Abstract

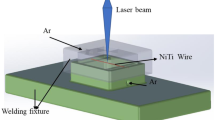

Bead-on-plate laser welding was carried out on 1-mm-thick Nitinol sheets at different heat input values. The variations in weld-bead geometry and variations in microstructures across the bead were studied. The effects of heat input on surface layer composition of the welded samples, corrosion properties and phase transformation temperature were examined. From x-ray photoelectron spectroscopy (XPS), it was clear that relative intensity of elemental Ni peak was higher in parent material and the oxidation state of Ti was Ti4+. It was further observed from Auger electron spectroscopy (AES) that the Ti to Ni ratio on the top surface of the welded samples was more than 1, and as a result of this the stability of TiO2 layer was enhanced, which eventually helped to improve the corrosion property of the welded samples. The polarization resistance of the welded samples was increased by more than ten times compared to that of the un-welded samples. From differential scanning calorimetry (DSC), it became evident that phase transformation temperatures got changed due to welding.

Similar content being viewed by others

Change history

18 June 2019

Please note that the correct sequence of authors is “Susmita Datta, Mohammad Shahid Raza, Partha Saha, Dilip Kumar Pratihar”.

References

N.J. Nollu, H.W. Kerr, Y. Zhou, and J. Xie, Laser Weldability of Pt and Ti Alloys, Mater. Sci. Eng. A, 2005, 397(1-2), p 8–15

C. Maletta, A. Falvo, F. Furgiuele, G. Barbieri, and M. Brandizzi, Fracture Behaviour of Nickel-titanium Laser Welded Joints, J. Mater. Eng. Perform., 2009, 18(5-6), p 569–574

H. Gugel, A. Schuermann, and W. Theisen, Laser Welding of NiTi Wires, Mater. Sci. Eng. A, 2008, 481, p 668–671

B. Tam, M.I. Khan, and Y. Zhou, Mechanical and Functional Properties of Laser-welded Ti-55.8 Wt Pct Ni NiTinol Wires, Metall. Mater. Trans. A, 2011, 42(8), p 2166–2175

C.W. Chan and H.C. Man, Laser Welding of Thin Foil Nickel-Titanium Shape Memory Alloy, Opt. Lasers Eng., 2011, 49(1), p 121–126

C.W. Chan, H.C. Man, and T.M. Yue, Effects of Process Parameters upon the Shape Memory and Pseudo-elastic Behaviors of Laser-welded NiTi Thin Foil, Metall. Mater. Trans. A, 2011, 42(8), p 2264–2270

M. Dadfar, M.H. Fathi, F. Karimzadeh, M.R. Dadfar, and A. Saatchi, Effect of TIG Welding on Corrosion Behavior of 316L Stainless steel, Mater. Lett., 2007, 61(11-12), p 2343–2346

N. Amanat, N.L. James, and D.R. McKenzie, Welding Methods for Joining Thermoplastic Polymers for the Hermetic Enclosure of Medical Devices, Med. Eng. Phys., 2010, 32(7), p 690–699

M.F. Nichols, The Challenges for Hermetic Encapsulation of Implanted Devices - a Review, Crit. Rev. Biomed. Eng., 1994, 22(1), p 39–67

W.H. Ko, Packaging of Microfabricated Devices and Systems, Mater. Chem. Phys., 1995, 42(3), p 169–175

I. Milošev, T. Kosec, and H.H. Strehblow, XPS and EIS Study of The Passive Film Formed on Orthopaedic Ti-6Al-7Nb Alloy in Hank’s Physiological Solution, Electrochim. Acta, 2008, 53(9), p 3547–3558

J.C. Wataha, N.L. O’Dell, B.B. Singh, M. Ghazi, G.M. Whitford, and P.E. Lockwood, Relating Nickel-induced Tissue Inflammation to Nickel release in Vivo, J. Biomed. Mater. Res. Part A, 2001, 58(5), p 537–544

L. Peltonen, Nickel Sensitivity in the General Population, Contact Dermatitis, 1979, 5(1), p 27–32

C.L. Dunlap, S.K. Vincent, and B.F. Barker, Allergic Reaction to Orthodontic Wire: Report of Case, J. Am. Dental Assoc., 1989, 118(4), p 449–450

