Abstract

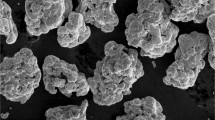

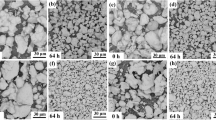

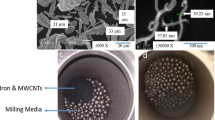

The effect of multiwall carbon nanotube (MWCNT) content on the physical and mechanical properties of Fe-MWCNT composites has been studied. High-energy ball milling (HEBM) is employed to produce the composite powder; following this, spark plasma sintering (SPS) process has been adopted for powder consolidation. The composite powder and the sintered products were subjected to structural characterization by XRD. Microstructural studies were carried out by optical, field-emission scanning and high-resolution transmission electron microscopy. While Fourier transform infrared spectroscopic study of composites was done to understand the bonding characteristics, Raman spectroscopy was employed to assess the structural damage of MWCNT after HEBM. The effects of processing on the behavior of C-C, C-O and Fe-O bonds are studied by x-ray photoelectron spectroscopy. Microhardness and compressive strength of composites are also determined. Finally, magnetic and electrical properties of the composites were characterized. It was observed that optimized ball milling conditions help to preserve the structural identity of MWCNT. Consolidation by SPS insured good interfacial bonding. The microhardness and compression strength are significantly improved in MWCNT-reinforced iron matrix composite. MWCNT has appreciably improved the electrical conductivity of the composites. Tethering of MWCNT by iron oxide has led to appreciable improvement in saturation magnetization till 3 wt.% MWCNT.

Similar content being viewed by others

References

S.R. Bakshi, D. Lahiri, and A. Agarwal, Carbon Nanotube Reinforced Metal Matrix Composites—A Review, Int. Mater. Rev., 2010, 55, p 41–64

J.Z. Liao, M.J. Tan, and I. Sridhar, Spark Plasma Sintered Multi-Wall Carbon Nanotube Reinforced Aluminum Matrix Composites, Mater. Des., 2010, 31, p 96–100

R.P. Bustamante, C.D.G. Esparza, I.E. Guel, M.M. Yoshida, L.L. Jiménez, A.S.P. García, and R.M. Sánchez, Microstructural and Mechanical Characterization of Al-MWCNT Composites Produced by Mechanical Milling, Mater. Sci. Eng. A, 2009, 502, p 159–163

A.M.K. Esawi, K. Morsi, A. Sayed, M. Taher, and S. Lanka, Effect of Carbon Nanotube (CNT) Content on the Mechanical Properties of CNT-Reinforced Aluminium Composites, Compos. Sci. Technol., 2010, 70, p 2237–2241

H. Kwon, D.H. Park, J.F. Silvain, and A. Kawasaki, Investigation of Carbon Nanotube Reinforced Aluminum Matrix Composite Materials, Compos. Sci. Technol., 2010, 70, p 546–550

C. Suryanarayana and N. Al, Aqeeli, Mechanically Alloyed Nanocomposites, Prog. Mater Sci., 2013, 58, p 383–512

A. Kumar, U. Pandel, and M.K. Banerjee, Effect of High Energy Ball Milling on the Structure of Iron—Multiwall Carbon Nanotubes (MWCNT) Composite, Adv. Mater. Res., 2017, 6, p 1–11

P. Sharma, A. Kumar, and M.K. Banerjee, Structural Evolution in Mechanically Alloyed and Spark Plasma Sintered Iron–0.15 wt.% MWCNT Composite, J. Mater. Eng. Perform., 2018, 27, p 4740–4748

F. Saba, S.A. Sajjadi, M.H. Sabzevar, and F. Zhang, Formation Mechanism of Nano Titanium Carbide on Multi-walled Carbon Nanotube and Influence of the Nano Carbides on the Load Bearing Contribution of the Nanotubes Inner-Walls in Aluminum Matrix Composites, Carbon, 2017, 115, p 720–729

