Abstract

Computer modeling using a commercially available software package was used to explore the optimization of filling systems based on the relatively new concepts of avoiding entrainment of air bubbles and oxides by avoiding surface turbulence. The test casting was based on a pattern for a traditional top poured test bar, whose cross section was a tri-lobed clover-like shape. The study illustrates clearly that the detailed design of the filling system has a major influence on the conditions for defect generation during filling. Traditional steel casting systems using the widely popular assembly of preformed refractory tubes were found to behave poorly. Systems were demonstrated which were capable of delivering highly controlled filling behavior. The latest systems to be developed employed (1) a naturally pressurized filling system and (2) the use of filters placed flush on the top of the runner to act as bubble diverters, together with (3) terminal spin traps. These novel filling systems demonstrated excellent performance in simulation, in agreement with practical experience of the capability (of the trident gate in particular) to produce, for the first time in the history of casting, defect-free castings on a routine basis.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Modern foundry engineering is a well-developed and sophisticated industry utilizing cutting-edge technologies and tools including 3D printing, robots and automated manufacturing. Despite this, the most important production technology remains the use of greensand molds poured with cast iron or steel (Ref 1,2,3). This traditional technology is widespread because of its low cost and adequate quality. However, the quality requirements are continuously growing. It is recently becoming common for the customer to specify a requirement to pass the stringent dye penetrant test. This inspection technique illustrates the inadequacies of many current filling system designs (Ref 4,5,6,7), since the presence of surface-breaking oxide bifilms, cracks and bubbles is now clearly revealed.

Turbulence during the pouring of metals generates two main defects: (1) entrained air bubbles and (2) entrained oxide films from the surface of the liquid metal. The oxides are always entrained with the dry top surface of the oxide folded over against itself. This unbonded double interface (a ‘bifilm’) acts as a crack in the liquid metal, leading to the initiation of cracks and hot tears in the casting.

It is surprising how many of our common casting defects are the fault of entrained oxides and bubbles. For instance in the case of ‘gas porosity,’ pores up to about 5 mm diameter are the result of entrained air bubbles, whereas finer bubbles are usually bifilms inflated by gases in solution, often hydrogen. All cracks and hot tears appear to be the product of entrained bifilms. Sand inclusions are a reliable sign of turbulence; the air displaced backwards and forwards through the mold wall oxidizes away the sand binder. Once the sand is unbonded, it can be pulled away from the mold wall, penetrating the surface of the liquid metal via the surface oxide film. The result is that sand inclusions are usually found to be wrapped in their oxide ‘paper bag’ from the entrainment event. [Campbell records that he has never known sand inclusions to result from ‘poor sand’ quality (Ref 8)].

In general, providing they do not lead to cracks, the presence of bifilms in steels does not contribute to the rejection or scrapping of the casting because the population of these defects is usually invisible. However, properties, particularly toughness and fatigue, are reduced. It seems that bifilms are sufficiently small and compacted during turbulence that a high proportion can pass straight through a ceramic foam filter. For instance a 20 ppi (pores per inch) filter gives a pore diameter of approximately 1 mm, allowing a 10-mm diameter bifilm, when raveled and compacted by turbulence to around 1 mm diameter, can pass through with ease. Thus, the filter is not capable of filtering out bifilms. Fortunately, however, filters are effective in resisting the passage of bubbles. This is really important during the priming of the filling system, the early seconds of filling when the 100% air in the system is required to be displaced by 100% metal. The transition is unfortunately often messy and ragged, so that priming bubbles are a major component of the early flow regime, and need to be kept out of the casting. If they succeed to enter the casting they create a long ‘bubble trail,’ a kind of lengthy bifilm and leak path from the bottom to the top of the casting. The fact that bubbles are greatly damaging to the casting has been realized only relatively recently (Ref 8).

The current paper presents the results of an approach to test the behavior of filling systems designed to fill completely (Ref 8), thereby excluding all air so far as possible, and thereby reduce or prevent the occurrence of surface turbulence and the entrainment of bubbles and bifilms. Naturally, it is necessary that the systems are practical and economic, permitting their use for medium and heavy cast steel casting manufacture in steel foundry plants.