G. Rondelli, B. Vicentini, and A. Cigada, The Corrosion Behaviour of Nickel Titanium Shape Memory Alloys, Corros. Sci., 1990, 30(8-9), p 805–812

G. Rondelli, Corrosion Resistance Tests on NiTi Shape Memory Alloy, Biomaterials, 1996, 17(20), p 2003–2008

S.A. Shabalovskaya, G.C. Rondelli, A.L. Undisz, J.W. Anderegg, T.D. Burleigh, and M.E. Rettenmayr, The Electrochemical Characteristics of Native Nitinol Surfaces, Biomaterials, 2009, 30(22), p 3662–3671

T. Kanemura, K.I. Yokoyama, and J.I. Sakai, Effects of Acid Type on Corrosion and Fracture Behavior of Ni-Ti Superelastic Alloy Under Sustained Tensile Load in Physiological Saline Solution Containing Hydrogen Peroxide, Corros. Sci., 2008, 50(10), p 2785–2795

Y. Okazaki and E. Gotoh, Metal Release from Stainless Steel, Co-Cr-Mo-Ni-Fe and Ni-Ti Alloys in Vascular Implants, Corros. Sci., 2008, 50(12), p 3429–3438

N. Figueira, T.M. Silva, M.J. Carmezim, and J.C.S. Fernandes, Corrosion Behaviour of NiTi Alloy, Electrochim. Acta, 2009, 54(3), p 921–926

Z.D. Cui, H.C. Man, and X.J. Yang, The Corrosion and Nickel Release Behavior of Laser Surface-melted NiTi Shape Memory Alloy in Hanks’ Solution, Surf. Coat. Technol., 2005, 192(2-3), p 347–353

D. Starosvetsky and I. Gotman, Corrosion Behavior of Titanium Nitride Coated Ni-Ti Shape Memory Surgical Alloy, Biomaterials, 2001, 22(13), p 1853–1859

C. Liu, P.K. Chu, G. Lin, and D. Yang, Effects of Ti/TiN Multilayer on Corrosion Resistance of Nickel-Titanium Orthodontic Brackets in Artificial Saliva, Corros. Sci., 2007, 49(10), p 3783–3796

X.J. Yan, D.Z. Yang, and X.P. Liu, Corrosion Behavior of a Laser-welded NiTi Shape Memory Alloy, Mater. Charact., 2007, 58(7), p 623–628. https://doi.org/10.1016/j.matchar.2006.07.010

Y.T. Hsu, Y.R. Wang, S.K. Wu, and C. Chen, Effect of CO2 Laser Welding on the Shape-memory and Corrosion Characteristics of TiNi Alloys, Metall. Mater. Trans. A, 2001, 32(3), p 569–576

S.A. Shabalovskaya, H. Tian, J.W. Anderegg, D.U. Schryvers, W.U. Carroll, and J. Van Humbeeck, The Influence of Surface Oxides on the Distribution and Release of Nickel from Nitinol Wires, Biomaterials, 2009, 30(4), p 468–477

S.A. Shabalovskaya, Surface, Corrosion and Biocompatibility Aspects of Nitinol as an Implant Material, Bio-med. Mater. Eng., 2002, 12(1), p 69–109

S. Shabalovskaya, J. Anderegg, and J. Van Humbeeck, Critical Overview of Nitinol Surfaces and Their Modifications for Medical Applications, Acta Biomater., 2008, 4(3), p 447–467

S. Shabalovskaya, J. Anderegg, G. Rondelli, W. Vanderlinden, and S. De Feyter, Comparative in Vitro performances of Bare Nitinol Surfaces, Bio-Med. Mater. Eng., 2008, 18(1), p 1–14

C.W. Chan, H.C. Man, and T.M. Yue, Effect of Post-weld Heat-treatment on the Oxide Film and Corrosion Behaviour of Laser-welded Shape Memory NiTi Wires, Corros. Sci., 2012, 56, p 158–167

