Abstract

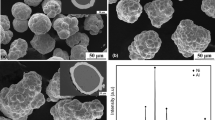

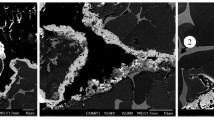

Properties of plasma-sprayed ceramic coatings can be improved significantly by reinforcing such coatings with carbon nanotube (CNT). However, it is difficult to disperse CNT in the plasma spray feedstock owing to its tendency to form agglomerate. A colloidal processing technique, namely heterocoagulation, is effective in bringing about unbundling of CNT, followed by its homogeneous dispersion in the ceramic powder. This report deals with the mixing of micro-sized crushed titania and agglomerated alumina powders with CNT using the heterocoagulation technique. Heterocoagulation of titania was attempted with both cationic and anionic surfactants, and the latter was found to be more effective. Mixing of the oxides and carbon nanotube was also accomplished in a ball mill either in a dry condition or in alcohol, and powders thus obtained were compared with the heterocoagulated powder. The heterocoagulated powder has shown a more homogeneous dispersion of CNT in the oxide. The coatings produced from the heterocoagulated powder demonstrated improvement in hardness, porosity, indentation fracture toughness and elastic modulus. This is attributed to CNT reinforcement.

Similar content being viewed by others

References

K. Sabiruddin, J. Joardar, and P. Bandyopadhyay, Analysis of Phase Transformation in Plasma Sprayed Alumina Coatings Using Rietveld Refinement, Surf. Coat. Technol., 2010, 204, p 3248–3253

V. Bolleddu, V. Racherla, and P. Bandyopadhyay, Microstructural and Tribological Characterization of Air Plasma Sprayed Nanostructured Alumina-Titania Coatings Deposited with Nitrogen and Argon as Primary Plasma Gases, Mater. Des., 2014, 59, p 252–263

G. Bolelli, K. Sabiruddin, L. Lusvarghi, E. Gualtieri, S. Valeri, and P. Bandyopadhyay, FIB Assisted Study of Plasma Sprayed Splat-Substrate Interfaces: NiAl-Stainless Steel and Alumina-NiAl Combinations, Surf. Coat. Technol., 2010, 205, p 363–371

P. Bandyopadhyay, M. Hadad, and C. Jaeggi, Microstructural, Tribological and Corrosion Aspects of Thermally Sprayed Ti-Cr-Si Coatings, Surf. Coat. Technol., 2008, 203, p 35–45

P. Bandyopadhyay and S. Siegmann, Friction and wear Behavior of Vacuum Plasma-Sprayed Ti-Zr-Ni Quasicrystal Coatings, Surf. Coat. Technol., 2005, 197, p 1–9

K. Sabiruddin, P. Bandyopadhyay, G. Bolelli, and L. Lusvarghi, Variation of Splat Shape with Processing Conditions in Plasma Sprayed Alumina Coatings, J. Mater. Process. Technol., 2011, 211, p 450–462

S. Das, T. Bandyopadhyay, S. Ghosh, A. Chattopadhyay, and P. Bandyopadhyay, Processing and Characterization of Plasma-Sprayed Ceramic Coatings on Steel Substrate: Part I. On Coating Characteristics, Metall. Mater. Trans. A, 2003, 34, p 1909–1918

S. Das, T. Bandyopadhyay, S. Ghosh, A. Chattopadhyay, and P. Bandyopadhyay, Processing and Characterization of Plasma-Sprayed Ceramic Coatings on Steel Substrate: Part II. On Coating Performance, Metall. Mater. Trans. A, 2003, 34, p 1919–1930

N. Berger-Keller, G. Bertrand, C. Filiatre, C. Meunier, and C. Coddet, Microstructure of Plasma-Sprayed Titania Coatings Deposited from Spray-Dried Powder, Surf. Coat. Technol., 2003, 168, p 281–290

P.P. Bandyopadhyay, V.K. Balla, S. Bose, and A. Bandyopadhyay, Compositionally Graded Aluminum Oxide Coatings on Stainless Steel Using Laser Processing, J. Am. Ceram. Soc., 2007, 90, p 1989–1991

P. Bandyopadhyay, D. Chicot, B. Venkateshwarlu, V. Racherla, X. Decoopman, and J. Lesage, Mechanical Properties of Conventional and Nanostructured Plasma Sprayed Alumina Coatings, Mech. Mater., 2012, 53, p 61–71

S.R. Bakshi, V. Singh, S. Seal, and A. Agarwal, Aluminum Composite Reinforced with Multiwalled Carbon Nanotubes from Plasma Spraying of Spray Dried Powders, Surf. Coat. Technol., 2009, 203, p 1544–1554

E. Zapata-Solvas, D. Gómez-García, and A. Dominguez-Rodriguez, Towards Physical Properties Tailoring of Carbon Nanotubes-Reinforced Ceramic Matrix Composites, J. Eur. Ceram. Soc., 2012, 32, p 3001–3020

