Abstract

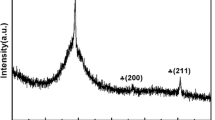

Ex situ Cu54Zr22Ti18Ni6 matrix bulk metallic glass composites (BMGCs) reinforced with Ta particles (10–30 vol.%) were fabricated by high-pressure torsion (HPT) under applied pressure of 6 GPa for 1–3 turns at temperatures of 25 or 200 °C. The densification, structure, thermal, and mechanical properties of BMGC samples were investigated by Archimedes densitometry, optical microscopy, x-ray diffraction, differential scanning calorimetry, small punch test, and microhardness measurements. Near full-density BMGC disks (relative densities higher than 0.97) are fabricated using HPT, irrespective of the processing strain and temperature. The microhardness of BMGCs is improved by increasing the number of turns, or the processing temperature due to the improvement in the deformation degree of both the amorphous and Ta particles as well as the reduction in the interlayer spacing of Ta particles. Nevertheless, there is an optimal amount of Ta which gives rise to the peak hardness in the BMGC samples, depending on the amount of imposed strain during HPT. The results of small punch test indicate that the addition of Ta to the monolithic BMG and increasing the HPT temperature significantly enhance the fracture load and deflection.

Similar content being viewed by others

References

A. Inoue, Stabilization of Metallic Supercooled Liquid and Bulk Amorphous Alloys, Acta Mater., 2000, 48, p 279–306

A.L. Greer, Metallic Glasses, Science, 1995, 267, p 1947–1953

J. Cui, J.S. Li, J. Wang, and H.C. Kou, Microstructure Evolution and Mechanical Properties of a Ti-Based Bulk Metallic Glass Composite, J. Mater. Eng. Perform., 2015, 24, p 2354–2358

M.H. Lee, J.Y. Lee, D.H. Bae, W.T. Kim, D.J. Sordelet, and D.H. Kim, A Development of Ni-Based Alloys with Enhanced Plasticity, Intermetallics, 2004, 12, p 1133–1137

H.S. Kim, P.J. Warren, B. Cantor, and H.R. Lee, Mechanical Properties of Partially Crystallized Aluminum Based Amorphous Alloys, Nanostruct. Mater., 1999, 11, p 241–247

H. Kato, K. Yubuta, D.V. Louzguine, A. Inoue, and H.S. Kim, Influence of Nanoprecipitation on Strength of Cu60Zr30Ti10 Glass Containing µm-ZrC Particle Reinforcements, Scripta Mater., 2004, 51, p 577–581

L. Liu, K.C. Chan, M. Sun, and Q. Chen, The Effect of the Addition of Ta on the Structure, Crystallization and Mechanical Properties of Zr–Cu–Ni–Al–Ta Bulk Metallic Glasses, Mater. Sci. Eng., A, 2007, 445–446, p 697–706

K. Edalati and Z. Horita, A Review on High-Pressure Torsion (HPT) from 1935 to 1988, Mater. Sci. Eng. A, 2016, 652, p 325–352

Z.M. Jiao, Z.H. Wang, R.F. Wu, T.W. Zhang, H.J. Yang, and J.W. Qiao, Dynamic Deformation Behaviors of an In Situ Ti-Based Metallic Glass Matrix Composite, J. Mater. Eng. Perform., 2016, 25, p 4729–4734

J. Das, M.B. Tang, K.B. Kim, R. Theissmann, F. Baier, W.H. Wang, and J. Eckert, “Work-Hardenable” Ductile Bulk Metallic Glass, Phys. Rev. Lett., 2005, 94, p 205501

C.C. Hays, C.P. Kim, and W.L. Johnson, Microstructure Controlled Shear Band Pattern Formation and Enhanced Plasticity of Bulk Metallic Glasses Containing In Situ Formed Ductile Phase Dendrite Dispersions, Phys. Rev. Lett., 2000, 84, p 2901–2904

P. Denisa, C.M. Meylan, C. Ebner, A.L. Greer, M. Zehetbauer, and H.-J. Fecht, Rejuvenation Decreases Shear Band Sliding Velocity in Pt-Based Metallic Glasses, Mater. Sci. Eng. A, 2017, 684, p 517–523

P. Henits, A. Revesz, and Z. Kovacs, Free Volume Simulation for Severe Plastic Deformation of Metallic Glasses, Mech. Mater., 2012, 50, p 81–87

S.-H. Joo, D.H. Phee, A.D. Setyawan, H. Kato, M. Janecek, Y.C. Kim, S. Lee, and H.S. Kim, Work-Hardening Induced Tensile Ductility of Bulk Metallic Glasses via High-Pressure Torsion, Sci. Rep., 2015, 5, p 9660