The authors have in mind application of good systems in a local Polish foundry manufacturing heavy steel castings with a weight of up to around 30 tonnes, frequently in single units. Much of the molding process is carried out by hand, which provides an opportunity to shape the gating system closely to the theoretically ideal model. For such single heavy castings, failure is unthinkably costly, so that any additional help to ensure success is always welcome (Ref 9,10,11,12,13,14).

The casting manufacturing design concepts encompass an extensive body of knowledge enshrined in Campbell’s ‘Ten Rules’ (Ref 8). However, the two key elements applying to the filling system are (1) the critical velocity for the avoidance of entrainment defects (Ref 6), and (2) the avoidance of entrained air and oxide entering the mold cavity (Ref 15,16,17). Therefore, only these most important practical issues were included here for optimization. Other researchers are beginning to adopt these rules and are finding them useful (Ref 18,19,20,21).

The paper describes the systematic evaluation of a number of gating systems in current use including the extended runner, spin trap, vortex gate, trident gate and others, using computer simulation.

Experimental Method

Two computer packages: NovaFlow&Solid by NovaCast and Magma by Magmasoft, were used. A series of different gating systems were applied to a casting based on a test mold according to Polish Standard PN-H-04309: 1976 ‘Cast steel—testing, casting and sampling,’ the so-called clover test piece. This sample test shape is commonly used in Poland for the evaluation of the mechanical properties of cast steel (Fig. 1). The steel test piece weighs 20 kg.

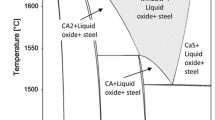

Instead of the traditional filling of the mold by top pouring, the authors evaluated a series of different bottom gated systems. Bottom gating avoids any fall of the metal inside the mold cavity. It also provides filling against the gravity, allowing the achievement of non-turbulent filling, in sharp contrast to top pouring. It is one of the aspects of filling technology strongly recommended by Campbell and others (Ref 19, 22,23,24,25). All modeling trials have been made using the steel grade GS-52 according to DIN 1681, with the pouring temperature set at 1570 °C. The nominal composition of this steel is < 0.30% C; 0.30-0.60% Si; 0.20-0.50% Mn; < 0.04% P; < 0.04% S. The minimum mechanical properties of the steel are YS = 260 MPa, UTS = 520 MPa, E = 18%, impact strength ISO-V = 22 J.

The sprue entrance is considered in every case to be completely filled by liquid metal. This is rarely met in practice unless one of only two conditions is met: (1) The entrance is filled by an offset step basin with a stopper sealing the sprue entrance. The stopper is raised, permitting the fill of the sprue only when the basin is filled up to the design fill level. (2) The sprue is filled by direct contact with the nozzle of a bottom-pour ladle; a technique known as ‘contact pouring.’ Both of these techniques are known to be essential for the production of low-defect castings (Ref 8).

It is important to bear in mind that practically all currently available computer packages are unable to model the presence of bubbles in the flow of liquids. This means that an important aspect of gating design cannot be simulated, so that all current attempts at simulation unfortunately remain limited. Nevertheless, the authors believe that the present work illustrates that much can be achieved and demonstrates important improvements which the application of recent concepts make possible.

State-of-the-Art Pouring Procedure

A conventional gating system constructed by using prefabricated 15-mm diameter refractory tubes was simulated as a base against which newer developments could be assessed. In this case, the rate of metal flow from the ladle was 5 kg/s. Figure 2 presents a distribution of metal velocity and a fill tracker that defines a distribution and life time of metal portion entering the sprue after 1, 2 and 4 s from the beginning of pouring. It can be noticed that the velocity of the metal at the entrance to the mold cavity exceeds 3 m/s, greatly exceeding the safe gate velocity 0.5 m/s, resulting in a clear jetting effect. The numerous splashes and droplets would result in a poor-quality casting with generous quantities of entrained defects. The impacts between droplets and splashes will create oxide bifilms (Ref 15) which will degrade the mechanical properties and the appearance of the casting.

Tapering of the Down-Sprue

The poor performance of the basic pipework system seen in Fig. 2 raises the question, ‘What should the perfect gating system look like?’ There are a number of options. But some clear process steps include the following factors.