A. Morales-Rodríguez, A. Gallardo-López, A. Fernández-Serrano, R. Poyato, A. Muñoz, and A. Domínguez-Rodríguez, Improvement of Vickers Hardness Measurement on SWNT/Al2 O3 Composites Consolidated by Spark Plasma Sintering, J. Eur. Ceram. Soc., 2014, 34, p 3801–3809

K. Balani and A. Agarwal, Process Map for Plasma Sprayed Aluminum Oxide-Carbon Nanotube Nanocomposite Coatings, Surf. Coat. Technol., 2008, 202, p 4270–4277

K. Balani, S.R. Bakshi, Y. Chen, T. Laha, and A. Agarwal, Role of Powder Treatment and Carbon Nanotube Dispersion in the Fracture Toughening of Plasma-Sprayed Aluminum Oxide—Carbon Nanotube Nanocomposite, J. Nanosci. Nanotechnol., 2007, 7, p 3553–3562

J. Sun and L. Gao, Development of a Dispersion Process for Carbon Nanotubes in Ceramic Matrix by Heterocoagulation, Carbon, 2003, 41, p 1063–1068

J. Sun, L. Gao, and W. Li, Colloidal Processing of Carbon Nanotube/Alumina Composites, Chem. Mater., 2002, 14, p 5169–5172

S.C. Jambagi, N. Sarkar, and P. Bandyopadhyay, Preparation of Carbon Nanotube Doped Ceramic Powders for Plasma Spraying Using Heterocoagulation Method, J. Eur. Ceram. Soc., 2015, 35, p 989–1000

K. Esumi and M. Ueno, Structure-Performance Relationships in Surfactants, 2nd ed., CRC Press, Florida, 2003

L.-Y. Chai, Y.-F. Yu, G. Zhang, P. Bing, and S-w Wei, Effect of Surfactants on Preparation of Nanometer TiO2 by Pyrohydrolysis, Trans. Nonferrous Met. Soc. China, 2007, 17, p 176–180

K. Esumi, S. Uda, M. Goino, K. Ishiduki, T. Suhara, H. Fukui, and Y. Koide, Adsorption of Cationic Surfactants on Titanium Dioxide with a Hydrophobic Group Anchor and Their Adsolubilization Behaviors, Langmuir, 1997, 13, p 2803–2807

N.B. Saleh, L.D. Pfefferle, and M. Elimelech, Aggregation Kinetics of Multiwalled Carbon Nanotubes in Aquatic Systems: Measurements and Environmental Implications, Environ. Sci. Technol., 2008, 42, p 7963–7969

F. Inam, H. Yan, M.J. Reece, and T. Peijs, Dimethylformamide: An Effective Dispersant for Making Ceramic-Carbon Nanotube Composites, Nanotechnology, 2008, 19, p 195710

A.K. Keshri, J. Huang, V. Singh, W. Choi, S. Seal, and A. Agarwal, Synthesis of Aluminum Oxide Coating with Carbon Nanotube Reinforcement Produced by Chemical Vapor Deposition for Improved Fracture and wear Resistance, Carbon, 2010, 48, p 431–442

P. He, G. Ma, H. Wang, Q. Yong, and S. Chen, Microstructure and Mechanical Properties of a Novel Plasma-Spray TiO2 Coating Reinforced by CNTs, Ceram. Int., 2016, 42, p 13319–13325

E. Rocha-Rangel, Fracture Toughness Determinations by Means of Indentation Fracture, Nanocomposites with Unique Properties and Applications in Medicine and Industry, Dr. John Cuppoletti, Ed., InTech, 2011, p 21–38

S.C. Jambagi, S. Kar, P. Brodard, and P. Bandyopadhyay, Characteristics of Plasma Sprayed Coatings Produced from Carbon Nanotube Doped Ceramic Powder Feedstock, Mater. Des., 2016, 112, p 392–401

D.A. Hanaor and S.C. Sorrell, Review of the Anatase to Rutile Phase Transformation, J. Mater scie, 2011, 46, p 855–874

J. Kim and S. Kang, Stable Phase Domains of the TiO2-Ti3O5-Ti2O3-TiO-Ti(CxOy)-TiC System Examined Experimentally and Via First Principles Calculations, J Mater. Chem. A, 2014, 2, p 2641–2647

Acknowledgments

The Malvern DLS instrument used for the measurement of zeta potential has been procured under a project sponsored by the Department of Science and Technology (DST), Government of India.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jambagi, S.C., Agarwal, A., Sarkar, N. et al. Plasma-Sprayed Titania and Alumina Coatings Obtained from Feedstocks Prepared by Heterocoagulation with 1 wt.% Carbon Nanotube. J. of Materi Eng and Perform 27, 2364–2372 (2018). https://doi.org/10.1007/s11665-018-3319-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3319-5