Abstract

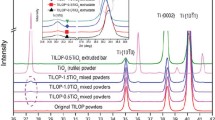

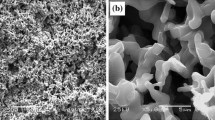

A new simple powder metallurgy process by sintering TiH2 powders was used to manufacture porous Ti components. The effects of the processing parameters (pressure of cold isostatic pressing and sintering temperature) and the TiH2/Ti ratio in the powder mixtures on the impurities, the linear shrinkage and the pore properties (including overall and open porosities) were comprehensively determined. The addition of TiH2 as a reactant has been found beneficial for the synthesis of porous Ti components. The formation mechanisms of pores were demonstrated based on the dehydrogenation process of TiH2 during sintering, resulting in highest reactivity due to the “in statu nascendi” generation of the metal. In addition, the hardness and corrosion resistance of all the sintered samples were evaluated, related to the overall and open porosities. As a result, an optimal composition of Ti-40 wt.% TiH2 was defined, as its maximum open porosity was about 23%.

Reprinted from Peng et al. (Ref 27). Copyright (2016), with permission from Elsevier

Similar content being viewed by others

References

Q. Xu, Synthesis, Microstructure and Mechanical Properties of Titanium with Controlled Levels of Porosity, University of Waikato, Hamilton, 2014

V.V. Savich, Porous Materials from Titanium Powders: Past, Present, and Future, Powder Metall. Met. Ceram., 2014, 52(11), p 632–643

Eaton Corporation, Titanium Porous Metal Technology Filter Cartridges 2017 [cited 2017 26 February]. http://www.eaton.eu/PL/Eaton/ProductsServices/Filtration/BagandCartridgeFiltration/Industrial-Process/Industrial-Depth-Filter-Cartridges/LOFMET/index.htm

O.M. Ivasishin, V. Anokhin, A. Demidik, and D.G. Savvakin, Cost-Effective Blended Elemental Powder Metallurgy of Titanium Alloys for Transportation Application, Key Eng. Mater., 2000, 188, p 55–62

O. Ivasishin, V. Moxson, M. Qian, and H. Froes, Low-Cost Titanium Hydride Powder Metallurgy, Titanium Powder Metallurgy: Science, Technology and Applications, Q. Ma and F.H. Froes, Ed., Butterworth-Heinemann, London, 2015, p 117–148

V.V. Joshi, C. Lavender, V. Moxon, V. Duz, E. Nyberg, and K.S. Weil, Development of Ti-6Al-4V and Ti-1Al-8V-5Fe Alloys Using Low-Cost TiH2 Powder Feedstock, J. Mater. Eng. Perform., 2012, 22(4), p 995–1003

J. Oh, K. Heo, W. Kim, G. Choi, and J. Lim, Sintering Properties of Ti-6Al-4V Alloys Prepared Using Ti/TiH2 Powders, Mater. Trans., 2013, 54(1), p 119–121

V. Macin and H.J. Christ, Influence of Hydride-Induced Microstructure Modification on Mechanical Properties of Metastable Beta Titanium Alloy Ti 10V-2Fe-3Al, Int. J. Hydrog. Energy, 2015, 40(47), p 16878–16891

B. Sharma, S.K. Vajpai, and K. Ameyama, Microstructure and Properties of Beta Ti-Nb Alloy Prepared by Powder Metallurgy Route Using Titanium Hydride Powder, J. Alloys Compd., 2016, 656, p 978–986

A.R. Kennedy and V.H. Lopez, The Decomposition Behavior of as-Received and Oxidized TiH2 Foaming-Agent Powder, Mater. Sci. Eng. A, 2003, 357(1–2), p 258–263

H.R.Z. Sandim, B.V. Morante, and P.A. Suzuki, Kinetics of Thermal Decomposition of Titanium Hydride Powder Using In Situ High-Temperature X-ray Diffraction (HTXRD), Mater. Res., 2005, 8(3), p 293–297

B. Matijasevic-Lux, J. Banhart, S. Fiechter, O. Görke, and N. Wanderka, Modification of Titanium Hydride for Improved Aluminium Foam Manufacture, Acta Mater., 2006, 54(7), p 1887–1900