First, in place of constant diameter preformed refractory tubes, the cross-sectional shape of the filling system channels requires to be tailored to the shape of the flowing liquid. Almost all bottom-pour ladles have round-shaped nozzles which need to match the shape of the entrance to the gating system. From that point onwards in the filling system, the sprue’s cross section should gradually narrow, tapering according to the natural hyperbolic curve of a falling stream. The authors in their most recent studies confirmed (Ref 26) that liquid metal flowing through runners with larger perimeter but the same cross-sectional area tend to behave differently: the slimmer the runner the more laminar the flow. A slim rectangular runner 30 × 6 mm was therefore selected. As a consequence, the sprue had the additional requirement to change gradually from a circular cross section at its entrance, to a rectangle at its exit, to match perfectly to the entrance to the runner.

The sophisticated shape of the sprue described above contrasts with a commonly used junction of a round sprue to a rectangular runner. This junction works badly, with the liquid ricocheting back and forth down the runner, never properly filling the runner, as shown schematically in Fig. 3 (Ref 8). The improved sprue design by the authors for this simulation is shown in Fig. 4.

The studies show that improper tapering and transition causes, as shown in Fig. 5, depressurization and non-filling of the sprue. The metal stream clearly free-falls down the early part of the sprue, and so does not have the advantage of some boundary friction. The higher velocity into the mold is seen to cause jetting. However, it should be realized that the real situation is more damaging still as a result of the simulation not modeling bubbles. The plunging stream conditions in the sprue will entrain copious volumes of air, probably in a mix of at least 50/50 air/metal. This massive influx of air will severely damage the casting by both bifilm and bubble entrainment (Ref 7).

Extended Runner

Another traditional filling system uses a simple extension of the runner to capture the first metal through the system because it was assumed to be relatively cold. This was true, but probably of negligible importance. Close examination of Fig. 6 shows no great benefit to metal temperature through the gate. In any case, the real problem requiring solution was not lack of temperature, but excess of defects resulting from its unavoidable mixing with air in the initially empty filling channels. In particular, its content of bubbles would add to the problems of a significant bifilm population already generated.

Figure 6 presents the distribution of velocity during the filling. It is clear that while the extension is filling, the velocity through the gate is close to a gentle and safe value in the range 0.5-1.0 m/s. However, at the instant the extension is filled, the gate is now subject to the full pressure head of the sprue, and a jet is formed; the velocity of metal entering the mold cavity has jumped to over 2 m/s. This disturbance to the rising surface of the melt is seen to continue high into the mold, leading to bifilm formation and laps on the casting surface (the lap constituting a bifilm crack defect) which may lead to macroscopic cracking of the casting.

In addition, the small volume of the extension causes a back wave (which would have been expected to be even more significant if the runner had been deeper, allowing more ‘head room’ for back-flow). Some back-flow from the extension into the casting is clearly seen in the tracking result, confirming that some of the damaged melt will find its way into the casting. The authors tried different modifications of this solution, but even increasing the extension to the top of the mold did not result in the elimination of the jetting effect.

Centrifugal Slag Trap

Various versions of a centrifugal slag traps have been described in the literature for a long time. It may be built in a number of ways, but one thing is constant—the component to be used as a spin trap is located in front of the mold cavity. The authors performed many simulations using a number of different diameter-to-height ratios, but the effect was always similar to that presented in Fig. 7. The technique initially looks promising, but the trap finally fills, which causes a sudden increase in velocity with a consequential catastrophic jetting effect. Impurities originally held in the middle of the trap are pushed inside the mold cavity. The centrifugal slag trap cannot be recommended.

The above system was not easily molded, requiring multiple vertical partings or the use of complex cores. An analogous design, a ‘barrel trap,’ was devised by authors to create a system similar to the centrifugal slag trap, but because of the horizontal axis of the ‘barrel’ it would be easier to mold. A filter placed flush with the runner was provided to divert bubbles (and other less dense components such as slag) into the barrel where they could be centrifuged into its center. However, the computer simulation revealed a similar problem to the slag trap; when the filling of the barrel was complete, the centrifugally concentrated impurities appear to flow back to the filter, either clogging the filter or reducing the casting quality. It seems the barrel trap is yet another technique which cannot be recommended.

Vortex Gate

The vortex gate (Fig. 8) enjoyed some early success for larger castings by reducing the high velocity of metal entering the mold cavity. Its huge ability to reduce velocity resulted simply from the ratio of areas of the runner and the vortex cylinder, being the ratio of the horizontal flow area to the vertical flow area. It was not difficult to reduce flow velocity by a factor of 10. At that time, such large velocity reductions were not easily achieved by any other simple technique.

