Abstract

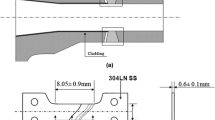

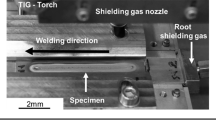

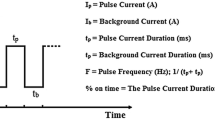

Several engineering components are fabricated by joining similar or dissimilar materials. In the present investigation, welded joints between low alloy steel and austenitic stainless steel were considered. This assembly is one of the critical components in the heat transport system of water-cooled reactors of nuclear power plants. 309L austenitic stainless steel and IN 182 alloys were used for buttering low alloy steel during fabrication of joints. Weld metal was 308L austenitic stainless steel and IN 182, respectively, for the two assemblies. Buttering by 309L SS was performed by gas tungsten arc welding, and the same was done by shield metal arc welding at the time of applying IN 182. Joining of 304L SS and buttered assembly in both the cases was carried out by shield metal arc welding. Evaluation of Vickers micro-hardness was done across the weld centerline for both joints. Microstructure of different regions was examined for the joints. Apart from conventional destructive tests, ultrasonic evaluation of joints was also carried out to ensure weld integrity. In this respect, ultrasonic velocity in longitudinal and shear mode was measured along the transverse direction of the weld. Young’s modulus was determined using ultrasonic tests as well as from the average hardness of different regions. The obtained Young’s modulus by two different techniques revealed satisfactory co-relation. The Young’s modulus obtained from ultrasonic measurements was used to determine the yield strength of different regions across the welds. This technique proved to be useful in identifying the failure prone area across the welded joint.

Reprinted with permission, Ref 2

Hardness data have been reprinted with permission, Ref 2

Similar content being viewed by others

References

R. Nivas, P.K. Singh, G. Das, S.K. Das, S. Kumar, B. Mahato, K. Sivaprasad, and M. Ghosh, A Comparative Study on Microstructure and Mechanical Properties Near Interface for Dissimilar Materials During Conventional v-Groove and Narrow Gap Welding, J. Manuf. Process., 2017, 25, p 274–283

M. Ghosh, R. Santosh, S.K. Das, G. Das, B. Mahato, J. Korody, S. Kumar, and P.K. Singh, Effect of Structural Heterogeneity on In Situ Deformation of Dissimilar Weld Between Ferritic and austenitic Steel, Metall. Mater. Trans. A, 2015, 46, p 3555–3568

Z.R. Chen and Y.H. Lu, TEM Observation of Martensite Layer at the Weld Interface of an A508III, to Inconel 82 Dissimilar Metal Weld Joint, Metall. Mater. Trans. A, 2015, 46, p 5494–5498

J.W. Kim, K. Lee, J.S. Kim, and T.S. Byun, Local Mechanical Properties of Alloy 82/182 Dissimilar Weld Joint Between SA508 Gr.1a and F316 SS at RT and 320 °C, J. Nucl. Mater., 2009, 384, p 212–221

H.P. Seifert, S. Ritter, T. Shoji, Q.J. Peng, Y. Takeda, and Z.P. Lu, Environmentally-Assisted Cracking Behavior in the Transition Region of an Alloy182/SA 508 Cl. 2 Dissimilar Metal Weld Joint in Simulated Boiling Water Reactor Normal Water Chemistry Environment, J. Nucl. Mater., 2008, 378, p 197–210

J.M. Farley, J.L. Thompson, and B.J. Dikstra, Nondestructive testing to avoid weld failures: a review, in International Conference on Weld Failures, ed. by J.D. Harrison (The Welding Institute, London, 1988)

T. Martin, S. Knaak, and J. Aktaa, Immersion ultrasonic testing on EUROFER welded joints for determination of the minimum detectable flaw size, in Proceedings of DGZfP Conference, 10-12 May, Erfurt, Germany (2010)

M. Tabatabaeipour, J. Hettler, S. Delrue, and K.V.D. Abeele, Non-destructive Ultrasonic Examination of Root Defects in Friction Stir Welded Butt-Joints, NDT&E International, 2016, 80, p 23–34

P.B. Nagy and L. Adler, Ultrasonic NDE of Solid-State Bonds: Inertia and Friction Welds, J. Nondestruct. Eval., 1988, 7, p 199–215

Y. Javadi and M.A. Najafabadi, Comparison Between Contact and Immersion Ultrasonic Method to Evaluate Welding Residual Stresses of Dissimilar Joints, Mater. Des., 2013, 47, p 473–482