B. Neirinck, J. Fransaer, O. Van der Biest, J. Vleugels, Slip Casting of Titanium and Titanium Hydride Stabilized Emulsions for the Production of Porous Bulk Titanium, in Proceedings of the EuroPM 2009 Powder Metallurgy Congress & Exhibition (2009)

Y. Zhao, M. Taya, Processing of Porous NiTi by Spark Plasma Sintering Method, in Smart Structures and Materials (International Society for Optics and Photonics, 2006)

Y.W. Gu, M.S. Yong, B.Y. Tay, and C.S. Lim, Synthesis and Bioactivity of Porous Ti Alloy Prepared by Foaming with TiH2, Mater. Sci. Eng. C, 2009, 29(5), p 1515–1520

S. Wu, X. Liu, K.W. Yeung, T. Hu, Z. Xu, J.C. Chung, and P.K. Chu, Hydrogen Release from Titanium Hydride in Foaming of Orthopedic NiTi Scaffolds, Acta Biomater., 2011, 7(3), p 1387–1397

V. Duz, O. Ivasishin, C. Lavender, V. Moxson, V. Telin, Innovative Powder Metallurgy Process for Producing Low Cost Titanium and Titanium and Titanium Alloy Components, in 24th Annual ITA Conference & Exhibition (Las Vegas, Nevada, USA, 2008)

C.R.F. Azevedo, D. Rodrigues, and F.B. Neto, Ti-Al-V Powder Metallurgy (PM) Via the Hydrogenation–Dehydrogenation (HDH) Process, J. Alloys Compd., 2003, 353(1–2), p 217–227

Z.S. Rak and J. Walter, Porous Titanium Foil by Tape Casting Technique, J. Mater. Process. Technol., 2006, 175(1–3), p 358–363

H.T. Wang, M. Lefler, Z.Z. Fang, T. Lei, S.M. Fang, J.M. Zhang, and Q. Zhao, Titanium and Titanium Alloy Via Sintering of TiH2, Key Eng. Mater., 2010, 436, p 157–163

K.S. Weil, E.A. Nyberg, and K.L. Simmons, Use of a Naphthalene-Based Binder in Injection Molding Net-Shape Titanium Components of Controlled Porosity, Mater. Trans., 2005, 46(7), p 1525–1531

D.-W. Lee, H.-S. Lee, J.-H. Park, S.-M. Shin, and J.-P. Wang, Sintering of Titanium Hydride Powder Compaction, Procedia Manuf., 2015, 2, p 550–557

Q. Ye, Z.-M. Guo, J.-L. Bai, B.-X. Lu, J.-P. Lin, J.-J. Hao, J. Luo, and H.-P. Shao, Gelcasting of Titanium Hydride to Fabricate Low-Cost Titanium, Rare Met., 2015, 34(5), p 351–356

C. Wang, L. Pan, Y. Zhang, S. Xiao, and Y. Chen, Deoxidization Mechanism of Hydrogen in TiH2 Dehydrogenation Process, Int. J. Hydrog. Energy, 2016, 41(33), p 14836–14841

S.-W. Yook, B.-H. Yoon, H.-E. Kim, Y.-H. Koh, and Y.-S. Kim, Porous Titanium (Ti) Scaffolds by Freezing TiH2/Camphene Slurries, Mater. Lett., 2008, 62(30), p 4506–4508

A. Ibrahim, F. Zhang, E. Otterstein, and E. Burkel, Processing of Porous Ti and Ti5Mn Foams by Spark Plasma Sintering, Mater. Des., 2011, 32(1), p 146–153

Q. Peng, B. Yang, L. Liu, C. Song, and B. Friedrich, Porous TiAl Alloys Fabricated by Sintering of TiH2 and Al Powder Mixtures, J. Alloys Compd., 2016, 656, p 530–538

Q. Ma, Cold Compaction and Sintering of Titanium and Its Alloys for Near-Net-Shape or Preform Fabrication, Int. J. Powder Metall., 2010, 46(5), p 29–44

