Abstract

The solution heat treatment (SHT) is an important step in hot forming and in-die quenching (HFQ) process. Herein, the SHT of cold-rolled AA7075-H18 alloy sheets is carried out in the temperature range of 462-518 °C for 0.9-29 min, and a response surface model based on strength and toughness is established. The results reveal that the maximal strength and toughness are achieved after SHT at 490.3 °C for 19.1 min and 475.1 °C for 21.1 min, respectively. One should note that the mechanical properties are closely related to the microstructural evolution during the SHT process. In particular, the dissolution amount of MgZn2 particles increases with the increase of SHT temperature or time, which further increases the strength of AA7075 alloy after age-hardening treatment. However, the alloy is overheated when the solution temperature is close to 510 °C, which deteriorates its strength and toughness. On the other hand, the cold-rolled texture is disappeared after the SHT process and a random recrystallization orientation is formed. Moreover, an excellent consistency between the variation trend of recrystallized grains and the response surface model is obtained, confirming that the response surface model is reliable. The experimental results show that the mechanical properties under different SHT process conditions depend on the coupling effect of precipitation strengthening and grain size strengthening. Finally, the process windows for optimizing the SHT process to balance the strength and toughness of sheets are defined. The current research provides crucial theoretical support and systematic guidance for the manufacturing of hot-formed AA7075 alloy components.

Similar content being viewed by others

References

P. Bamberg, G. Gintrowski, Z. Liang, A. Schiebahn, U. Reisgen, N. Precoma and C. Geffers, Development of a New Approach to Resistance Spot Weld AW-7075 Aluminum Alloys for Structural Applications: an Experimental Study-Part 1, J. Mater. Res. Technol., 2021, 15, p 5569`5581.

K. Omer, A. Abolhasani, S. Kim, T. Nikdejad, C. Butcher, M. Wells, S. Esmaeili and M. Worswick, Process Parameters for Hot Stamping of AA7075 and D-7xxx to Achieve High Performance Aged Products, J. Mater. Process. Technol., 2018, 257, p 170–179.

M. Yu, Y. Zhang, X. Li, K. Wen, B. Xiong, Z. Li, L. Yan, H. Yan, H. Liu and Y. Li, Effect of Recrystallization on Plasticity, Fracture Toughness and Stress Corrosion Cracking of a High-Alloying Al-Zn-Mg-Cu Alloy, Mater. Lett., 2020, 275, p 128074.

W.S. Miller, L. Zhuang, J. Bottema, A.J. Wittebrood, P. De Smet, A. Vieregge and A. Haszler, Recent Development in Aluminium Alloys for the Automotive Industry, Mater. Sci. Eng. A, 2000, 280(1), p 37–49.

J. Lin, T. A. Dean, R. P. Garrett, A. Foster, Process for Forming Metal Alloy Sheet Components. WO 2008/059242 A2, Int. patent (2008).

Y. Liu, Z. Zhu, Z. Wang, B. Zhu, Y. Wang and Y. Zhang, Formability and Lubrication of a B-Pillar in Hot Stamping with 6061 and 7075 Aluminum Alloy Sheets, Procedia. Eng., 2017, 207, p 723–728.

N.R. Harrison and S.G. Luckey, Hot Stamping of a B-Pillar Outer from High Strength Aluminum Sheet AA7075, SAE Int. J. Mater. Manuf., 2014, 7(3), p 567–573.

P.A. Rometsch, Y. Zhang and S. Knight, Heat Treatment of 7xxx Series Aluminium Alloys-Some Recent Developments, Trans. Nonferr. Metal. Soc., 2014, 24(7), p 2003–2017.

K. Chen, H. Liu, Z. Zhang, S. Li and R.I. Todd, The Improvement of Constituent Dissolution and Mechanical Properties of 7055 Aluminum Alloy by Stepped Heat Treatments, J. Mater. Process. Technol., 2003, 142(1), p 190–196.

D.K. Xu, P.A. Rometsch and N. Birbilis, Improved Solution Treatment for an As-Rolled Al-Zn-Mg-Cu Alloy. Part I. Characterisation of Constituent Particles and Overheating, Mater. Sci. Eng. A, 2012, 534, p 234–243.

G. Chen, L. Chen, G. Zhao and C. Zhang, Microstructure Evolution During Solution Treatment of Extruded Al-Zn-Mg Profile Containing a Longitudinal Weld Seam, J. Alloy. Compd., 2017, 729, p 210–221.

L. Chen, Y. Li, J. Tang, G. Zhao and C. Zhang, Investigation on Microstructure and Mechanical Properties of Al-5.50Zn-2.35Mg-1.36Cu Alloy Fabricated by Hot Extrusion Process, J. Mater. Res., 2019, 34(18), p 3151–3162.

A.R. Eivani, H. Ahmed, J. Zhou and J. Duszczyk, Correlation Between Electrical Resistivity, Particle Dissolution, Precipitation of Dispersoids, and Recrystallization Behavior of AA7020 Aluminum Alloy, Metall. Mater. Trans. A, 2009, 40, p 2435–2446.