E. Jasiuniene, V. Samaitis, L. Mazeika, and R. Sanderson, 3D Ultrasonic Non-destructive Evaluation of Spot Welds Using an Enhanced Total Focusing Method, J. Mater. Eng. Perform., 2015, 24, p 825–831

K. Sharma, H.K. Khandelwal, V. Bhasin, and R. Chhibber, Application of Ball Indentation Technique for Mechanical Properties Estimation of Bi-metallic Weld, Adv. Mater. Res., 2012, 585, p 342–346

K.K. Vaze, P.K. Singh, and V. Bhasin, Challenges in materials and welding of main heat transport system piping of AHWR, in Proceedings of 2nd International Conference on Advances in Nuclear Materials (2011), https://inis.iaea.org/search/search.aspx?orig_q=RN:43001715. Accessed 3 Jan 2019

D.E. Bray and R.K. Stanley, Nondestructive Evaluation: A Tool in Design, Manufacturing and Service, CRC Press, Boca Raton, 1999, ISBN 0-8493-2655-9

D. Tabor, The Hardness of Metals, Clarendon Press, Oxford, 1951, p 102

J.R. Cahoon, W.H. Broughton, and A.R. Kutzak, The Determination of Yield Strength from Hardness Measurements, Metall. Trans., 1971, 2, p 1979–1983

C. Jang, J. Lee, J.S. Kimand, and T.E. Jin, Mechanical Property Variation Within Inconel 82/182 Dissimilar Weld Between Low Alloy Steel and 316 Stainless Steel, Int. J. Press. Vessel Pip., 2008, 85, p 635–646

W.D. Callister, Jr., Fundamentals of Materials Science and Engineering, 2nd ed., Wiley, New York, 2005, p 199ISBN 978-0-471-47104-4

Mechanical Properties and Performance of Materials, Chapter 5, http://courses.washington.edu/me354a/chap5.pdf. Accessed 3 Jan 2019

M. Aghaie-Khafri, F. Honarvar, and S. Zanganeh, Characterization of Grain Size and Yield Strength in AISI, 301 Stainless Steel Using Ultrasonic Attenuation Measurements, J. Nondestruct. Eval., 2012, 31, p 191–196

B. Ahn, S.S. Lee, S.T. Hong, H.C. Kim, and S.L. Kang, Application of the Acoustic Resonance Method to Evaluate the Grain Size of Low Carbon Steels, NDT&E Int., 1999, 32, p 85–89

W.N. Reynolds and R.L. Smith, Ultrasonic Wave Attenuation Spectra in Steels, J. Phys. D Appl. Phys., 1984, 17, p 109–116

J.R. Tomlinson, A.R. Wagg, and M.J. Whittle, Ultrasonic Inspection of austenitic Welds, Br. J. NDT, 1980, 22, p 119–127

R. Santosh, S.K. Das, G. Das, J. Korody, S. Kumar, P.K. Singh, and M. Ghosh, Three-Dimensional Thermomechanical Simulation and Experimental Validation on Failure of Dissimilar Material Welds, Metall. Mater. Trans. A, 2016, 47A, p 3511–3521

H.S. Hosseini, M. Shamanian, and A. Kermanpur, Characterization of Microstructures and Mechanical Properties of Inconel 617/310 Stainless Steel Dissimilar Weld, Mater. Charact., 2011, 62, p 425–431

H. Ming, R. Zhou, Z. Zhang, J. Wang, E.H. Han, W. Ke, and M. Su, Microstructure, Local Mechanical Properties and Stress Corrosion Cracking Susceptibility of an SA508-52M-316LN Safe-End Dissimilar Metal Weld Joint by GTAW, Mater. Sci. Eng. A, 2016, 669, p 279–290

D.W. Rathod, P.K. Singh, S. Pandey, and S. Aravindan, Effect of Butter Layer Buttering on Microstructure and Mechanical Properties of Dissimilar Metal Weld Joints for Nuclear Plant Application, Mater. Sci. Eng. A, 2016, 666, p 100–113

Acknowledgments

The authors are grateful to the Director, CSIR-NML, for providing infrastructural facilities to carry out the investigation and permission to publish the work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghosh, A., Sahu, M., Singh, P.K. et al. Assessment of Mechanical Properties for Dissimilar Metal Welds: A Nondestructive Approach. J. of Materi Eng and Perform 28, 900–907 (2019). https://doi.org/10.1007/s11665-019-3867-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-3867-3