ISO 2738:1999, Sintered Metal Materials, Excluding Hardmetals—Permeable Sintered Metal Materials—Determination of Density, Oil Content and Open Porosity (International Organization for Standardization, Geneva)

H. Liu, P. He, J.C. Feng, and J. Cao, Kinetic Study on Nonisothermal Dehydrogenation of TiH2 Powders, Int. J. Hydrog. Energy, 2009, 34(7), p 3018–3025

E. Illeková, J. Harnúšková, R. Florek, F. Simančík, I. Maťko, and P. Švec, Peculiarities of TiH2 Decomposition, J. Therm. Anal. Calorim., 2010, 105(2), p 583–590

M. Ma, L. Liang, L. Wang, Y. Wang, Y. Cheng, B. Tang, W. Xiang, and X. Tan, Phase Transformations of Titanium Hydride in Thermal Desorption Process with Different Heating Rates, Int. J. Hydrog. Energy, 2015, 40(29), p 8926–8934

V. Bhosle, E. Baburaj, M. Miranova, and K. Salama, Dehydrogenation of TiH2, Mater. Sci. Eng. A, 2003, 356(1), p 190–199

K. Kawasaki, T. Sugita, and S. Ebisawa, Adsorption, Surface Reaction, and Mutual Displacement of CO, CO2 and O2 on Titanium Film, Surf. Sci., 1967, 7, p 502–506

K. Kawasaki, N. Hayashi, S. Ebisawa, and T. Sugita, Adsorption of CO, O2 and CO2 on Titanium Film by Electrical Conductivity Measurements, Jpn. J. Appl. Phys., 1971, 10(10), p 1359

S.W. Kim, H.-D. Jung, M.-H. Kang, H.-E. Kim, Y.-H. Koh, and Y. Estrin, Fabrication of Porous Titanium Scaffold with Controlled Porous Structure and Net-Shape Using Magnesium as Spacer, Mater. Sci. Eng. C, 2013, 33(5), p 2808–2815

J.-H. Lee, H.-E. Kim, K.-H. Shin, and Y.-H. Koh, Improving the Strength and Biocompatibility of Porous Titanium Scaffolds by Creating Elongated Pores Coated with a Bioactive, Nanoporous TiO2 Layer, Mater. Lett., 2010, 64(22), p 2526–2529

A. Zhecheva, W. Sha, S. Malinov, and A. Long, Enhancing the Microstructure and Properties of Titanium Alloys Through Nitriding and Other Surface Engineering Methods, Surf. Coat. Technol., 2005, 200(7), p 2192–2207

Alloy Phase Diagrams. Handbook, Aerospace Structural Metals, vol. 3 (ASM Int. Mater. Park, Ohio, 1992)

C. Jiménez, F. Garcia-Moreno, A. Rack, R. Tucoulou, M. Klaus, B. Pfretzschner, T. Rack, P. Cloetens, and J. Banhart, Partial Decomposition of TiH2 Studied In Situ by Energy-Dispersive Diffraction and Ex Situ by Diffraction Microtomography of Hard X-ray Synchrotron Radiation, Scr. Mater., 2012, 66(10), p 757–760

C. Jiménez, F. Garcia-Moreno, B. Pfretzschner, M. Klaus, M. Wollgarten, I. Zizak, G. Schumacher, M. Tovar, and J. Banhart, Decomposition of TiH2 Studied In Situ by Synchrotron X-ray and Neutron Diffraction, Acta Mater., 2011, 59(16), p 6318–6330

K. Asaoka, N. Kuwayama, O. Okuno, and I. Miura, Mechanical Properties and Biomechanical Compatibility of Porous Titanium for Dental Implants, J. Biomed. Mater. Res., 1985, 19(6), p 699–713

N. Tuncer, G. Arslan, E. Maire, and L. Salvo, Investigation of Spacer Size Effect on Architecture and Mechanical Properties of Porous Titanium, Mater. Sci. Eng. A, 2011, 530, p 633–642

H.H. Hausner and O.V. Roman, Linear Shrinkage of Metal Powder Compacts During Sintering, Sov. Powder Metall. Met. Ceram., 1965, 3(3), p 180–184