G. Liu, G.J. Zhang, X.D. Ding, J. Sun and K.H. Chen, Dependence of Fracture Toughness on Multiscale Second Phase Particles in High Strength Al Alloys, Mater. Sci. Technol., 2013, 19(7), p 887–896.

D.K. Xu, P.A. Rometsch and N. Birbilis, Improved Solution Treatment for an As-Rolled Al-Zn-Mg-Cu Alloy. Part II. Microstructure and Mechanical Properties, Mater. Sci. Eng. A, 2012, 534, p 244–252.

S.M. Ashrafizadeh and A.R. Eivani, Correlative Evolution of Microstructure, Particle Dissolution, Hardness and Strength of Ultrafine Grained AA6063 Alloy During Annealing, Mater. Sci. Eng. A, 2015, 644, p 284–296.

S.M. Ashrafizadeh, A.R. Eivani, H.R. Jafarian and J. Zhou, Improvement of Mechanical Properties of AA6063 Aluminum Alloy After Equal Channel Angular Pressing by Applying a Two-Stage Solution Treatment, Mater. Sci. Eng. A, 2017, 687, p 54–62.

H.K. Kim, H.W. Kim, J.H. Cho and J.C. Lee, High-Formability Al Alloy Sheet Produced by Asymmetric Rolling of Strip-Cast Sheet, Mater. Sci. Eng. A, 2013, 574, p 31–36.

A. Baghbani Barenji, A.R. Eivani, M. Hasheminiasari, H.R. Jafarian and N. Park, Effects of Hot Forming Cold Die Quenching and Inter-Pass Solution Treatment on the Evolution of Microstructure and Mechanical Properties of AA2024 Aluminum Alloy After Equal Channel Angular Pressing, J. Mater. Res. Technol., 2020, 9(2), p 1683–1697.

A. Baghbani Barenji, A.R. Eivani, H.R. Jafarian and N. Park, Effects of Hot Forming Cold Die Quenching and Solution Treatment on Formability and Pressing Load During Equal Channel Angular Deformation of AA2024 Aluminum Alloy, J. Mater. Res. Technol., 2020, 9(3), p 5599–5609.

J. Hu, K. Ikeda and T. Murakami, Effect of Texture Components on Plastic Anisotropy and Formability of Aluminium Alloy Sheets, J. Mater. Process. Technol., 1998, 73(1–3), p 49–56.

T. Leffers and R.K. Ray, The Brass-Type Texture and Its Deviation from the Copper-Type Texture, Prog. Mater. Sci., 2009, 54(3), p 351–396.

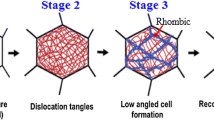

T. Sakai, A. Belyakov, R. Kaibyshev, H. Miura and J.J. Jonas, Dynamic and Post-Dynamic Recrystallization Under Hot, Cold and Severe Plastic Deformation Conditions, Prog. Mater. Sci., 2014, 60, p 130–207.

J. Hjelen, R. Ørsund and E. Nes, On the Origin of Recrystallization Textures in Aluminium, Acta Metall. Mater., 1991, 39(7), p 1377–1404.

A.W. Bowen, Texture Development in High Strength Aluminium Alloys, Mater. Sci. Technol., 1990, 6(11), p 1058–1071.

A. Saai, S. Dumoulin, O.S. Hopperstad and O.G. Lademo, Simulation of Yield Surfaces for Aluminium Sheets with Rolling and Recrystallization Textures, Comp. Mater. Sci., 2013, 67, p 424–433.

C. Schäfer and G. Gottstein, The Origin and Development of the P{011}<111> Orientation During Recrystallization of Particle-Containing Alloys, Int. J. Mater. Res., 2011, 102(9), p 1106–1114.

K.F. Adam, Z. Long and D.P. Field, Analysis of Particle-Stimulated Nucleation (PSN)-Dominated Recrystallization for Hot-Rolled 7050 Aluminum Alloy, Metall. Mater. Trans. A, 2017, 48(4), p 2062–2076.

R. Boulis, S. DiCecco and M.J. Worswick, Die Quench Process Sensitivity of AA7050, IOP Conf. Ser. Mater. Sci. Eng., 2019, 651(1), p 012106.

Z. Zhang, J. Yu and D. He, Influence of Contact Solid-Solution Treatment on Microstructures and Mechanical Properties of 7075 Aluminum Alloy, Mater. Sci. Eng. A, 2019, 743, p 500–503.

Y. Liu, B. Zhu, Y. Wang, S. Li and Y. Zhang, Fast Solution Heat Treatment of High Strength Aluminum Alloy Sheets in Radiant Heating Furnace During Hot Stamping, Int. J. Light. Mater. Manuf., 2020, 3(1), p 20–25.

B.B. He, B. Hu, H.W. Yen, G.J. Cheng, Z.K. Wang, H.W. Luo and M.X. Huang, High Dislocation Density-Induced Large Ductility in Deformed and Partitioned Steels, Science, 2017, 357(6355), p 1029–1032.

