Abstract

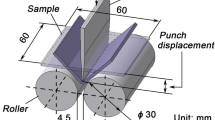

The use of warm forming for AA6xxx-T6 sheet is of interest to improve its formability; however, the effect warm forming may have on the coarsening of precipitates and the mechanical strength of these sheets has not been well studied. In this research, the coarsening behavior of AA6013-T6 precipitates has been explored, in the temperature range of 200-300 °C, and time of 30 s up to 50 h. Additionally, the effect of warm deformation on coarsening behavior was explored using: (1) simulated warm forming tests in a Gleeble thermo-mechanical simulator and (2) bi-axial warm deformation tests. Using a strong obstacle model to describe the yield strength (YS) evolution of the AA6013-T6 material, and a Lifshitz, Slyozov, and Wagner (LSW) particle coarsening law to describe the change in precipitate size with time, the coarsening kinetics were modeled for this alloy. The coarsening kinetics in the range of 220-300 °C followed a trend similar to that previously found for AA6111 for the 180-220 °C range. There was strong evidence that coarsening kinetics were not altered due to warm deformation above 220 °C. For warm forming between 200 and 220 °C, the YS of the AA6013-T6 material increased slightly, which could be attributed to strain hardening during warm deformation. Finally, a non-isothermal coarsening model was used to assess the potential reduction in the YS of AA6013-T6 for practical processing conditions related to auto-body manufacturing. The model calculations showed that 90% of the original AA6013-T6 YS could be maintained, for warm forming temperatures up to 280 °C, if the heating schedule used to get the part to the warm forming temperature was limited to 1 min.

Similar content being viewed by others

References

P.K. Mallick, Ed., Materials, Design and Manufacturing for Lightweight Vehicles, Elsevier, Amsterdam, 2010

A. Burnham, Updated Vehicle Specifications in the GREET Vehicle-Cycle Model. Argonne National Laboratory, 2012.

S.S. Hecker, Formability of Aluminum Alloy Sheets, J. Eng. Mater. Technol., 1975, 97, p 66–73

F. Shehata, M.J. Painter, and R. Pearce, The Warm Forming of Aluminium/Magnesium Alloy Sheet, J. Mech. Work. Technol., 1978, 2, p 279–290

R.A. Ayres, H.W. Lanning, B. Taylor, R. Heimbuch, and W.G. Brazier, Warm Forming the GM V-6 Oil Pan in Aluminum, No. 780180. SAE Technical Paper, 1978

R. Bagheriasl and M.J. Worswick, Formability of AA3003 Brazing Sheet at Elevated Temperatures: Limiting Dome Height Experiments and Determination of Forming Limit Diagrams, Int. J. Mater. Form., 2015, 8, p 229–244

G. Kamyar, R. Bagheriasl, and M.J. Worswick, Analysis of Nonisothermal Deep Drawing of Aluminum Alloy Sheet with Induced Anisotropy and Rate Sensitivity at Elevated Temperatures, J. Manuf. Sci. Eng., 2014, 136(011006–1), p 16

W.S. Miller, L. Zhaung, J. Bottema et al., Recent Development in Aluminium Alloys for the Automotive Industry, Mater. Sci. Eng. A, 2000, 280A, p 37–49

D. Li and A.K. Ghosh, Tensile Deformation Behavior of Aluminum Alloys at Warm Forming Temperatures, Mater. Sci. Eng. A, 2003, 352A, p 279–286

D. Li and A.K. Ghosh, Biaxial Warm Forming Behavior of Aluminum Sheet Alloys, J. Mater. Process. Technol., 2004, 145, p 281–293

S. Dicecco, C. Butcher, and M.J. Worswick, et al., Determination of Forming Limit Diagrams of AA6013-T6 Aluminum Alloy Sheet Using a Time and Position Dependent Localized Necking Criterion, Proceedings International Deep Drawing Research Group, IDDRG, Linz, Austria, June 12-15, 2016

P.E. Krajewski, The Warm Ductility of Commercial Aluminum Alloy Sheets, No. 2005-01-1388. SAE Technical Paper, 2005

S. Esmaeili, D.J. Lloyd, and W.J. Poole, A Yield Strength Model for the Al-Mg-Si-Cu Alloy AA6111, Acta Mater., 2003, 51, p 2243–2257

S. Esmaeili, X. Wang, D.J. Lloyd, and W.J. Poole, On the Precipitation-Hardening Behavior of the Al-Mg-Si-Cu Alloy AA6111, Metall. Mater. Trans. B, 2003, 34A, p 751–763

S. Esmaeili and D.J. Lloyd, Effect of Composition on Clustering Reactions in AlMgSi (Cu) Alloys, Scr. Mater., 2004, 50, p 155–158

S. Esmaeili, D. Vaumousse, M. Zandbergen et al., A Study on the Early-Stage Decomposition in the Al-Mg-Si-Cu Alloy AA6111 by Electrical Resistivity and Three-Dimensional Atom Probe, Philos. Mag., 2007, 87, p 3797–3816

S. Pogatscher, H. Antrekowitsch, H. Leitner et al., Influence of the Thermal Route on the Peak-Aged Microstructures in an Al-Mg-Si Aluminum Alloy, Scr. Mater., 2013, 68, p 158–161