J. Liao and M.J. Tan, Mixing of Carbon Nanotubes (CNTs) and Aluminum Powder for Powder Metallurgy Use, Powder Technol., 2011, 208, p 42–48

H. Li, J. Kang, C. He, N. Zhao, C. Liang, and B. Li, Mechanical Properties and Interfacial Analysis of Aluminum Matrix Composites Reinforced by Carbon Nanotubes with Diverse Structures, Mater. Sci. Eng. A, 2013, 577, p 120–124

H. Kwon, M. Takamichi, A. Kawasaki, and M. Leparoux, Investigation of the Interfacial Phases Formed Between Carbon Nanotubes and Aluminum in a Bulk material, Mater. Chem. Phys., 2013, 138, p 787–793

L. Ci, Z. Ryu, N. Yun, J. Phillipp, and M. Ruhle, Investigation of the Interfacial Reaction Between Multi-walled Carbon Nanotubes and Aluminum, Acta Mater., 2006, 54, p 5367–5375

W. Zhou, T. Yamaguchi, K. Kikuchi, N. Nomura, and A. Kawasaki, Effectively enhanced Load Transfer by Interfacial Reactions In Multi-Walled Carbon Nanotube Reinforced Al Matrix Composite, Acta Mater., 2017, 125, p 369–376

F. Housaer, F. Beclin, M. Touzin, D. Tingaud, A. Legris, and A. Addad, Interfacial Characterization in Carbon Nanotube Reinforced Aluminum Matrix Composites, Mater. Charact., 2015, 110, p 94–101

W. Zhou, S. Bang, H. Kurita, T. Miyazaki, Y. Fan, and A. Kawasaki, Interface and Interfacial Reactions in Multi-walled Carbon Nanotube Reinforced Aluminum Matrix Composites, Carbon, 2016, 96, p 919–928

S. Wang, R. Liang, B. Wang, and C. Zhang, Load-Transfer in Functionalized Carbon Nanotubes/Polymer Composites, Chem. Phys. Lett., 2008, 457, p 371–375

E.N. Konyushenko, J. Stejskal, T. Miroslava, J. Hradil, J. Kovářová, and J. Prokeš, Multiwall Carbon Nanotubes Coated With Polyaniline, Polymer, 2006, 47, p 5715–5723

A. Choudhury and P. Kar, Doping Effect of Carboxylic Acid Group Functionalized Multi-walled Carbon Nanotube on Polyaniline, Compos. B Eng., 2011, 42, p 1641–1647

C.O. Baker, X. Huang, W. Nelson, and R.B. Kaner, Polyaniline nanofibers: Broadening Applications for Conducting Polymers, Chem. Soc. Rev., 2017, 46, p 1510–1525

M.R. Basariya, V.C. Srivastava, and N.K. Mukhopadhyay, Microstructural Characteristics and Mechanical Properties of Carbon Nanotube Reinforced Aluminum Alloy Composites Produced by Ball Milling, Mater. Des., 2014, 64, p 542–549

K. Sarkar, S. Sarkar, and P.K. Das, Spark Plasma Sintered Multiwalled Carbon Nanotube/Silicon Carbide Composites: Densification, Microstructure, And Tribo-mechanical Characterization, J. Mater. Sci., 2016, 51, p 6697–6710

T. Varo and A. Canakci, Effect of the CNT Content on Microstructure, Physical and Mechanical Properties of Cu-Based Electrical Contact Materials Produced by Flake, Powder Metall., 2016, 40, p 2711–2720

M.T.Z. Hassan, A.M.K. Esawi, and S. Metwalli, Effect of Carbon Nanotube Damage on the Mechanical Properties Of Aluminium–Carbon Nanotube Composites, J. Alloys Compd., 2014, 607, p 215–222

J.G. Park, D.H. Keum, and Y.H. Lee, Strengthening Mechanisms in Carbon Nanotube-Reinforced Aluminum Composites, Carbon, 2015, 95, p 690–698

