Abstract

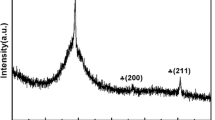

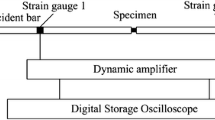

Experiments were conducted to prepare a borosilicate glass matrix composite containing 50 vol.% tungsten and examine its dynamic compressive behavior at elevated temperatures in the range of 450-775 °C. The results show that the homogenous microstructure of the tungsten/glass composite with relative density of ~ 97% can be obtained by hot-pressing sintering at 800 °C for 1 h under pressure of 30 MPa. Dynamic compressive testing was carried out by a separate Hopkinson pressure bar system with a synchronous device. The results show that the peak stress decreases and the composite transforms from brittle to ductile in nature with testing temperature increasing from 450 to 750 °C. The brittle–ductile transition temperature is about 500 °C. Over 775 °C, the composite loses load-bearing capacity totally because of the excessive softening of the glass phase. In addition, the deformation and failure mechanism were analyzed.

Similar content being viewed by others

References

S. Sakka and J.D. Mackenzie, Relation Between Apparent Glass Transition Temperature and Liquids Temperature for Inorganic Glasses, J. Non-Cryst. Solids, 1971, 6(2), p 145–162

E.L. Baker, S. DeFisher, A. Daniels, T. Vuong, J. Pham, Glass as a Shaped Charge Liner Material, in Proceedings of the 26th International Symposium on Ballistics, ed. by E. Baker, D. Templeton (Destech Publications, Lancaster, 2011), pp. 340–347

E. Hirsch, Internal Shearing During Shaped Charge Jet Formation and Break-Up, Propellants Explos. Pyrotech., 1992, 17(1), p 27–33

W. Guo, S.K. Li, F.C. Wang, and M. Wang, Dynamic Recrystallization of Tungsten in a Shaped Charge Liner, Scr. Mater., 2009, 60(5), p 329–332

A.C. Gurevitch, L.E. Murr, H.K. Shih, C.-S. Niou, A.H. Advani, D. Manuel, and L. Zernow, Characterization and Comparison of Microstructures in the Shaped-Charge Regime: Copper and Tantalum, Mater. Charact., 1993, 30(3), p 201–216

V. Cannillo, C. Leonelli, T. Manfredini, M. Montorsi, P. Veronesi, E.J. Minay, and A.R. Boccaccini, Mechanical Performance and Fracture Behaviour of Glass–Matrix Composites Reinforced with Molybdenum Particles, Compos. Sci. Technol., 2005, 65(7), p 1276–1283

E. Bernardo, G. Scarinci, and S. Hreglich, Mechanical Properties of Metal-Particulate Lead-Silicate Glass Matrix Composites Obtained by Means of Powder Technology, J. Eur. Ceram. Soc., 2003, 23(11), p 1819–1827

A.R. Boccaccini, D. Acevedo, A.F. Dericioglu, and C. Jana, Processing and Characterisation of Model Optomechanical Composites in the System Sapphire Fibre/Borosilicate Glass Matrix, J. Mater. Process. Technol., 2005, 169(2), p 270–280

I. Dlouhy and A.R. Boccaccini, Preparation, Microstructure and Mechanical Properties of Metal-Particulate/Glass-Matrix Composites, Compos. Sci. Technol., 1996, 56(12), p 1415–1424

A.A. Rubinstein and P. Wang, The Fracture Toughness of a Particulate-Reinforced Brittle Matrix, J. Mech. Phys. Solids, 1998, 46(7), p 1139–1154

A.R. Boccaccini, G. West, J. Janczak, M.H. Lewis, and H. Kern, Tensile Behavior and Cyclic Creep of Continuous Fiber-Reinforced Glass Matrix Composites at Room and Elevated Temperatures, J. Mater. Eng. Perform., 1997, 6(3), p 344–348

Y. Waku, M. Suzuki, Y. Oda, and Y. Kohtoku, Improving the Fracture Toughness of MgO–Al2O3–SiO2 Glass/Molybdenum Composites by the Microdispersion of Flaky Molybdenum Particles, J. Mater. Sci., 1997, 32(17), p 4549–4557

I. Dlouhy, M. Reinisch, A.R. Boccaccini, and J.F. Knott, Fracture Characteristics of Borosilicate Glasses Reinforced by Metallic Particles, Fatigue Fract. Eng. Mater. Struct., 1997, 20(9), p 1235–1253

M. Ferraris and E. Verne, Viscous Phase Sintering of Particle-Reinforced Glass Matrix Composites, J. Eur. Ceram. Soc., 1996, 16(4), p 421–427

M. Chen, S. Zhu, M. Shen, F. Wang, and Y. Niu, Thermophysical Properties of Alumina Particle Reinforced Glass Matrix Composites, Int. J. Appl. Ceram. Technol., 2013, 10(2), p 224–233

M. Kotoul and I. Dlouhy, Metal Particles Constraint in Glass Matrix Composites and Its Impact on Fracture Toughness Enhancement, Mater. Sci. Eng. A, 2004, 387, p 404–408

G. Banuprakash, V. Katyal, V.S.R. Murthy, and G.S. Murty, Mechanical Behaviour of Borosilicate Glass-Copper Composites, Compos. Part Appl. Sci. Manuf., 1997, 28(9–10), p 861–867

G. Otieno, A. Koos, F. Dillon, N.A. Yahya, C.E. Dancer, G.M. Hughes, N. Grobert, and R.I. Todd, Stiffness, Strength and Interwall Sliding in Aligned and Continuous Multi-walled Carbon Nanotube/Glass Composite Microcantilevers, Acta Mater., 2015, 100, p 118–125

J.E. Field, S.M. Walley, W.G. Proud, H.T. Goldrein, and C.R. Siviour, Review of Experimental Techniques for High Rate Deformation and Shock Studies, Int. J. Impact Eng., 2004, 30(7), p 725–775

J. Harding and L.M. Welsh, A Tensile Testing Technique for Fibre-Reinforced Composites at Impact Rates of Strain, J. Mater. Sci., 1983, 18(6), p 1810–1826

M. Rieth and A. Hoffmann, Influence of Microstructure and Notch Fabrication on Impact Bending Properties of Tungsten Materials, Int. J. Refract. Met. Hard Mater., 2010, 28(6), p 679–686

L. Wang, Y. Wang, A.P. Zhilyaev, A.V. Korznikov, S. Li, E. Korznikova, and T.G. Langdon, Dynamic Compressive Behavior of Ultrafine-Grained Pure Ti at Elevated Temperatures after Processing by ECAP, J. Mater. Sci., 2014, 49(19), p 6640–6647

W.S. Lee, G.L. Xiea, and C.F. Lin, The Strain Rate and Temperature Dependence of the Dynamic Impact Response of Tungsten Composite, Mater. Sci. Eng. A, 1998, 257(2), p 256–267

Acknowledgments

This work was supported by the funding of National Key Laboratory of Science and Technology on Materials under Shock and Impact under Grant No. 9140C320102150C32001 and the National Natural Science Foundation of China under Grant No. 51671030.

Conflict of Interest

None.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, C., Wang, Y., Ma, X. et al. Preparation and Dynamic Mechanical Properties at Elevated Temperatures of a Tungsten/Glass Composite. J. of Materi Eng and Perform 27, 1040–1046 (2018). https://doi.org/10.1007/s11665-018-3230-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3230-0