Abstract

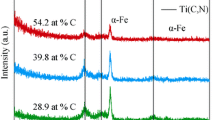

To improve the practical property of (Ti,Al)N coating on a high-speed steel (HSS) substrate, a series of sputtering currents were used to obtain several (Ti,Al)N coatings using a magnetron sputtering equipment. The phase structure, morphology, and components of (Ti,Al)N coatings were characterized by x-ray diffraction, scanning electron microscopy, energy-dispersive x-ray spectroscopy, and x-ray photoelectron spectroscopy, respectively. The performance of (Ti,Al)N coatings, adhesion, hardness, and wear resistance was tested using a scratch tester, micro/nanohardness tester, and tribometer, respectively. Based on the structure–property relationships of (Ti,Al)N coatings, the results show that both the Al content and deposition temperature of (Ti,Al)N coatings increased with sputtering current. A high Al content helped to improve the performance of (Ti,Al)N coatings. However, the HSS substrate was softened during the high sputtering current treatment. Therefore, the optimum sputtering current was determined as 2.5 A that effectively increased the hardness and wear resistance of (Ti,Al)N coating.

Similar content being viewed by others

References

J. Wang, Y.B. Liu, J. An, and L.M. Wang, Wear Mechanism Map of Uncoated HSS Tools During Drilling Die-Cast Magnesium Alloy, Wear, 2008, 265, p 685–691

V. Braic, C.N. Zoita, M. Balaceanu, A. Kiss, A. Vladescu, A. Popescu, and M. Braic, TiAlN/TiAlZrN Multilayered Hard Coatings for Enhanced Performance of HSS Drilling Tools, Surf. Coat. Technol., 2010, 204, p 1925–19288

R. Venkatesh, V.S. Rao, N. Arunkumar, S. Biswas, and R.S. Kumar, Wear Analysis on Silicon Carbide Coated HSS Pin on SS Disc Substrate, Proc. Mater. Sci., 2015, 10, p 644–650

W.W. Wu, W.L. Chen, S.B. Yang, Y. Lin, S.H. Zhang, and T.Y. Cho, Design of AlCrSiN Multilayers and Nanocomposite Coating for HSS Cutting Tools, Appl. Surf. Sci., 2015, 351, p 803–810

Z. Zheng and Z. Yu, Characteristics and Machining Applications of Ti(Y)N Coatings, Surf. Coat. Technol., 2010, 204, p 4107–4113

L. Chen, M. Moser, Y. Du, and P.H. Mayrhofer, Compositional and Structural Evolution of Sputtered Ti-Al-N, Thin Solid Films, 2009, 517, p 6635–6641

A. Rizzo, L. Mirenghi, M. Massaro, U. Galietti, L. Capodieci, R. Terzi, L. Tapfer, and D. Valerini, Improved Properties of TiAlN Coatings Through the Multilayer Structure, Surf. Coat. Technol., 2013, 235, p 475–483

L. Chen, K.K. Chang, Y. Du, J.R. Li, and M.J. Wu, A Comparative Research on Magnetron Sputtering and Arc Evaporation Deposition of Ti-Al-N Coatings, Thin Solid Films, 2011, 519, p 3762–3767

J.Y. Yan, D.J. Li, L. Dong, C.K. Gao, N. Wang, X.Y. Deng, H.Q. Gu, R.X. Wan, and X. Sun, The Modulation Structure Induced Changes in Mechanical Properties of TiAlN/Al2O3 Multilayers, Nucl. Instrum. Methods Phys. Res. Sect. B, 2013, 307, p 123–126

H. Du, H. Zhao, and J.G. Xian, Effect of Interlayers on the Structure and Properties of TiAlN Based Coatings on WC-Co Cemented Carbide Substrate, Int. J. Refract. Metals Hard Mater., 2013, 37, p 60–66

L. Tomaszewski, W. Gulbinski, A. Urbanowicz, T. Suszko, A. Lewandowski, and W. Gulbinski, TiAlN Based Wear Resistant Coatings Modified by Molybdenum Addition, Vacuum, 2015, 121, p 223–229

L.H. Zhu, M.M. Hu, W.Y. Ni, and Y.X. Liu, Effect of Al Content on Adhesion Strength of TiAlN Coatings, Vacuum, 2012, 12, p 1795–1799

M.A. Al-Bukhaiti, K.A. Al-hatab, W. Tillmann, F. Hoffmann, and T. Sprute, Tribological and Mechanical Properties of Ti/TiAlN/TiAlCN Nanoscale Multilayer PVD Coatings Deposited on AISI, H11 Hot Work Tool Steel, Appl. Surf. Sci., 2014, 318, p 180–190

T. Mori, M. Noborisaka, T. Watanabe, and T. Suzuki, Oxidation Resistance and Hardness of TiAlSiN/CrAlYN Multilayer Films Deposited by the Arc Ion Plating Method, Surf. Coat. Technol., 2012, 213, p 216–220

A. Inspektor and P.A. Salvador, Architecture of PVD Coatings for Metalcutting Applications: A Review, Surf. Coat. Technol., 2014, 257, p 138–153

G.S. Fox-Rabinovich, B.D. Beake, J.L. Endrino, S.C. Veldhuis, R. Parkinson, L.S. Shuster, and M.S. Migranov, Effect of Mechanical Properties Measured at Room and Elevated Temperatures on the Wear Resistance of Cutting Tools with TiAlN and AlCrN Coatings, Surf. Coat. Technol., 2006, 200, p 5738–5742