S.E. Shin, Y.J. Ko, and D.H. Bae, Mechanical and Thermal Properties of Nanocarbon-Reinforced Aluminum Matrix Composites at Elevated Temperatures, Compos. B, 2016, 106, p 66–73

S. Zhao, Z. Zheng, Z. Huang, S. Dong, P. Luo, Z. Zhang, and Y. Wang, Cu Matrix Composites Reinforced with Aligned Carbon Nanotubes: Mechanical, Electrical and Thermal Properties, Mater. Sci. Eng., 2016, 675, p 82–91

W. Zhou, T. Yamaguchi, K. Kikuchi, N. Nomura, and A. Kawasaki, Effectively Enhanced Load Transfer by Interfacial Reactions In Multi-Walled Carbon Nanotube Reinforced Al Matrix Composites, Acta Mater., 2017, 125, p 369–376

J.Y. Suh and D.H. Bae, Mechanical Properties of Fe-Based Composites Reinforced with Multi-Walled Carbon Nanotubes, Mater. Sci. Eng. A, 2013, 582, p 321–325

F.C. Wang, Z.-H. Zhang, Y.J. Sun, Y. Liu, Z.Y. Hu, H. Wang, A.V. Korznikov, E. Korznikova, Z.F. Liu, and S. Osamu, Rapid and Low Temperature Spark Plasma Sintering Synthesis of Novel Carbon Nanotube Reinforced Titanium Matrix Composites, Carbon, 2015, 95, p 396–407

K.S. Munira, Y. Zheng, D. Zhang, J. Lind, Y. Lia, and C. Wena, Microstructure and Mechanical Properties of Carbon Nanotubes Reinforced Titanium Matrix Composites Fabricated Via Spark Plasma Sintering, Mater. Sci. Eng. A, 2017, 688, p 505–523

A. Kumar, M.K. Banerjee, and U. Pandel, Development of a Novel MWCNT Reinforced Iron Matrix Nanocomposite Through Powder Metallurgy Route, Powder Technol., 2018, 331, p 41–51

B. Ghosh and S.K. Pradhan, Microstructure Characterization of Nanocrystalline Fe3C Synthesized by High-Energy Ball Milling, J. Alloys Compd., 2009, 477, p 127–132

O. Drbohlav and A.R. Yavari, Magnetic Properties of Mechanically Alloyed Nanocrystalline fcc Cu50Fe50 During Thermal Decomposition, J. Magn. Mater., 1994, 137, p 243–248

O. Drbohlav and A.R. Yavari, Mechanical Alloying and Thermal Decomposition of Ferromagnetic Nanocrystalline f.c.c.-Cu50Fe50, Acta Mater., 1995, 43, p 1799–1809

E. Dislaki, J. Sorta, and E. Pellicer, Parametric Aqueous Electro Deposition Study and Characterization of Fe–Cu Films, Electrochem. Acta, 2017, 231, p 739–748

P. Gorria, D. Martínez-Blanco, J.A. Blanco, A. Hernando, J.S. Garitaonandia, L.F. Barquín, J. Campo, and R.I. Smith, Invar Effect in fcc-FeCu Solid Solutions, Phys. Rev. B, 2004, 69, p 214421–214425

C. Cutrano and Ch.E. Lekka, Structural, Magnetic and Electronic Properties of Cu-Fenanoclusters by Density Functional Theory Calculations, J. Alloys Compd., 2017, 707, p p114–p119

T. Sourmail, Near Equiatomic Fe Co Alloys: Constitution, Mechanical and Magnetic Properties, Prog. Mater Sci., 2005, 50, p 816–880

H. Jeon, J. Kim, J.Y. Chung, and Y.D. Kim, Formation of Nanocrystalline Fe–Co Powders Produced by Mechanical Alloying, Mater. Sci. Eng. A, 2000, 291, p 17–21