S.D. Luo, M. Yan, G.B. Schaffer, and M. Qian, Sintering of Titanium in Vacuum by Microwave Radiation, Metall. Mater. Trans. A, 2011, 42(8), p 2466–2474

T. Watanabe, The Sintering Phenomenon of Titanium Powders-A Discussion, Int. J. Powder Metall. Powder Technol., 1976, 12, p 209–214

A. Stuijts, Synthesis of Materials from Powders by Sintering, Annu. Rev. Mater. Sci., 1973, 3(1), p 363–395

H.E. Exner and G. Petzow, A Critical Assessment of Porosity Coarsening During Solid State Sintering, Adv. Sci. Technol., 2006, 45, p 539–548

H.E. Exner and C. Müller, Particle Rearrangement and Pore Space Coarsening During Solid-State Sintering, J. Am. Ceram. Soc., 2009, 92(7), p 1384–1390

R.L. Coble, Sintering Crystalline Solids. I. Intermediate and Final State Diffusion Models, J. Appl. Phys., 1961, 32(5), p 787–792

Magdalena. Dlapka, Herbert. Danninger, Chistian. Gierl, and Björn. Lindqvist, Defining the Pores in PM Components, Met. Powder Rep., 2010, 65(2), p 30–33

J. Breme, E. Eisenbarth, and V. Biehl, Titanium and its alloys for medical applications, Titanium and Titanium Alloys, C. Leyens and M. Peters, Ed., Wiley, New York, 2005, p 423–451

Y.-B.P. Kwan and J.R. Alcock, The Impact of Water Impregnation Method on the Accuracy of Open Porosity Measurements, J. Mater. Sci., 2002, 37, p 2557–2561

R. Machaka and H.K. Chikwanda, Analysis of the Cold Compaction Behavior of Titanium Powders: A Comprehensive Inter-Model Comparison Study of Compaction Equations, Metall. Mater. Trans. A, 2015, 46(9), p 4286–4297

J.M. Montes, J.A. Rodríguez, F.G. Cuevas, and J. Cintas, Consolidation by Electrical Resistance Sintering of Ti Powder, J. Mater. Sci., 2011, 46(15), p 5197–5207

J. Capek and D. Vojtech, Microstructural and Mechanical Characteristics of Porous Iron Prepared by Powder Metallurgy, Mater. Sci. Eng. C, 2014, 43, p 494–501

E. Baril, L. Lefebvre, and Y. Thomas, Interstitial Elements in Titanium Powder Metallurgy: Sources and Control, Powder Metall., 2011, 54(3), p 183–186

R.G. Neves, B. Ferrari, A.J. Sanchez-Herencia, and E. Gordo, Colloidal Approach for the Design of Ti Powders Sinterable at Low Temperature, Mater. Lett., 2013, 107, p 75–78

S. Ozbilen, D. Liebert, T. Beck, and M. Bram, Fatigue Behavior of Highly Porous Titanium Produced by Powder Metallurgy with Temporary Space Holders, Mater. Sci. Eng. C, 2016, 60, p 446–457

F.B. Mainier, L.P.C. Monteiro, S.S.M. Tavares, F.R. Leta, and J.M. Pardal, Evaluation of Titanium in Hydrochloric Acid Solutions Containing Corrosion Inhibitors, IOSR J. Mech. Civ. Eng., 2013, 10(1), p 66–69

Acknowledgments

Q.P. gratefully acknowledges the support from the China Scholarship Council (File No. 2011689004). The Authors acknowledge the help of T. Schreiner, RWTH Aachen University, with operating the CIP machine and the help of C. Song, Shanghai University, with XRD measurements. The authors thank A.M. Khamoushkoo, RWTH Aachen University, for designing the gas tight container for the sintering process.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Peng, Q., Yang, B. & Friedrich, B. Porous Titanium Parts Fabricated by Sintering of TiH2 and Ti Powder Mixtures. J. of Materi Eng and Perform 27, 228–242 (2018). https://doi.org/10.1007/s11665-017-3099-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-3099-3