The cylinder was equipped with a ‘collar’ around its base (described elsewhere as a spinner disk) to guide the initial metal around the cylinder, gaining its circular motion, and avoiding its direct impact and splashy vertical climb up the far wall of the cylinder. Another feature of the vortex gate was a ceramic foam filter placed on the top in an effort to reduce the rotational component of speed before it entered the mold.

As shown in Fig. 8, the velocity of metal entering the mold cavity in this solution is 0.78 m/s, which makes a significant improvement compared to previous systems, but the rotational flow of the first portions of metal entering the mold cavity remains too turbulent. (The limited effectiveness of the foam filter in reducing the rotational speed is confirmed by practical experience. It may have been improved by the use of straight vertical pores of a pressed or extruded filter.)

From practical trials, however, it has been found that a major fault with the vortex gate is that it centrifuges bubbles into the center of the vortex cylinder from where they are unable to escape. They build up and coalesce to a single bubble, which grows in size under the filter until it has sufficient buoyancy to force though the filter. The flow up through the casting is highly damaging to the casting; the long bubble trails generate long bifilm cracks and leak paths. (Unfortunately, the deleterious action of bubbles in the flowing metal, a major feature, cannot yet be simulated as mentioned above.)

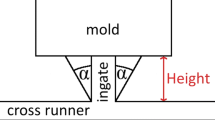

The Tangential (Flush) Filter and Terminal Spin Trap

In this filling system (Fig. 10), the vertical ingate is protected from the ingress of bubbles by a filter which acts as a bubble diverter. The filter is placed flush with the top of the runner so that, instead of the bubbles accumulating under the filter, they are encouraged to flow past and into the runner extension. The bubbles are then trapped, together with the cool and damaged priming metal, by the centrifugal action inside the spinner.

The spinner at the end of the runner has a further important role; the gradual filling of the trap causes a steady increase in back pressure in the runner. This pressure, effectively starting from zero, acts to drive the initial slow filling of the gate, ensuring that the velocity through the gate is too low to cause jetting. This is clearly achieved as shown in Fig. 9 and 10. Only when the trap is filled does the full head height of the sprue come into action, and the velocity through the gate reaches its full value of several meters per second. The volume of the trap needs to be sufficiently large to ensure that the trap only fills after the gate is filled, and sufficient depth of metal has arrived in the mold cavity to suppress jetting. The height-to-diameter ratio of a spin trap, and its optimum volume as a function of casting size and geometry, will be subject to further examination.

A further feature of this filling system should be noted. Because the sprue is nicely tapered, so as to fill completely and thereby exclude air, and because air bubbles from the priming of the system are encouraged to divert, instead of passing through the filter, the filter transmits only relatively good quality metal rather than masses of oxides. In practice, therefore, it is successful to pass large volumes of metal without any danger of blockage. This behavior contrasts with the use of filter placed after ‘drain pipe’ sprues, which generate so much oxide that the filter can pass only limited quantities of metal prior to blocking (Ref 27).

Naturally, the cross section of the ingate should be sufficiently large to reduce the speed of metal entering the mold cavity to a value in or below the range 0.5-1.0 m/s. In Fig. 11, the initial velocity of metal entering the mold cavity is 0.3 m/s.

The Tangential (Flush) Filter and Terminal Spin Trap Made from Preformed Refractory Tubes

If the filling system is constructed from prefabricated refractory tubes, for ease of assembly and molding, instead of being molded directly in sand, Fig. 12 shows the result. The initial velocity of metal in the mold cavity is around 0.6 m/s; however, jetting effect is evident. Although this filling behavior might appear marginally acceptable, the constant diameters of the preformed tubes cannot follow the necessarily changing form of the liquid stream, and do not therefore constrain the flow. As a result, air entrainment and bubble formation will occur (not easily detected in the simulations), which will further degrade flow and the quality of the casting beyond what Fig. 12 can show. The use of the preformed tubes for filling systems cannot be recommended at this time.

Trident Gate

The trident gate is the most recent development in the quest for reliable, high-quality, gravity casting techniques (Ref 27).

In common with the previous technique, it has a filter flush with the runner to avoid bubbles so far as possible, and the provision of a spin trap which not only captures bubbles and damaged metal, but raises the pressure slowly on the ingate filter to avoid jetting into the mold.

