Abstract

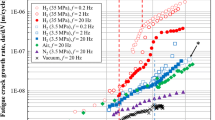

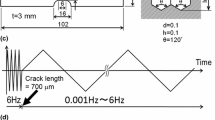

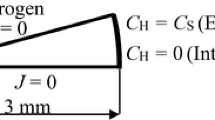

A new method of nanohardness distribution for investigating the hydrogen effect on the fatigue crack in austenitic stainless steels was developed. The nanohardness distribution around the fatigue crack tip is dependent on the plastic zone and different microstructures in materials. Nanoindentation could provide a possibility to quantitatively estimate the size of the plastic zone and to expressly identify the strain-induced α′ martensitic transformation around the fatigue crack tip. The results of measured nanohardness distribution reveal that hydrogen reduces the size of the estimated plastic zone around the fatigue crack tip, especially in the specimen tested in hydrogen gas environment, which is attributed to hydrogen-enhanced localized plasticity. Both hydrogen and α′ martensite greatly influence the nanohardness and the gradient of hydrogen concentration near the crack tip, which will have a significant effect on the fatigue crack growth.

Similar content being viewed by others

References

L. Zhang, Z.Y. Li, J. Zheng, Y.Z. Zhao, P. Xu, C.L. Zhou, C.S. Zhou, and X.Y. Chen, Dependence of Hydrogen Embrittlement on Hydrogen in the Surface Layer in Type 304 Stainless Steel, Int. J. Hydrog. Energy, 2014, 39, p 20578–20584

R. Liu, N. Narita, H. Birnbaum, and E.N. Pugh, Studies of the Orientations of Fracture Surfaces Produced in Austenitic Stainless Steels by Stress-corrosion Cracking and Hydrogen Embrittlement, Metall. Trans. A, 1980, 11, p 1563–1574

T. Michler and J. Naumann, Hydrogen Environment Embrittlement of Austenitic Stainless Steels at Low Temperature, Int. J. Hydrog. Energy, 2008, 33, p 2111–2122

G. Han, J. He, S. Fukuyama, and K. Yokogawa, Effect of Stain Induced Martensite on Hydrogen Environment Embrittlement of Sensitized Austenitic Stainless Steels at Low Temperatures, Acta Mater., 1998, 46, p 4559–4570

W. Dietzel, The Use of Crack-Tip Opening Displacement for Testing of the Hydrogen Embrittlement of High-Strength Steels, J. Mater. Eng. Perform., 2004, 40, p 749–755

D.M. Dennj, D. Cagan, Z. Ning, and O. Erkan, Modelling of Stress-corrosion Cracking by Using Peridynamics, Int. J. Hydrog. Energy, 2016, 41, p 6593–6609

M. Yukitaka and M. Saburo, Effect of Hydrogen on Fatigue Crack Growth of Metals, Eng. Fract. Mech., 2010, 77, p 1926–1940

J. Yamabe, M. Yoshikawa, H. Matsunaga, and S. Matsuoka, Effects of Hydrogen Pressure, Test Frequency and Test Temperature on Fatigue Crack Growth Properties of Low-carbon Steel in Gaseous Hydrogen, Proc. Struct. Int., 2016, 2, p 525–532

S.P. Lynch, Environmentally Assisted Cracking: Overview of Evidence for an Adsorption-induced Localised-slip Process, Acta Metall., 1988, 36, p 2639–2661

K.A. Nibur, D.F. Bahr, and B.P. Somerday, Hydrogen Effects on Dislocation Activity in Austenitic Stainless Steel, Acta Mater., 2006, 54, p 2677–2684

Y.J. Hong, C.S. Zhou, Y.Y. Zheng, L. Zhang, J.Y.Z.B. An, X.Y. Chen, and X.H. Wang, Hydrogen Effect on the Deformation Evolution Process in Situ Detected by Nanoindentation Continuous Stiffness Measurement, Mater. Charact., 2017, 127, p p35–40

B.W. Choi, D.H. Seo, and J. Jang, A Nanoindentation Study on the Micromechanical Characteristics of API, X1000 Pipeline Steel, J. Mater. Eng. Perform., 2009, 15, p 373

T.M. Wilkinsona, D. Wu, M.A. Musselmana, N. Li, N. Mara, and C.E. Packard, Mechanical Behavior of Rare-earth Orthophosphates Near the Monazite/Xenotime Boundary Characterized by Nanoindentation, Mater. Sci. Eng. A, 2017, 691, p 203–210

