy, S. Kumar, and T.S.N.S. Narayanan, Effect of Surface Nanocrystallization on the Corrosion Behaviour of AISI, 409 Stainless Steel, Corros. Sci., 2010, 52(11), p 3826–3834

P.S. Prevéy, J. Telesman, and T. Gabb, FOD Resistance and Fatigue Crack Arrest in Low Plasticity Burnished IN718, Proceedings of the 5th National High Cycle Fatigue Conf., Chandler, AZ. 2000, 3, p 7–9

A.H. Clauer, Laser Shock Peening for Fatigue Resistance, Surface Performance of Titanium, JK Gregory, PA, 1996, p 217–230

T. Watanabe and K. Hattori, Effect of ultrasonic shot peening on fatigue strength of high strength steel, Proceedings ICSP8, Garmisch-Partenkirchen, Germany, 2002, p 305–310

T. Wang, J. Yu, and B. Dong, Surface Nanocrystallization Induced by Shot Peening and its Effect on Corrosion Resistance of 1Cr18Ni9Ti Stainless Steel, Surf. Coat. Tech., 2006, 200(16–17), p 4777–4781

C. Op”t Hoog, N. Birbilis, and Y. Estrin, Corrosion of pure Mg as a Function of Grain Size and Processing Route and Dagger, Adv. Eng. Mater., 2010, 10(6), p 579–582

N. Birbilis, K.D. Ralston, and S. Virtanen, Grain Character Influences on Corrosion of ECAPed Pure Magnesium, Corros. Eng. Sci. Techn., 2010, 45(3), p 224–230

D. Song, A. Ma, and J. Jiang, Corrosion Behavior of Equal-Channel-Angular-Pressed Pure Magnesium in NaCl Aqueous Solution, Corros. Sci., 2010, 52(2), p 481–490

G. Ben-Hamu, D. Eliezer, and L. Wagner, The Relation Between Severe Plastic Deformation Microstructure and Corrosion Behavior of AZ31 Magnesium Alloy, J. Alloy. Compd., 2009, 468(1), p 222–229

D. Song, A.B. Ma, and J.H. Jiang, Corrosion Behaviour of Bulk Ultra-Fine Grained AZ91D Magnesium Alloy Fabricated by Equal-Channel Angular Pressing, Corros. Sci., 2011, 53(1), p 362–373

B.Q. Chen, G.F. Zhang, L.J. Zhang, and T.T. Xu, A New Approach of a Gradient Nanograined Surface Layer for Mg-3Al-1Zn Alloy Induced by SMRGT, Int. J. Adv. Manuf. Tech., 2018, 94, p 2659–2665

W.T. Huo, W. Zhang, J.W. Lu, and Y.S. Zhang, Simultaneously Enhanced Strength and Corrosion Resistance of Mg-3Al-1Zn Alloy Sheets with Nano-Grained Surface Layer Produced by Sliding Friction Treatment, J. Alloy. Compd., 2017, 720, p 324–331

A.M. Hassan and A.M. Maqableh, The Effects of Initial Burnishing Parameters on Non-Ferrous Components, J. Mater. Process Tech., 2000, 102(1–3), p 115–121

M. Janeček and F. Chmelík, Mechanisms of Plastic Deformation in AZ31 Magnesium Alloy Investigated by Acoustic Emission and Electron Microscopy, Magnesium Alloys-Design, Processing and Properties. Frank Czerwinski (Ed.), ISBN: 978-953-307-520-4 InTech, 2011, p 43–68

G.R. Argade, S.K. Panigrahi, and R.S. Mishra, Effects of Grain Size on the Corrosion Resistance of Wrought Magnesium Alloys Containing Neodymium, Corros. Sci., 2012, 58(5), p p145–p151

G. Song, D. StJohn, and T. Abbott, Corrosion Behaviour of a Pressure Die Cast Magnesium Alloy, J. Cast. Metal Res., 2005, 18(3), p 174–180

G.L. Song and Z.Q. Xu, The Surface, Microstructure and Corrosion of Magnesium Alloy AZ31 Sheet, Electrochim. Acta, 2010, 55(13), p 4148–4161

C. op’t Hoog, N. Birbilis, and M.X. Zhang, Surface Grain Size Effects on the Corrosion of Magnesium, Key Eng. Mater., 2008, 384, p 229–240

H.S. Kim, G.H. Kim, H. Kim, and W.J. Kim, Enhanced Corrosion Resistance of High Strength Mg–3Al–1Zn Alloy Sheets with Ultrafine Grains in a Phosphate-Buffered Saline Solution, Corros. Sci., 2013, 74(3), p 139–148

G.L. Makar and K. Kruger, Corrosion Studies of Rapidly Solidified Magnesium Alloys, J. Electrochem. Soc., 1990, 137(2), p 414–421

G. Song, A. Atrens, and D. StJohn, The Anodic Dissolution of Magnesium in Chloride and Sulphate Solutions, Corros. Sci., 1997, 39(10–11), p 1981–2004

N. Pebre, T. Picaud, and M. Durprat, Evaluation of Corrosion Performance of Coated Steel by the Impedance Technique, Corros. Sci., 1989, 29(9), p 1073–1086

G. Ruhi, O.P. Modi, and I.B. Singh, Corrosion Behaviour of Nano Structured Sol-Gel Alumina Coated 9Cr-1Mo Ferritic Steel in Chloride Bearing Environments, Surf. Coat. Tech., 2009, 204(3), p 359–365

L. Tomcsanyi, K. Tomcsanyi, and I. Varga, Electrochemical Study of the Pitting Corrosion of Aluminium and its Alloys—II, Study of the Interaction of Chloride Ions with a Passive Film on Aluminium and Initiation of Pitting Corrosion, Electrochim. Acta, 1989, 34(6), p 855–859

L. Lu, T. Liu, J. Chen, and Z. Wang, Microstructure and Corrosion Behavior of AZ31 Alloys Prepared by Dual Directional Extrusion, Mater. Des., 2012, 36, p 687–693

Acknowledgments

The Special Welding Teaching and Research section of State Key Laboratory for Mechanical Behavior of Materials of Xi’an Jiaotong University is acknowledged. The authors thank Dr. C. Xin, F. Zhou, Prof. L.J. Zhang and J. Peng for careful reading and valuable criticisms that improved this manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, B., Xin, C., Zhang, G. et al. Grain-Refined Microstructure and Hard Surface Layer Produced by SMRGT Process for Improved Corrosion Behavior of Mg-3Al-1Zn Alloy. J. of Materi Eng and Perform 28, 1253–1262 (2019). https://doi.org/10.1007/s11665-019-3874-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-3874-4