Abstract

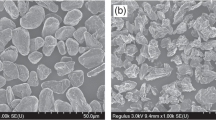

With higher power, frequency and longer life of microwave tubes, cathode heater assembly is being modified to enhance the warm-up performance and reliability, which are governed by ceramics thermal conductivity, electrical resistivity and shrinkage. In present work, a potting material with a high thermal conductivity of 22.14 W/(m K) and low linear shrinkage of 5.5% was prepared using two kinds of alumina powders with different size and morphology. Aqueous slurries were produced for centrifugal casting. The highest solid loading slurries with 70 vol.% were obtained. Green body with relative density above 70% was easily made from slurries using centrifugal casting. Relative sintered density reached 86.75% maximum without any sintering aids. Rheological behavior of slurries, potting microstructure, sintering shrinkage and thermal conductivity were analyzed. Continuous particle distribution, series and parallel models were used to guide the powders proportion and explain the thermal conductivity. The potting material thermal conductivity experimental data agreed with the series and parallel models when the weight parameter ξ was between 0.3 and 0.5.

Similar content being viewed by others

References

D.S. Orlowska, Fast warm cathode—practical fielded design, in National Vacuum Electronics Conference (Surrey Ion Beam Centre, 2007)

K.S. Pal, S. Ghosh, N. Dandapat, S. Datta, D. Basu, and R.S. Raju, Development of Suitable Potting Material for Dispenser Cathodes of a High Power Microwave Tube, Mater. Sci. Eng. B, 2012, 177(2), p 228–232

P. Swartzentruber, M. Collier, R. Dewees, and W. Epperson, Alternative ceramic potting materials for dispenser cathodes, in Vacuum Electronics Conference (2012), pp. 483–484

C.W. Park and D.Y. Yoon, Effect of SiO2, CaO2 and MgO Addition on the Grain Growth of Alumina, J. Am. Ceram. Soc., 2000, 83(10), p 2605–2609

L. Wolverton, J.O. Tarter, R.E. Eitel, and M. Weisenberger, P1–33: Thermal properties of alumina cathode heater potting materials, in Vacuum Electronics Conference (IVEC), (2010), p. 165

L.R. Falce, Dispenser cathodes: The current state of the technology, in International Electron Devices Meeting (1983), pp. 448–451

G.L. Messing and G.Y. Onoda, Inhomogeneity-Packing Density Relations in Binary Powders—Experimental Studies, J. Am. Ceram. Soc., 1978, 61(7–8), p 363–366

J.A. Dodds, The Porosity and Contact Points in Multicomponent Random Sphere Packings Calculated by a Simple Statistical Geometric Model, J. Colloid Interface Sci., 1980, 77(2), p 317–327

J. Funk and D. Dinger, Packing of Discrete Versus Continuous Particle Size Distributions, Interceramic, 1992, 41(5), p 332–334

J. Funk and D. Dinger, Fundamentals of Particle Packing, Monodisperse Spheres, Interceramic, 1992, 41(1), p 10–14

J. Funk and D. Dinger, Review of Packing in Polydisperse Particle Systems, Interceramic, 1992, 41(2), p 95–97

J. Funk and D. Dinger, Computer Modelling of Particle Packing Phenomena, Interceramic, 1993, 42(3), p 150–153

J. Zheng, W.B. Carlson, and J.S. Reed, The Packing Density of Binary Powder Mixtures, J. Eur. Ceram. Soc., 1995, 15(5), p 479–483

K.R. McGeary, Mechanical Packing of Spherical Particles, J. Am. Ceram. Soc., 1961, 44(10), p 513–522

A.B. Yu, N. Standish, and A. Mclean, Porosity Calculation of Binary Mixtures of Nonspherical Particles, J. Am. Ceram. Soc., 1993, 76(11), p 2813–2816

P.A. Smith and R.A. Haber, Effect of Particle Packing on the Filtration and Rheology Behavior of Extended Size Distribution Alumina Suspensions, J. Am. Ceram. Soc., 1995, 78(7), p 1737–1744

S. Taruta, N. Takusagawa, K. Okada, N. Otsuka, S. Taruta, N. Takusagawa, K. Okada, and N. Otsuka, Slip Casting of Alumina Powder Mixtures with Bimodal Size Distribution, J. Ceram. Soc. Jpn., 1996, 104(1209), p 447–450

G.T. Igrave, J.M.F. Ferreira, A.T. Fonseca, and O. Lyckfeldt, Influence of Particle Size Distribution on Colloidal Processing of Alumina, J. Eur. Ceram. Soc., 1998, 18(3), p 249–253

J.M.F. Ferreira and H.M.M. Diz, Pressure Slip Casting of Bimodal Silicon Carbide Powder Suspensions, Ceram. Int., 1999, 25(6), p 491–495