H.S. Kim, S.I. Hong, Y.S. Lee, A.A. Dubravina, and I.V. Alexandrov, Deformation Behavior of Copper During a High Pressure Torsion Process, J. Mater. Process. Technol., 2003, 142, p 334–337

X. Yang, J. Yi, S. Ni, Y. Du, and M. Song, Microstructural Evolution and Structure-Hardness Relationship in an Al-4 wt.% Mg Alloy Processed by High-Pressure Torsion, J. Mater. Eng. Perform., 2016, 25, p 1909–1915

H. Asgharzadeh, S.H. Joo, and H.S. Kim, Consolidation of Carbon Nanotube Reinforced Aluminum Matrix Composites by High-Pressure Torsion, Metall. Mater. Trans. A, 2014, 45, p 4129–4137

H. Asgharzadeh, S.H. Joo, and H.S. Kim, Al/C60 Nanocomposites Fabricated by High-Pressure Torsion, Metall. Mater. Trans. A, 2015, 46, p 1838–1842

J.Y. Kang, J.G. Kim, H.W. Park, and H.S. Kim, Multiscale Architectured Materials with Composition and Grain Size Gradients Manufactured Using High Pressure Torsion, Sci. Rep., 2016, 6, p 26590

A.P. Zhilyaev and T.G. Langdon, Using High-Pressure Torsion for Metal Processing: Fundamentals And Applications, Prog. Mater Sci., 2008, 53, p 893–979

S.-H. Joo, D.-H. Pi, J. Guo, H. Kato, S. Lee, and H.S. Kim, Enhanced Wear Resistivity of a Zr-Based Bulk Metallic Glass Processed by High-Pressure Torsion Under Reciprocating Dry Conditions, Metal Mater. Int., 2016, 22, p 383–390

J. Vierke, G. Schumacher, V.P. Pilyugin, I.A. Denks, I. Zizak, C. Wolf, N. Wanderka, M. Wollgarten, and J. Banhart, Deformation Induced Crystallization in Amorphous Al85Ni10La5 alloy, J. Alloy. Compd., 2010, 493, p 683–691

Z. Kovacs, P. Henits, A.P. Zhilyaev, and A. Revesz, Deformation Induced Primary Crystallization in a Thermally Non-Primary Crystallizing Amorphous Al85Ce8Ni5Co2 Alloy, Scripta Mater., 2006, 54, p 1733–1737

S. Hobor, Z. Kovacs, and A. Revesz, Effect of Accumulated Shear on the Microstructure and Morphology of Severely Deformed Cu60Zr30Ti10 Metallic Glass, J. Alloy. Compd., 2011, 509, p 8641–8648

J. Sort, D.C. Ile, A.P. Zhilyaev, A. Concustell, T. Czeppe, M. Stoica, S. Surinach, J. Eckert, and M.D. Baro, Cold-Consolidation of Ball Milled Fe-Based Amorphous Ribbons by High Pressure Torsion, Scripta Mater., 2004, 50, p 1221–1225

G. Abrosimova, A. Aronin, D. Matveev, and E. Pershina, Nanocrystal Formation, Structure And Magnetic Properties of Fe–Si–B Amorphous Alloy After Deformation, Mater. Lett., 2013, 97, p 15–17

T. Czeppe, G. Korznikova, J. Morgiel, A. Korznikov, N.Q. Chinh, P. Ochin, and A. Sypien, Microstructure and Properties of Cold Consolidated Amorphous Ribbons from (NiCu)ZrTiAlSi alloys, J. Alloy. Compd., 2009, 483, p 74–77

N. Van Steenberge, S. Hobor, S. Suri˜nach, A. Zhilyaev, F. Houdellier, F. Mompiou, M.D. Baro, A. Revesz, and J. Sort, Sort, Effects of Severe Plastic Deformation on the Structure And Thermo-Mechanical Properties of Zr55Cu30Al10Ni5 Bulk Metallic Glass, J. Alloy. Compd., 2010, 500, p 61–67

Y.F. Sun, H. Fujii, N. Tsuji, Y. Todaka, and M. Umemoto, Fabrication of ZrAlNiCu Bulk Metallic Glass Composites Containing Pure Copper Particles by High-Pressure Torsion, J. Alloy. Compd., 2010, 492, p 149–152

X. Sauvage, Y. Champion, R. Pippan, F. Cuvilly, L. Perrie`re, A. Akhatova, and O. Renk, Structure and Properties of a Nanoscaled Composition Modulated Metallic Glass, J. Mater. Sci., 2014, 49, p 5640–5645