As an additional feature, it has a bubble trap and second filter placed vertically, so if any bubbles get through the first filter, the second filter would divert them upwards into the bubble trap.

The system was devised by Puhakka and Campbell in 2014 (Ref 27). The schematic diagram of a trident gate is shown in Fig. 13. Its rather complex form is not easily molded, and so is contained within a two-parted sand core, having an outward block-like shape, which is planted on the runner and molded into place in the sand mold. This solution has been used with great success with aluminum alloys (Ref 28,29,30). It appears to be capable of routinely making defect-free Al alloy castings. The technique may also be useful for ferrous alloys but has yet to be widely tested in practice.

Figure 13 presents a simulation of metal velocity. During the initial phase of mold cavity filling, the velocity is around 0.35 m/s. The analysis of fill trackers presented in Fig. 14 shows that filling is equally good as in the case of spin trap solution. Overall, in addition to the advantages of a spin trap its two-stage filtration plus integral bubble trap appears to be highly effective in keeping bubbles out of the mold cavity.

Conclusions

The paper presents a systematic comparison of a number of gating systems for steel castings, using computer simulation. They were based on the filling of a clover-like test sample and led to the following conclusions:

-

Computer modeling confirmed the effectiveness of gating systems to control the velocity and surface turbulence of the metal entering the mold cavity (but it is acknowledged that the simulations could not include the presence of air bubbles in the metal flow).

-

Filling systems molded to follow the shape of the falling stream (particularly the naturally pressured system) are successful to reduce the conditions for forming entrainment defects.

-

The filling system constructed from preformed refractory tubes performed poorly.

-

The various vortex systems were all found to perform poorly for different reasons.

-

The various systems using (1) naturally pressurized channel designs; (2) filters placed flush on runners to divert bubbles; and (3) sufficiently large spin traps on the ends of runners performed excellently. For the first time, it seems that techniques are now available for the production of defect-free castings.

References

M. Soinski, P. Kordas, and K. Skurka, Trends in the Production of Castings in the World and in Poland in the XXI, Century, Arch. Foundry Eng., 2016, 16(2), p 5–10

M. Holtzer, R. Danko, and S. Zymankowska-Kumon, The State of Art and Foresight of World’s Casting Production, Metalurgija, 2014, 53(4), p 697–700

J. Danko and M. Holtzer, The State of Art and Foresight of World’s Casting Production, Metalurgija, 2006, 45(4), p 333–340

L. Camek, P. Lichy, I. Kroupova, J. Duda, J. Beno, M. Korbas, F. Radkovsky, and S. Bliznyukov, Effect of Cast Steel Production Metallurgy on the Emergence of Casting Defects, Metalurgija, 2016, 55(4), p 701–704

E. Foglio, M. Gelfi, A. Pola, S. Goffelli, and D. Lusuardi, Fatigue Characterization and Optimization of the Production Process of Heavy Section Ductile Iron Castings, Int. J. Metalcast., 2017, 11(1), p 33–43

J. Campbell, Stop Pouring, Start Casting, Int. J. Metalcast., 2012, 6(3), p 7–18

J. Campbell, Melting, Remelting, and Casting for Clean Steel, Steel Res. Int., 2017, 88(1), p 1600093

J. Campbell, Complete Casting Handbook, 2nd ed., Butterworth-Heinemann, Oxford, 2015

S.G. Acharya, J.A. Vadher, and K.D. Kothari, Evaluation of Critical Parameters for Sand Inclusion Defect in FNB Casting, Arch. Foundry Eng., 2017, 17(1), p 5–12

S.G. Acharya, J.A. Vadher, and P.V. Kanjariya, Identification and Quantification of Gases Releasing From Furan No Bake Binder, Arch. Foundry Eng., 2016, 16(3), p 5–10

P. David, J. Massone, R. Boeri, and J. Sikora, Gating System Design to Cast Thin Wall Ductile Iron Plates, Int. J. Cast Met. Res., 2006, 19(2), p 98–109

G.L. Di Muoio and N.S. Tiedje, Achieving Control of Coating Process in your Foundry, Arch. Foundry Eng., 2015, 15(4), p 110–114

