Abstract

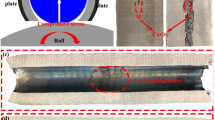

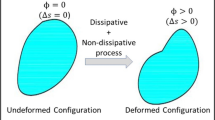

Numerical simulation based on extended finite element method was employed to investigate the fatigue crack propagation of nickel-based superalloy at room temperature. Experimental tests on compact tension specimens have performed to obtain fatigue crack propagation parameters in Paris region. The extended finite element method has presented a new approach to solve the stress intensity factors and can effectively predict crack propagation without re-meshing at crack tip. The simulation results are in good accordance with experimental data in real 3D cases.

Similar content being viewed by others

References

N. Makuch and M. Kulka, Fracture Toughness of Hard Ceramic Phases Produced on Nimonic 80A-Alloy by Gas Boriding, Ceram. Int., 2016, 42((2, Part B)), p 3275–3289

K. Tokaji, S. Takafuji, K. Ohya, Y. Kato, and K. Mori, Fatigue Behaviour of Beta Ti-22V-4Al Alloy Subjected to Surface-Microstructural Modification, Journal of Materials Science, 2003, 38(6), p 1153–1159

K.-B. Shiozawa, Y. Tohda, and S.M. Sun, Crack Initiation and Small Fatigue Crack Growth Behaviour of Squeeze-Cast Al-Si Aluminium Alloys, Fatigue Fract. Eng. Mater. Struct., 1997, 20(2), p 237–247

S.M. Beden, S. Abdullah, and A.K. Ariffin, Review of Fatigue Crack Propagation Models for Metallic Components, Eur. J. Sci. Res., 2009, 28(3), p 364–397

P. Paris and F. Erdogan, A Critical Analysis of Crack Propagation Laws, J. Basic Eng., 1963, 85(4), p 528–533

Y. Murakami, Stress Intensity Factors Handbook, Pergamon Press, Oxford, 1987

T.L. Anderso, Fracture Mechanics: Fundamentals and Applications, CRC Press, Boca Raton, 2005

J.R. Rice, A Path Independent Integral and the Approximate Analysis of Strain Concentration by Notches and Cracks, J. Appl. Mech., 1968, 35(2), p 379–386

C.F. Shih and R.J. Asaro, Elastic-Plastic Analysis of Cracks on Bimaterial Interfaces: Part I—Small Scale Yielding, J. Appl. Mech., 1988, 55(2), p 299–316

S. Liu, C. Liu, Y. Hu, S. Gao, Y. Wang, and H. Zhang, Fatigue Life Assessment of Centrifugal Compressor Impeller Based on FEA, Eng. Fail. Anal., 2016, 60, p 383–390

V. Chaves, C. Madrigal, and A. Navarro, Fatigue Limit Predictions at Stress Concentrations Using FEA and Microstructural Fracture Mechanics, Theor. Appl. Fract. Mech., 2017, 87, p 11–20

P. Zerres and M. Vormwald, Finite Element Based Simulation of Fatigue Crack Growth with a Focus on Elastic-Plastic Material Behavior, Comput. Mater. Sci., 2012, 57, p 73–79

H. Pathak, A. Singh, and I.V. Singh, Fatigue Crack Growth Simulations of 3-D Problems Using XFEM, Int. J. Mech. Sci., 2013, 76, p 112–131

T. Belytschko and T. Black, Elastic Crack Growth in Finite Elements with Minimal Remeshing, Int. J. Numer. Meth. Eng., 1999, 45(5), p 601–620

M.L. Benzeggagh and M. Kenane, Measurement of Mixed-Mode Delamination Fracture Toughness of Unidirectional Glass/Epoxy Composites with Mixed-Mode Bending Apparatus, Compos. Sci. Technol., 1996, 56(4), p 439–449

B. Wang, H. De Backer, and A. Chen, An XFEM Based Uncertainty Study on Crack Growth in Welded Joints with Defects, Theor. Appl. Fract. Mech., 2016, 86, Part B, p 125–142

S. Bhattacharya and K. Sharma, Fatigue Crack Growth Simulations of FGM Plate under Cyclic Thermal Load by XFEM, Proc. Eng., 2014, 86(Supplement C), p 727–731

H. Pathak, A. Singh, and I.V. Singh, Fatigue Crack Growth Simulations of 3-D Problems Using XFEM, Int. J. Mech. Sci., 2013, 76(11), p 112–131

P.A. Wawrzynek and A.R. Ingraffea, Interactive Finite Element Analysis of Fracture Processes: An Integrated Approach, Theor. Appl. Fract. Mech., 1987, 8(2), p 137–150.

H. Zhang, C. Huang, Z. Guan, J. Li, Y. Liu, R. Chen, and Q. Wang, Effects of the Electron Beam Welding Process on the Microstructure, Tensile, Fatigue and Fracture Properties of Nickel Alloy Nimonic 80A, J. Mater. Eng. Perform., 2018, 27(1), p 89–98

ASTM, “Standard Test Method for Measurement of Fatigue Crack Growth Rates,” ASTM E647-2013a, 2013

S. Mohammadi, Extended Finite Element Method for Fracture Analysis of Structures, Blackwell Publishing, New York, 2008

P. Elisa, Virtual Crack Closure Technique and Finite Element Method for Predicting the Delamination Growth Initiation in Composite Structures, Advances in Composite Materials-Analysis of Natural and Man-Made Materialsed, InTech, 2011

A. Bergara, J.I. Dorado, A. Martin-Meizoso, and J.M. Martínez-Esnaola, Fatigue Crack Propagation in Complex Stress Fields: Experiments and Numerical Simulations Using the Extended Finite Element Method (XFEM), Int. J. Fatigue, 2017, 103(Supplement C), p 112–121

V. Tvergaard, On Fatigue Crack Growth in Ductile Materials by Crack–Tip Blunting, J. Mech. Phys. Solids, 2004, 52(9), p 2149–2166

K.A. Rozman, J.J. Kruzic, and J.A. Hawk, Fatigue Crack Growth Behavior of Nickel-Base Superalloy Haynes 282 at 550–750 °C, J. Mater. Eng. Perform., 2015, 24(8), p 2841–2846

F. Farukh, L. Zhao, R. Jiang, P. Reed, D. Proprentner, and B. Shollock, Fatigue Crack Growth in a Nickel-Based Superalloy at Elevated Temperature—Experimental Studies, Viscoplasticity Modelling and XFEM Predictions, Mechanics of Advanced Materials & Modern Processes, 2015, 1(1), p 2

Acknowledgments

This work was supported by the National Natural Science Research Foundation of China (Nos. 11327801, 11502151, 11572057), the Program for Changjiang Scholars and Innovative Research Team (No. IRT14R37), and Key Science and Technology Support Program of Sichuan Province (No. 2015JPT0001).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhang, H., Li, P., Wang, Q. et al. Fatigue Crack Propagation of Nickel-Based Superalloy: Experiments and Simulations with Extended Finite Element Method. J. of Materi Eng and Perform 28, 967–972 (2019). https://doi.org/10.1007/s11665-018-3818-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3818-4