Y. Katz, N. Tymiak, and W.W. Gerberich, Nanomechanical Probes as New Approaches to Hydrogen/Deformation Interaction Studies, Eng. Fract. Mech., 2001, 68, p 619–646

L. Zhang, B. An, S. Fukuyama, and K. Yokogawa, Hydrogen Effects on Localized Plasticity in SUS310S Stainless Steel Investigated by Nanoindentation and Atomic Force microscopy, Jpn. J. Appl. Phys., 2009, 48(8), p 1–4

A. Barnoush and H. Vehoff, In Situ Electrochemical Nanoindentation: a Technique for Local Examination of Hydrogen Embrittlement, Corros. Sci., 2008, 50, p 259–267

Y. Mine, K. Doi, S. Matsuoka, and Y. Murakami, The Influences of Hydrogen on Microscopic Plastic Deformation Behavior of SUS304 and SUS316L Stainless Steels, J. Soc. Mater. Sci. Jpn., 2008, 57, p 255–261

T.P. Perng and C.J. Altstetter, Effects of Deformation on Hydrogen Permeation in Austenitic Stainless Steels, Acta. Metall., 1986, 34, p 1771–1781

M. Dadfarnia, P. Sofronis, and T. Neeraj, Hydrogen Interaction with Multiple Traps: Can It Be Used to Mitigate Embrittlement?, Int. J. Hydrogen Energy, 2011, 36, p 10141–10148

A.J. McEvily and J.L.G. Velazquez, Fatigue Crack Tip Deformation Process as Influenced by the Environment, Metall. Trans., 1992, 23, p 1992–2001

Y. Murakami, T. Kanezaki, and Y.J. Mine, Hydrogen Effect Against Hydrogen Embrittlement, Metall. Mater. Trans., 2010, 21, p 2548–2562

T.C. Chen, S.T. Chen, and L.W. Tsay, The Role of Induced α′ Martensite on the Hydrogen - Assisted Fatigue Crack Growth of Austenitic Stainless Steels, Int. J. Hydrog. Energy, 2014, 39, p 10293–10302

T.P. Perng and C.J. Altstetter, Effects of Deformation on Hydrogen Permeation in Austenitic Stainless Steels, Acta Metall., 1986, 34, p 1771–1781

X.K. Sun, J. Xu, and Y.Y. Li, Hydrogen Permeation Behavior in Metastable Austenitic Stainless Steels 321 and 304, Acta Metall., 1989, 37, p 2171–2176

H. Uyama, M. Nakashima, K. Morishige, Y. Mine, and Y. Murakami, Effects of Hydrogen Charge on Microscopic Fatigue Behavior of Annealed Carbon Steels, Fatigue Fract. Eng. Mater. Struct., 2006, 29, p 1066–1074

P. Sofronis and R. Mcmeeking, Numerical Analysis of Hydrogen Transport Near a Blunting Crack Tip, J. Mech. Phys. Solid, 1989, 37, p 317–350

X.H. An, S.D. Wu, Z.F. Zhang, R.B. Figueiredo, N. Gao, and T.G. Langdon, Enhanced Strength-ductility Synergy in Nanostructured Cu and Cu-Al Alloys Processed by High-pressure Torsion and Subsequent Annealing, Scripta Mater., 2012, 66, p 227–230

L. Lu, R. Schwaiger, Z.W. Shan, M. Dao, K. Lu, and S. Suresh, Nano-sized Twins Induce High Rate Sensitivity of Flow Stress in Pure Copper, Acta Mater., 2005, 53, p 2169–2179

P. Zhang, S.X. Li, and Z.F. Zhang, General Relationship Between Strength and Hardness, Mater. Sci. Eng. A, 2011, 529, p 62–73

W.C. Oliver and G.M. Pharr, An Improved Technique for Determining Hardness and Elastic-modulus Using Load and Displacement Sensing Indentation Experiments, J. Mater. Res., 1992, 7, p 1564–1583

Acknowledgments

This research was supported by the National Key Basic Research Program of China (973 Program, Grant No. 2015CB057601), the National Natural Science Foundation of China (51571181, 51401181), and the Zhejiang Provincial Natural Science Foundation of China (LY15E010006, LQ14E010003).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Tao, H., Hong, Y., Chen, X. et al. Hydrogen Effect on the Fatigue Crack Growth in Austenitic Stainless Steel Investigated by a New Method Based on Nanohardness Distribution. J. of Materi Eng and Perform 27, 6485–6492 (2018). https://doi.org/10.1007/s11665-018-3764-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3764-1