A. Modaresi, A. Safikhani, A. Noohi, N. Hamidnezhad, and S. Maki, Gating System Design and Simulation of Gray Iron Casting to Eliminate Oxide Layers Caused by Turbulence, Int. J. Metalcast., 2017, 11(2), p 328–339

Z. Ignaszak, Discussion on Usability of the Niyama Criterion for Porosity Predicting in Cast Iron Castings, Arch. Foundry Eng., 2017, 17(3), p 196–204

J. Campbell, The Consolidation of Metals: The Origin of Bifilms, J. Mater. Sci., 2016, 51(1), p 96–106

J. Campbell, Sixty Years of Casting Research, Metall. Mater. Trans. A, 2015, 46A(11), p 4848–4853

J. Campbell, Crack Populations in Metals, Aims Mater. Sci., 2016, 3(4), p 1436–1442

F. Hsu, M. Jolly, and J. Campbell, Vortex-Gate Design for Gravity Casting, Int. J. Cast Met. Res., 2006, 19(1), p 38–44

F. Hsu, M. Jolly, and J. Campbell, A Multiple-Gate Runner System for Gravity Casting, J. Mater. Process. Technol., 2009, 209(17), p 5736–5750

R. Ahmad and M. Hashim, Effect of Vortex Runner Gating System on the Mechanical Strength of al-12si Alloy Castings, Arch. Metall. Mater., 2011, 56(4), p 991–997

N. Ducic, R. Slavkovic, I. Milicevic, Z. Cojbasic, S. Manasijevic, and R. Radisa, Optimization of the Gating System for Sand Casting Using Genetic Algorithm, Int. J. Metalcast., 2017, 11(2), p 255–265

H. Zhou, L. Luo, Z. Shi, J. Dong, and W. Ma, Filling Pattern of Step Gating System in Lost Foam Casting Process and Its Application, Adv. Mater. Res.-Switz, 2013, Pts 1–3, 602-604, p 1916–1921

D. Yang, S. Li, F. He, W. Sung, J. Kao, and R. Chen, Twin Gating System Design for Typical Thin Wall Stainless Steel Castings Based on Fast Pouring Mechanism, Appl. Mech. Mater., 2014, Pts 1 and 2, 457-458, p 1657–1660

R. Ranjan, N. Kumar, R. Pandey, and M. Tiwari, Agent-Based Design Framework for Riser and Gating System Design for Sound Casting, Int. J. Prod. Res., 2004, 42(22), p 4827–4847

K. Renukananda and B. Ravi, Multi-Gate Systems in Casting Process: Comparative Study of Liquid Metal and Water Flow, Mater. Manuf. Process., 2016, 31(8), p 1091–1101

J. Jezierski, R. Dojka, K. Kubiak, W. Zurek, and T. Ltd, Experimental Approach for Optimization of Gating System in Castings, Metal 2016: 25th Anniversary International Conference on Metallurgy and Materials, 2016, p 104–109

J. Campbell, Mini Casting Handbook, Aspect Design, Malvern, 2017

M. Bruna, D. Bolibruchova, and R. Pastircak, Reoxidation Processes Prediction in Gating System by Numerical Simulation for Aluminium Alloys, Arch. Foundry Eng., 2017, 17(3), p 23–26

J. Sturm, G. Dieckhues, and S. Sikorski, Systematic Optimization of Aluminum Sand Casting Gating Systems, Trans. Am. F, 2012, 120(120), p 13–21

Y. Jiang, Y. He, Y. He, X. Qian, Y. Huang, L. Xu, W. Tian, and E. Mao, Analysis and Optimization on the Gating System of Aluminum Alloy Piston in Casting, Appl. Mech. Mater., 2011, Pts 1 and 2, 80-81, p 32–35

Author information

Authors and Affiliations

Corresponding author

Additional information

J. Campbell: Professor Emeritus.

This article is an invited submission to JMEP selected from presentations at the Symposium “Solidification, Casting, Foundry and Liquid Metal Processing,” belonging to the Topic “Joining” at the European Congress and Exhibition on Advanced Materials and Processes (EUROMAT 2017), held September 17-22, 2017, in Thessaloniki, Greece, and has been expanded from the original presentation.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Dojka, R., Jezierski, J. & Campbell, J. Optimized Gating System for Steel Castings. J. of Materi Eng and Perform 27, 5152–5163 (2018). https://doi.org/10.1007/s11665-018-3497-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3497-1