X. Zhang, T. Chen, S. Ma, H. Qin and J. Ma, Overcoming the Strength-Ductility Trade-Off of an Aluminum Matrix Composite by Novel Core-Shell Structured Reinforcing Particulates, Compos. Part B Eng., 2021, 206, p 108541.

S. Ghosh and S. Mula, Fracture Toughness Characteristics of Ultrafine Grained Nb–Ti Stabilized Microalloyed and Interstitial Free Steels Processed by Advanced Multiphase Control Rolling, Mater. Charact., 2020, 159, p 110003.

S. Ghosh and S. Mula, Improvement of Fracture Toughness of Ti+Nb Stabilized Microalloyed and Interstitial Free Steels Processed Through Single Phase Regime Control Multiaxial Forging, Mater. Sci. Eng. A, 2020, 772, p 138817.

G. Kumar, S. Ghosh, S. Pallaspuro, M.C. Somani, J. Kömi, S.K. Mishra and A.A. Gokhale, Fracture Toughness Characteristics of Thermo-Mechanically Rolled Direct Quenched and Partitioned Steels, Mater. Sci. Eng. A, 2020, 840, p 142788.

Z. Wang, Z.H. Cao, J.F. Wang and M.X. Huang, Improving the Bending Toughness of Al-Si Coated Press-Hardened Steel by Tailoring Coating Thickness, Scr. Mater., 2021, 1922, p 19–25.

Plate bending test for metallic materials, VDA238–100, German Association of the Automotive Industry (2010).

R. Garrett, J. Lin and T.A. Dean, An Investigation of the Effects of Solution Heat Treatment on Mechanical Properties for AA 6xxx Alloys: Experimentation and Modelling, Int. J. Plast., 2005, 21(8), p 1640–1657.

G. Wang, Z. Gu, G. Yu and X. Li, Precipitates Evolution of the AA7075-H18 Alloy Sheet During the Application of the Solution Heat Treatment Process, Mater. Lett., 2022, 318, p 132230.

Metallic materials -Tensile testing-Part 1: Method of test at room temperature, ISO 6892–1, International Organization for Standardization (2019)

G.E.P. Box and K.B. Wilson, On the Experimental Attainment of Optimum Conditions, J. R. Stat. Soc. B., 1951, 13(1), p 1–38.

J. Gjønnes, J. Chr and Simensen, An Electron Microscope Investigation of the Microstructure in an Aluminium-Zinc-Magnesium Alloy, Acta. Mater., 1970, 18, p 881–890.

M. Dumont, W. Lefebvre, B. Doisneau-Cottignies and A. Deschamps, Characterisation of the Composition and Volume Fraction of η′ and η Precipitates in an Al-Zn-Mg Alloy by a Combination of Atom Probe, Small-Angle X-ray Scattering and Transmission Electron Microscopy, Acta. Mater., 2005, 53, p 2881–2892.

A.K. Singh, S. Ghosh and S. Mula, Simultaneous Improvement of Strength, Ductility and Corrosion Resistance of Al2024 Alloy Processed by Cryoforging Followed by Ageing, Mater. Sci. Eng. A, 2016, 651, p 774–785.

F.J. Humphreys, W.S. Miller and M.R. Djazeb, Microstructural Development During Thermomechanical Processing of Particulate Metal-Matrix Composites, Mater. Sci. Technol., 2013, 6(11), p 1157–1166.

X.Y. Wang, J.T. Jiang, G.A. Li, X.M. Wang, W.Z. Shao and L. Zhen, Particle-Stimulated Nucleation and Recrystallization Texture Initiated by Coarsened Al2CuLi Phase in Al-Cu-Li Alloy, J. Mater. Res. Technol., 2021, 10, p 643–650.

S. Ghosh, N. Bibhanshu, S. Suwas and K. Chatterjee, Surface Mechanical Attrition Treatment of Additively Manufactured 316L Stainless Steel Yields Gradient Nanostructure with Superior Strength and Ductility, Mater. Sci. Eng. A, 2021, 820, p 141541.

S. Ghosh, A.K. Singh and S. Mula, Effect of Critical Temperatures on Microstructures and Mechanical Properties of Nb-Ti Stabilized IF Steel Processed by Multiaxial Forging, Mater. Des., 2016, 100, p 47–57.

A. Hamada, A. Khosravifard, S. Ghosh, M. Jaskari, A. Järvenpää and P. Karjalainen, High-Speed Erichsen Testing of Grain-Refined 301LN Austenitic Stainless Steel Processed by Double-Reversion Annealing, Metall. Mater. Trans. A, 2022, 53, p 2174–2194.

Acknowledgments

This work was funded by the Technology Development Program of Jilin Province (20210201038GX). The authors are grateful to FAW Tooling Die Manufacturing Co., Ltd., for their valuable help in this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, G., Li, X., Yu, G. et al. Optimization of Solution Heat Treatment Processes for AA7075-H18 Alloy Sheets. J. of Materi Eng and Perform 32, 9614–9626 (2023). https://doi.org/10.1007/s11665-023-07818-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-07818-4