H. Asgharzadeh, S.-H. Joo, J.-K. Lee, and H.S. Kim, Consolidation of Cu-based amorphous alloy powders by high-pressure torsion, J. Mater. Sci., 2015, 50, p 3164–3174

D. Meng, J. Yi, D.Q. Zhao, D.W. Ding, H.Y. Bai, M.X. Pan, and W.H. Wang, Tantalum based bulk metallic glasses, J. Non-Cryst. Solid., 2011, 357, p 1787–1790

A. Slipenyuk and J. Eckert, Correlation between enthalpy change and free volume reduction during structural relaxation of Zr55Cu30Al10Ni5 metallic glass, Scripta Mater., 2004, 50, p 39–44

A. Concustell, F.O. Mear, S. Surinach, M.D. Baro, and A.L. Greer, Structural Relaxation and Rejuvenation in a Metallic Glass Induced by Shot-Peening, Philos. Mag. Lett., 2009, 89, p 831–840

L. Krämer, K.S. Kormout, D. Setman, Y. Champion, and R. Pippan, Production of Bulk Metallic Glasses by Severe Plastic Deformation, Metals, 2015, 2, p 720–729

K.B. Kim, P.J. Warren, and B. Cantor, Structural Relaxation and Glass Transition Behavior of Novel (Ti33Zr33Hf33)50(Ni50Cu50)40Al10 Alloy Developed by Equiatomic Substitution, J. Non-Cryst. Solid., 2007, 353, p 3338–3341

Y.-K. Xu, H. Ma, J. Xu, and E. Ma, Mg-Based Bulk Metallic Glass Composites with Plasticity and Gigapascal Strength, Acta Mater., 2005, 53, p 1857–1866

B.A. Sun and W.H. Wang, The Fracture of Bulk Metallic Glasses, Prog. Mater Sci., 2015, 74, p 211–307

K.M. Flores and R.H. Dauskardt, Local Heating Associated with Crack Tip Plasticity in Zr–Ti–Ni–Cu–Be Bulk Amorphous Metals, J. Mater. Res., 1999, 14, p 638–643

Y.K. Xu and J. Xu, Ceramics Particulate Reinforced Mg65Cu20Zn5Y10 Bulk Metallic Glass Composites, Scripta Mater., 2003, 49, p 843–848

G. Chen, J.L. Cheng, and C.T. Liu, Large-sized Zr-Based Bulk-Metallic-Glass Composite with Enhanced Tensile Properties, Intermetallics, 2012, 28, p 25–33

R.T. Ott, F. Sansoz, J.F. Molinari, J. Almer, K.T. Ramesh, and T.C. Hufnagel, Micromechanics of Deformation of Metallic-Glass–Matrix Composites from In Situ Synchrotron Strain Measurements and Finite Element Modeling, Acta Mater., 2005, 153, p 883–1893

Z. Zhu, H. Zhang, Z. Hu, W. Zhang, and A. Inoue, Ta-Particulate Reinforced Zr-Based Bulk Metallic Glass Matrix Composite with Tensile Plasticity, Scripta Mater., 2010, 62, p 278–281

D.H. Bae, M.H. Lee, D.H. Kim, and D.J. Sordelet, Plasticity in Ni59Zr20Ti16Si2Sn3Ni59Zr20Ti16Si2Sn3 Metallic Glass Matrix Composites Containing Brass Fibers Synthesized by Warm Extrusion of Powders, App. Phys. Lett., 2003, 83, p 2312

D.G. Pan, H.F. Zhang, A.M. Wang, and Z.Q. Hu, Enhanced Plasticity in Mg-Based Bulk Metallic Glass Composite Reinforced with Ductile Nb Particles, App. Phys. Lett., 2006, 89, p 261904

J.B. Li, J.S.C. Jang, C. Li, S.R. Jian, P.H. Tsai, J.D. Hwang, J.C. Huang, and T.G. Nieh, Significant Plasticity Enhancement of ZrCu-Based Bulk Metallic Glass Composite Dispersed by In Situ and Ex Situ Ta Particles, Mater. Sci. Eng. A, 2012, 551, p 249–254

H. Ma, J. Xu, and E. Ma, Mg-Based Bulk Metallic Glass Composites with Plasticity and High Strength, App. Phys. Lett., 2003, 83, p 2793

Acknowledgments

The author would like to acknowledge Prof. H.S. Kim (Director of SNMPL laboratory at Pohang University of Science and Technology, POSTECH) for all of the provided support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Asgharzadeh, H. Fabrication of Ta-Reinforced Cu-Based Bulk Metallic Glass Composites by High-Pressure Torsion. J. of Materi Eng and Perform 27, 4090–4099 (2018). https://doi.org/10.1007/s11665-018-3473-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3473-9