B.H. Lee, B.S. Ahn, D.G. Kim, S. Tag Oh, H. Jeon, J. Ahn, and Y.D. Kim, Microstructure and Magnetic Properties of Nanosized Fe–Co Alloy Powders Synthesized by Mechano-Chemical and Mechanical Alloying Process, Mater. Lett., 2003, 57, p 1103–1107

C. Kuhrt and L. Schultz, Formation and Magnetic Properties of Nanocrystalline Mechanically Alloyed Fe–Co and Fe–Ni, J. Appl. Phys., 1993, 73, p 6588–6590

H. Shokrollahi, The Magnetic and Structural Properties of the Most Important Alloys of Iron Produced by Mechanical Alloying, Mater. Des., 2009, 30, p 3374–3387

A. Zelenakova, D. Oleksakova, J. Degmova, J. Kovac, P. KollaR, M. Kusy, and P. Sovak, Structural and Magnetic Properties of Mechanically Alloyed FeCo Powders, J. Magn. Magn. Mater., 2007, 316, p 519–522

X. Sun, A. Gutierrez, M.J. Yacaman, X. Dong, and S. Jin, Investigations on Magnetic Properties and Structure for Carbon Encapsulated Nanoparticles of Fe, Co, Ni, Mater. Sci. Eng. A, 2000, 286, p 157–160

J. Ma, M. Qin, X. Zhang, L. Zhang, X. Qu, and L. Tian, Microstructure and Magnetic Properties of High Density P/M Pure Iron, Mater. Res. Bull., 2015, 64, p 123–127

T.T. Bui, X.Q. Le, D.P. To, and V.T. Nguyen, Investigation of Typical Properties on Nanocrystalline Iron Powders Prepared by Ball Milling Techniques, Adv. Nat. Sci. Nanosci. Nanotechnol., 2013, 4, p 045003–045008

F.C. Dillon, A. Bajpai, A. Koos, S. Downes, Z. Aslam, and N. Grobert, Tuning the Magnetic Properties of Iron-Filled Carbon Nanotubes, Carbon, 2012, 50, p 3674–3681

F.S. Boi, G. Mountjoy, R.M. Wilson, Z. Luklinska, L.J. Sawiak, and M. Baxendale, Multiwall Carbon Nanotubes Continuously Filled With Micrometer-Length Ferromagnetic a-Fe Nanowires, Carbon, 2013, 64, p 351–358

H. Kim and W. Sigmund, Iron Particles in Carbon Nanotubes, Carbon, 2005, 43, p 1743–1748

H. Raanaei, H. Eskandari, and V.M. Hosseini, Structural and Magnetic Properties of Nanocrystalline Fe–Co–Ni Alloy Processed by Mechanical Alloying, J. Magn. Magn. Mater., 2016, 398, p 190–195

O. Boshko, O. Nakonechna, N. Belyavina, M. Dashevskyi, and S. Revo, Nanocrystalline Fe–C comPosites Obtained by Mechanical Alloying of Iron and Carbon nanotubes, Adv. Powder Technol., 2017, 28, p 964–972

K.T. Kim, J. Ecket, G. Liu, M.P. Jin, K.L. Byung, and H.H. Soon, Influence of Embedded-Carbon Nanotubes on the Thermal Properties of Copper Matrix Nanocomposite Processed by Molecular-Level Mixing, Scipta Mater., 2011, 64, p 181–184

N. Nayana, A.K. Shukla, P. Chandranb, S.R. Bakshib, S.V.S.N. Murtyb, B. Pantb, and P.V. Venkitakrishnanb, Processing and Characterization of Spark Plasma Sintered Copper/Carbon Nanotube Composites, Mater. Sci. Eng. A, 2017, 682, p 229–237

H.S. Avener, Introduction to Physical Metallurgy, Vol 35, Mc Graw Hill Eduction, New Delhi, 2013

Z.Y. Liu, S.J. Xu, B.L. Xiao, P. Xue, W.G. Wang, and Z.Y. Ma, Effect of Ball-Milling Time on Mechanical Properties of Carbon Nanotubes Reinforced Aluminum Matrix Composites, Compos. A, 2012, 43, p 2161–2168