P. Panjan, B. NavinŠek, M. Čekada, and A. Zalarb, Oxidation Behaviour of TiAlN Coatings Sputtered at Low Temperature, Vacuum, 1999, 53, p 127–131

A. Obrosov, R. Gulyaev, M. Ratzke, A.A. Volinsky, S. Bolz, M. Naveed, and S. Wei, XPS and AFM Investigations of Ti-Al-N Coatings Fabricated Using DC Magnetron Sputtering at Various Nitrogen Flow Rates and Deposition Temperatures, Metals, 2017, 7, p 1–10

S. Sveen, J.M. Andersson, R.M. Saoubi, and M. Olsson, Scratch Adhesion Characteristics of PVD TiAlN Deposited on High speed Steel, Cemented Carbide and PCBN Substrates, Wear, 2013, 308, p 133–141

Y.Y. Su, J.B. Wang, L.L. Tian, H.B. Zhao, M.J. Tu, and L.J. Zhao, Effect of Al Doped on Microstructure and Properties of TiN Coating, Funct. Mater., 2013, 44, p 2668–2671

K. Kutschej, P.H. Mayrhofer, M. Kathrein, P. Polcik, R. Tessadri, and C. Mitterer, Structure, Mechanical and Tribological Properties of Sputtered Ti1−xAlxN Coatings with 0.5 V ≤ x ≤ 0.75V, Surf. Coat. Technol., 2005, 200, p 2358–2365

J.C. Oliveira, A. Manaia, and A. Cavaleiro, Hard Amorphous Ti-Al-N Coatings Deposited by Sputtering, Thin Solid Films, 2008, 516, p 5032–5038

D.H. Jung, K. Moon, S.Y. Shin, and C.S. Lee, Influence of Ternary Elements (X = Si, B, Cr) on TiAlN Coating Deposited by Magnetron Sputtering Process with Single Alloying Targets, Thin Solid Films, 2013, 546, p 242–245

N. Jiang, Y.G. Shen, H.J. Zhang, S.N. Bao, and X.Y. Hou, Superhard Nanocomposite Ti-Al-Si-N Films Deposited by Reactive Unbalanced Magnetron Sputtering, Mater. Sci. Eng. B, 2006, 135, p 1–9

V. Uvarov and I. Popov, Metrological Characterization of X-ray Diffraction Methods for Determination of Crystallite Size in Nano-scale Materials, Mater. Charact., 2007, 58, p 883–891

S.P. Pemmasani, K. Valleti, and C. Gundakaram, Effect of Microstructure and Phase Constitution on Mechanical Properties of Ti1−xAl x N Coatings, Appl. Surf. Sci., 2014, 313, p 936–946

C. Wang, S. Ou, and S.Y. Chiou, Microstructures of TiN, TiAlN and TiAlVN Coatings on AISI, M2 Steel Deposited by Magnetron Reactive Sputtering, Trans. Nonferrous Metals Soc. China, 2014, 24, p 2559–2565

J.Y. Yan, Y.D. Sun, D.J. Li, M.Y. Liu, L. Dong, M. Cao, and C.K. Gao, High-Temperature Stability of TiAlN/TiB2 Multilayers Grown on Al2O3 Substrates Using IBAD, Surf. Coat. Technol., 2013, 229, p 105–108

W.Z. Li, H.W. Liu, M. Evaristo, T. Polcar, and A. Cavaleiro, Influence of Al Content on the Mechanical Properties and Thermal Stability in Protective and Oxidation Atmospheres of Zr-Cr-Al-N Coatings, Surf. Coat. Technol., 2013, 236, p 239–245

Y.Y. Su, X. Gui, D. Xie, and S.Y. Li, The Effect of a TiN Interlayer on the Tribological Properties of Diamond-Like Carbon Films Deposited on 7A04 Aluminum Alloy, IEEE Trans. Plamsa Sci., 2011, 39, p 3144–3148

P. Li, L. Chen, S.Q. Wang, B. Yang, Y. Du, J. Li, and M.J. Wu, Microstructure, Mechanical and Thermal Properties of TiAlN/CrAlN Multilayer Coatings, Int. J. Refract. Metals Hard Mater., 2013, 40, p 51–57

B. Grossmann, N. Schalk, C. Czettl, M. Pohler, and C. Mitterer, Phase Composition and Thermal Stability of Arc Evaporated Ti1–xAlxN Hard Coatings with 0.4 ≤ x ≤ 0.67, Surf. Coat. Technol., 2017, 309, p 687–693

C.L. Liang, G.A. Cheng, R.T. Zheng, and H.P. Liu, Fabrication and Performance of TiN/TiAlN Nanometer Modulated Coatings, Thin Solid Films, 2011, 520, p 813–817

Acknowledgments

This work was financially supported by the Basic and Frontier Research Program of Chongqing Municipality (cstc2016jcyjA0451), Scientific and Technological Research Program of Chongqing Municipal Education Commission (KJ1601104), The Foundation of Chongqing University of Art and Sciences (Y2015XC24, 2017RXC25), Natural Science Foundation of China (21603020), and NSAF (51275323).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Su, Y., Tian, L., Hu, R. et al. Effect of Sputtering Current on the Comprehensive Properties of (Ti,Al)N Coating and High-Speed Steel Substrate. J. of Materi Eng and Perform 27, 2381–2387 (2018). https://doi.org/10.1007/s11665-018-3314-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3314-x