G. Tari, J.M.F. Ferreira, and A.T. Fonseca, Influence of Particle Size and Particle Size Distribution On Drying-Shrinkage Behaviour of Alumina Slip Cast Bodies, Ceram. Int., 1999, 25(6), p 577–580

S. Taruta, Y. Sakurai, N. Takusagawa, K. Okada, and N. Otsuka, Slip Casting of Alumina Powder Mixtures with Bimodal Size Distribution: Influence of Particle Size Difference Between Fine and Coarse Powders on Packing and Consolidation Process, J. Ceram. Soc. Jpn., 2000, 108, p 254–260

J.U. Chenhui, W. Yanmin, Y.E. Jiandong, L.I. Xinheng, W. Yanmin, Y.E. Jiandong, and L.I. Xinheng, Effect of Particle Size Distribution on the Rheological Behavior of Dense Alumina Suspensions, J. Chin. Ceram. Soc., 2006, 34(8), p 985–991 (in Chinese)

W. Qi, C. Wei, G. Yiyao, and X. Zhipeng, Preparation and Sintering Properties of Alumina Slurries with High Solid Loading, Rare Metal Mat. Eng., 2013, 42(S1), p 400–403 (in Chinese)

Y. Sun, S. Shimai, X. Peng, M. Dong, H. Kamiya, and S. Wang, A Method for Gelcasting High-Strength Alumina Ceramics with Low Shrinkage, J. Mater. Res., 2014, 29(02), p 247–251

A. Heunisch, A. Dellert, and A. Roosen, Effect of Powder, Binder and Process Parameters on Anisotropic Shrinkage in Tape Cast Ceramic Products, J. Eur. Ceram. Soc., 2010, 30(16), p 3397–3406

Z. Fu, P. Polfer, T. Kraft, and A. Roosen, Correlation Between Anisotropic Green Microstructure of Spherical-Shaped Alumina Particles and Their Shrinkage Behavior, J. Am. Ceram. Soc., 2015, 98(11), p 3438–3444

G. Tarì, J.M.F. Ferreira, A.T. Fonseca, and O. Lyckfeldt, Influence of Particle Size Distribution on Colloidal Processing of Alumina, J. Eur. Ceram. Soc., 1998, 18(3), p 249–253

A. Tsetsekou, C. Agrafiotis, and A. Milias, Optimization of the Rheological Properties of Alumina Slurries for Ceramic Processing Applications Part I: Slip-Casting, J. Eur. Ceram. Soc., 2001, 21(3), p 363–373

R.G. Horn, Surface Forces and Their Action in Ceramic Materials, J. Am. Ceram. Soc., 1990, 73(5), p 1117–1135

C.J. Brinker and G.W. Scherer, Sol–Gel Science, Academic press, Boston, 1990

S.J. Schneider, Engineered Materials Handbook, ASM International, Geauga, 1991

E. Carlström, Surface and Colloid Chemistry in Ceramics: An Overview, Marcel Dekker, New York, 1994

R. Moreno, The Role of Slip Additives in Tape Casting Technology 2. Binders and Plasticizers, Am. Ceram. Soc. Bull., 1992, 71(11), p 1647

L. Miettinen, P. Kekäläinen, T. Turpeinen, J. Hyväluoma, J. Merikoski, and J. Timonen, Dependence of Thermal Conductivity on Structural Parameters in Porous Samples, AIP Adv., 2012, 2(1), p 2150–2240

A.G. Leach, The Thermal Conductivity of Foams. I. Models for Heat Conduction, J. Phys. D Appl. Phys., 1999, 26(5), p 733

Z. Hashin and S. Shtrikman, A Variational Approach to the THEory of The Effective Magnetic Permeability of Multiphase Materials, J. Appl. Phys., 1962, 33(10), p 3125–3131

R. Landauer, The Electrical Resistance of Binary Metallic Mixtures, J. Appl. Phys., 1952, 23(7), p 779–784

L. Gong, Y. Wang, X. Cheng, R. Zhang, and H. Zhang, A Novel Effective Medium Theory for Modelling the Thermal Conductivity of Porous Materials, Int. J. Heat Mass Transfer, 2014, 68(1), p 295–298

H. Shenker, J.I. Lauritzen, R.J. Corruccini, and S.T. Lonberger, Reference Tables for Thermocouples, 564 (1955)

Acknowledgments

This work was supported by the State Key Lab of Advanced Metals and Materials (Grant No. 2018-Z06). AV acknowledges support from the National Science Foundation (IRES 1358088).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, X., Hao, J., Guo, Z. et al. The Improved Thermal Conductivity of a Potting Material for High-Power Fast Warm-Up Cathodes. J. of Materi Eng and Perform 27, 6701–6708 (2018). https://doi.org/10.1007/s11665-018-3760-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3760-5