M. Liu, B. Klobes, and K. Maier, On the Age-Hardening of an Al-Zn-Mg-Cu Alloy: A Vacancy Perspective, Scr. Mater., 2011, 64, p 21–24

S. Esmaeili, D.J. Lloyd, and W.J. Poole, Modeling of Precipitation Hardening for the Naturally Aged Al-Mg-Si-Cu Alloy AA6111, Acta Mater., 2003, 51, p 3467–3481

X. Wang, S. Esmaeili, and D.J. Lloyd, The Sequence of Precipitation in the Al-Mg-Si-Cu Alloy AA6111, Metall. Mater. Trans. A, 2006, 37A, p 2691–2699

S. Esmaeili and D.J. Lloyd, Modeling of Precipitation Hardening in Pre-aged AlMgSi (Cu) Alloys, Acta Mater., 2005, 53, p 5257–5271

S. Esmaeili, D.J. Lloyd, and W.J. Poole, Effect of Natural Aging on the Resistivity Evolution During Artificial Aging of the Aluminum Alloy AA6111, Mater. Lett., 2005, 59, p 575–577

S. Esmaeili and D.J. Lloyd, The Role of Copper in the Precipitation Kinetics of 6000 Series Al Alloys, Mater. Sci. Forum, 2006, 519–521, p 169–176

D. Bryant, The Effects of Preaging Treatments on Aging Kinetics and Mechanical Properties in AA6111 Aluminum Autobody Sheet, Metall. Mater. Trans. A, 1999, 30A, p 1999–2006

S. Esmaeili and D.J. Lloyd, Characterization of the Evolution of the Volume Fraction of Precipitates in Aged AlMgSiCu Alloys Using DSC Technique, Mater. Charact., 2005, 55, p 307–319

W.A. Johnson and R.F. Mehl, Reaction Kinetics in Process of Nucleation and Growth, Trans AIME, 1939, 135, p 396–415

M. Avrami, Kinetics of Phase Change. I, General Theory, J. Chem. Phys., 1939, 7, p 1103–1112

A.N. Kolmogorov, On the Statistical Theory of the Crystallization of Metals, Bull. Acad. Sci. USSR Math. Ser., 1937, 1, p 355–359

I.M. Lifshitz and V.V. Slyozov, The Kinetics of Precipitation from Supersaturated Solid Solutions, Phys. Stat. Sol., 1961, 19, p 35–50

C.Z. Wagner, Theory of Precipitate Change by Redissolution, Z. Elektrochem., 1961, 65, p 581–591

M. Kolar, K.O. Pedersen, S. Gulbrandsen-Dahl et al., Effect of Pre-deformation on Mechanical Response of an Artificially Aged Al-Mg-Si Alloy, Mater. Trans., 2011, 52, p 1356–1362

K. Teichmann, C.D. Marioara, K.O. Pedersen et al., The Effect of Simultaneous Deformation and Annealing on the Precipitation Behaviour and Mechanical Properties of an Al-Mg-Si Alloy, Mater. Sci. Eng. A, 2003, 565A, p 228–235

R.S. Yassar, D.P. Field, and H. Weiland, The Effect of Predeformation on the β ″and β′ Precipitates and the Role of Q′ Phase in an Al-Mg-Si Alloy; AA6022, Scr. Mater., 2005, 53, p 299–303

R.S. Yassar, D.P. Field, and H. Weiland, The Effect of Cold Deformation on the Kinetics of the β″ Precipitates in an Al-Mg-Si Alloy, Metall. Mater. Trans. A, 2005, 36A, p 2059–2065

ASTM Standard E1097-12, Standard Guide for Determination of Various Elements by Direct Current Plasma Atomic Emission Spectrometry. ASTM International, 2012

ASTM Standard E8/E8M-11, Standard Test Methods for Tension Testing of Metallic Materials. ASTM International, 2011

H.L. Trajano, J.D. DeMartini, M.H. Studer, and C.E. Wyman, Comparison of the Effectiveness of a Fluidized Sand Bath and a Steam Chamber for Reactor Heating, Ind. Eng. Chem. Res., 2013, 52, p 4932–4938

H.R. Shercliff and M.F. Ashby, A Process Model for Age Hardening of Aluminium Alloys—II. Applications of the Model, Acta Metall. Mater., 1990, 38, p 1803–1812

J. Go, Modelling the Interaction Between Recovery, Recrystallization and Precipitation in AA6111. University of British Columbia Ph.D. Thesis, Vancouver, Canada, 2006.

T.L. Bergman, F.P. Incropera, and A.S. Lavine, Fundamentals of Heat and Mass Transfer, Wiley, New York, 2011

Acknowledgments

The authors would like to acknowledge funding and materials provided by: Honda, Arconic, Promatek, the Natural Sciences and Engineering Research Council of Canada (NSERC) and the Canada Research Chairs Secretariat.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Di Ciano, M., DiCecco, S., Esmaeili, S. et al. Coarsening of AA6013-T6 Precipitates During Sheet Warm Forming Applications. J. of Materi Eng and Perform 27, 939–947 (2018). https://doi.org/10.1007/s11665-018-3161-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3161-9