A. Tuissi, S. Besseghini, T. Ranucci, F. Squatrito, and M. Pozzi, Effect of Nd-YAG Laser Welding on the Functional Properties of the Ni-49.6 at.% Ti, Mater. Sci. Eng. A, 1999, 273, p 813–817

A. Falvo, F.M. Furgiuele, and C. Maletta, Functional Behaviour of a NiTi-welded Joint: Two-way Shape Memory Effect, Mater. Sci. Eng. A, 2008, 481, p 647–650

J.P. Oliveira, R.M. Miranda, N. Schell, and F.B. Fernandes, High Strain and Long Duration Cycling Behavior of Laser Welded NiTi Sheets, Int. J. Fatigue, 2016, 83, p 195–200

A. Falvo, F.M. Furgiuele, and C. Maletta, Laser Welding of a NiTi alloy: Mechanical and Shape memory Behaviour, Mater. Sci. Eng. A, 2005, 412(1-2), p 235–240

L.A. Vieira, F.B. Fernandes, R.M. Miranda, R.J.C. Silva, L. Quintino, A. Cuesta, and J.L. Ocaña, Mechanical Behaviour of Nd: YAG Laser Welded Superelastic NiTi, Mater. Sci. Eng. A, 2011, 528(16-17), p 5560–5565

G.R. Mirshekari, A. Kermanpur, A. Saatchi, S.K. Sadrnezhaad, and A.P. Soleymani, Microstructure, Cyclic Deformation and Corrosion Behavior of Laser Welded NiTi shape Memory Wires, J. Mater. Eng. Perform., 2015, 24(9), p 3356–3364

Z. Zeng, M. Yang, J.P. Oliveira, D. Song, and B. Peng, Laser Welding of NiTi Shape Memory Alloy Wires and Tubes for Multi-functional Design Applications, Smart Mater. Struct., 2016, 25(8), p 085001

J.P. Oliveira, F.B. Fernandes, R.M. Miranda, N. Schell, and J.L. Ocaña, Effect of Laser Welding Parameters on the Austenite and Martensite Phase Fractions of NiTi, Mater. Charact., 2016, 119, p 148–151

J.P. Oliveira, F.B. Fernandes, R.M. Miranda, N. Schell, and J.L. Ocaña, Residual Stress Analysis in Laser Welded NiTi Sheets Using Synchrotron X-ray Diffraction, Mater. Des., 2016, 100, p 180–187

J.P. Oliveira, D. Barbosa, F.B. Fernandes, and R.M. Miranda, Tungsten Inert Gas (TIG) Welding of Ni-rich NiTi Plates: Functional Behavior, Smart Mater. Struct., 2016, 25(3), p 03LT01

A. Ikai, K. Kimura, and H. Tobushi, TIG Welding and Shape Memory Effect of TiNi Shape Memory Alloy, J. Intell. Mater. Syst. Struct., 1996, 7(6), p 646–655

W. Zhang, S.S. Ao, J.P. Oliveira, Z. Zeng, Z. Luo, and Z.Z. Hao, Corrigendum: Effect of Ultrasonic Spot Welding on the Mechanical Behaviour of NiTi Shape Memory Alloys, Smart Mater. Struct., 2018, 27(10), p 109501

S.M. Prabu, H.C. Madhu, C.S. Perugu, K. Akash, P.A. Kumar, S.V. Kailas, M. Anbarasu, and I.A. Palani, Microstructure, Mechanical Properties and Shape Memory Behaviour of Friction Stir Welded Nitinol, Mater. Sci. Eng. A, 2017, 693, p 233–236

S.M. Prabu, H.C. Madhu, C.S. Perugu, K. Akash, R. Mithun, P.A. Kumar, S.V. Kailas, M. Anbarasu, and I.A. Palani, Shape Memory Effect, Temperature Distribution and Mechanical Properties of Friction Stir Welded Nitinol, J. Alloys Compd., 2019, 776, p 334–345

Z. Zeng, B. Panton, J.P. Oliveira, A. Han, and Y.N. Zhou, Dissimilar Laser Welding of NiTi Shape Memory Alloy and Copper, Smart Mater. Struct., 2015, 24(12), p 125036