K.S. Munir, M. Qian, Y. Li, D.T. Oldfield, P. Kingshott, M. De, and C.Wen Zhuand, Quantitative Analyses of MWCNT-Ti Powder Mixtures using Raman Spectroscopy: The Influence of Milling Parameters on Nanostructural Evolution, Adv. Eng. Mater., 2015, 17, p 1660–1669

S. Wanga, R. Liang, B. Wang, and C. Zhang, Dispersion and Thermal Conductivity of Carbon Nanotube Composites, Carbon, 2009, 47, p 53–57

Z.Y. Liu, B.L. Xiao, W.G. Wang, and Z.Y. Ma, Developing High-Performance Aluminum Matrix Composites with Directionally Aligned Carbon Nanotubes by Combining Friction Stir Processing and Subsequent Rolling, Carbon, 2013, 62, p 35–42

H. Kwon, D.H. Park, J.F. Silvain, and A. Kawasak, Investigation of Carbon Nanotube Reinforced Aluminum Matrix Composite Materials, Compos. Sci. Technol., 2010, 70, p 546–550

C.L. Xu, B.Q. Wei, R.Z. Ma, J. Liang, X.K. Ma, and D.H. Wu, Fabrication of aluminum–Carbon Nanotube Composites and Their Electrical Properties, Carbon, 1999, 37, p 855–858

S.E. Shin, H.J. Choi, and D.H. Bae, Electrical and Thermal Conductivities of Aluminum-Based Composites Containing Multi-walled Carbon Nanotubes, J. Compos. Mater., 2013, 47, p 2249–2256

G. Tong, W. Wa, Q. Hua, Y. Miao, J. Guan, and H. Qian, Enhanced Electromagnetic Characteristics of Carbon Nanotubes/Carbonyl Iron Powders Complex Absorbers in 2–18GHz Ranges, J. Alloys Compd., 2011, 509, p 451–456

S. Hudziak, A. Darfeuille, R. Zhang, T. Peijs, G. Mountjoy, G. Bertoni, and M. Baxendale, Magnetoresistive Phenomena on Fe-Filled Carbon Nanotube/Elastomer Composites, Nanotechnology, 2010, 21, p 125505–125508

B. Ma, Y. Huang, C. Zhu, C. Chen, M. Fan, and D. Sun, A Facile Method to Synthesize Carbon Coated Fe, Co and Ni and an Examination of Their Magnetic Properties, J. Alloy. Compd., 2016, 687, p 74–745

H. Raanaei, H. Eskandari, and V.M. Hosseini, Structural and Magnetic Properties of Nano Crystalline Fe–Co–Ni Alloy Processed by Mechanical Alloying, J. Magnetism & Magnetic Materials, 2016, 398, p 190–195

O. Boshko, O. Nakonechna, M. Dashevskyi, K. Lvanenko, N. Belyavina, and S. Revo, Effect of the Carbon Nanotubes on Structure and Magnetic Properties of the Fe-Cu(4:1) Composites, Adv. Powder Technol., 2016, 27, p 1101–1108

B. Hea, M. Wang, W. Sunc, and Z. Shen, Preparation and Magnetic Property of the MWNT-Fe2+ Composite, Mater. Chem. Phys., 2006, 95, p 289–293

Acknowledgments

The authors are thankful to the Materials Research Centre, Malaviya National Institute of Technology, Jaipur, India, for providing the characterization facilities. The authors also thank Mr. M. Shiva Kumar, Indian Institute of Technology, Kanpur, India, for his kind help in VSM experiments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, A., Banerjee, U., Chowrasia, M.K. et al. Effect of MWCNT Content on the Structure and Properties of Spark Plasma-Sintered Iron-MWCNT Composites Synthesized by High-Energy Ball Milling. J. of Materi Eng and Perform 28, 2983–3000 (2019). https://doi.org/10.1007/s11665-019-04056-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04056-5