J.P. Oliveira, Z. Zeng, C. Andrei, F.B. Fernandes, R.M. Miranda, A.J. Ramirez, T. Omori, and N. Zhou, Dissimilar Laser Welding of Superelastic NiTi and CuAlMn Shape Memory Alloys, Mater. Des., 2017, 128, p 166–175

R.M. Miranda, E. Assunção, R.J. Silva, J.P. Oliveira, and L. Quintino, Fiber Laser Welding of NiTi to Ti-6Al-4V, Int. J. Adv. Manuf. Technol., 2015, 81(9-12), p 1533–1538

Z. Zeng, J.P. Oliveira, M. Yang, D. Song, and B. Peng, Functional Fatigue Behavior of NiTi-Cu Dissimilar Laser Welds, Mater. Des., 2017, 114, p 282–287

J.P. Oliveira, B. Panton, Z. Zeng, C.M. Andrei, Y. Zhou, R.M. Miranda, and F.B. Fernandes, Laser Joining of NiTi to Ti6Al4 V Using a Niobium Interlayer, Acta Mater., 2016, 105, p 9–15

M. Daly, A. Pequegnat, Y.N. Zhou, and M.I. Khan, Fabrication of a Novel Laser-Processed NiTi Shape Memory Microgripper with Enhanced Thermomechanical Functionality, J. Intell. Mater. Syst. Struct., 2013, 24(8), p 984–990

B. Panton, J.P. Oliveira, Z. Zeng, Y.N. Zhou, and M.I. Khan, Thermomechanical Fatigue of Post-weld Heat Treated NiTi Shape Memory Alloy Wires, Int. J. Fatigue, 2016, 92, p 1–7

R. Chakraborty, V.S. Seesala, M. Sen, S. Sengupta, S. Dhara, P. Saha, K. Das, and S. Das, MWCNT Reinforced Bone Like Calcium Phosphate—Hydroxyapatite Composite Coating Developed Through Pulsed Electrodeposition with Varying Amount of Apatite Phase and Crystallinity to Promote Superior Osteoconduction, Cytocompatibility and Corrosion Protection Performance Compared to Bare Metallic Implant Surface, Surf. Coat. Technol., 2017, 325, p 496–514

J.F. Moulder, W.F. Stickle, P.E. Sobol, and K.D. Bomben, Handbook of X-Ray Photoelectron Spectroscopy, Perkin-Elmer Corporation, Eden Prairie, MN, 1992

A. Pequegnat, A. Michael, J. Wang, K. Lian, Y. Zhou, and A.N.D.M.I. Khan, Surface Characterizations of Laser modified Biomedical Grade NiTi Shape Memory Alloys, Mater. Sci. Eng. C, 2015, 50, p 367–378

H.C. Man, Z.D. Cui, and A.N.D.T.M. Yue, Corrosion Properties of Laser Surface Melted NiTi Shape Memory Alloy, Scr. Mater., 2001, 45(12), p 1447–1453

M.I. Khan and Y. Zhou, Effects of Local Phase Conversion on the Tensile Loading of Pulsed Nd: YAG Laser Processed Nitinol, Mater. Sci. Eng. A, 2010, 527(23), p 6235–6238

W.J. Lorenz and F. Mansfeld, Determination of Corrosion Rates by Electrochemical DC and AC Methods, Corros. Sci., 1981, 21(9-10), p 647–672

J. Frenzel, E.P. George, A. Dlouhy, C. Somsen, M.X. Wagner, and G. Eggeler, Influence of Ni on Martensitic Phase Transformations in NiTi Shape Memory Alloys, Acta Mater., 2010, 58(9), p 3444–3458

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Saha, P., Datta, S., Raza, M.S. et al. Effects of Heat Input on Weld-Bead Geometry, Surface Chemical Composition, Corrosion Behavior and Thermal Properties of Fiber Laser-Welded Nitinol Shape Memory Alloy. J. of Materi Eng and Perform 28, 2754–2763 (2019). https://doi.org/10.1007/s11665-019-04077-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04077-0