Abstract

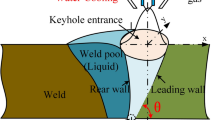

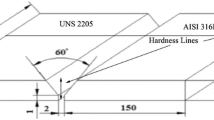

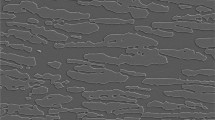

2205 duplex stainless steel (DSS) was welded by submerged arc welding. The effects of both heat input and groove type on the ferrite/austenite ratio and elemental diffusion of weld joints were investigated. The relationships among welding joint preparation, ferrite/austenite ratio, elemental diffusion, and pitting corrosion resistance of weld joints were analyzed. When the Ni content of the weld wire deposit was at minimum 2–4% higher than that of 2205 DSS base metal, the desired ratio of ferrite/austenite and elemental partitioning between the austenite and ferrite phases were obtained. While the pitting sensitivity of weld metal was higher than that of base metal, the self-healing capability of the passive film of weld metal was better than that of the base metal when a single V-type groove was used. Furthermore, the heat input should be carefully controlled since pitting corrosion occurred readily in the coarse-grained heat-affected zone near the fusion line of welded joints.

Similar content being viewed by others

References

F. Mirakhorli, F.M. Ghaini, and M.J. Torkamany, Development of Weld Metal Microstructures in Pulsed Laser Welding of Duplex Stainless Steel, J. Mater. Eng. Perform., 2012, 21, p 2173–2176

J. Luo, Y. Yuan, X. Wang, and Z. Yao, Double-Sided Single-Pass Submerged Arc Welding for 2205 Duplex Stainless Steel, J. Mater. Eng. Perform., 2013, 22, p 2477–2486

P. Bala Srinivasan, V. Muthupandi, V. Sivan, P. Bala Srinivasan, and W. Dietzel, Microstructure and Corrosion Behavior of Shielded Metal Arc-Welded Dissimilar Joints Comprising Duplex Stainless Steel and Low Alloy Steel, J. Mater. Eng. Perform., 2004, 15, p 758–764

H. Sieurin and R. Sandström, Austenite Reformation in the Heat-Affected Zone of Duplex Stainless Steel 2205, Mater. Sci. Eng., A, 2006, 18, p 250–256

H.C. Wu, L.W. Tsay, and C. Chen, Laser Beam Welding of 2205 Duplex Stainless Steel with Metal Powder Additions, ISIJ Int., 2004, 44, p 1720–1726

L. Duprez, B.C.D. Cooman, and N. Akdut, Microstructure Evolution During Isothermal Annealing of a Standard Duplex Stainless Steel Type 1.4462, Steel Res. Int., 2000, 71, p 417–422

C. Garcia, M.P.D. Tiedra, Y. Blanco, O. Martin, and F. Martin, Intergranular Corrosion of Welded Joints of Austenitic Stainless Steels Studied by Using an Electrochemical Minicell, Corros. Sci., 2008, 50, p 1184–1194

L. Karlsson, Intermetallic Phase Precipitation in Duplex Stainless Steel and Weld Metals, WRC Bull., 1999, 438, p 1–23

S.S.M. Tavares, J.M. Pardal, L.D. Lima, I.N. Bastos, A.M. Nascimento, and J.A.D. Souza, Characterization of Microstructure, Chemical Composition, Corrosion Resistance and Toughness of a Multipass Weld Joint of Superduplex Stainless Steel UNS S32750, Mater. Charact., 2007, 58, p 610–616

K. Shinozaki, L. Ke, and T.H. North, Hydrogen Cracking in Duplex Stainless Steel Weld Metal, Weld. J., 1992, 71, p 387–396

H. Hachemi, M. Azzaz, and M.E. Djeghlal, Influence of Temperature and Chloride Concentration on Passivation Mechanism and Corrosion of a DSS2209 Welded Joint, J. Mater. Eng. Perform., 2016, 25, p 4292–4302

Z.Q. Zhang, H.Y. Jing, L.Y. Xu, Y.D. Han, G.L. Li, and L. Zhao, Investigation on Microstructure and Impact Toughness of Different Zones in Duplex Stainless Steel Welding Joint, J. Mater. Eng. Perform., 2017, 26, p 134–150

F. Muhammad, A. Ahmad, A. Farooq, and W. Haider, Effect of Post-weld Heat Treatment on Mechanical and Electrochemical Properties of Gas Metal Arc-Welded 316L (X2CrNiMo 17-13-2) Stainless Steel, J. Mater. Eng. Perform., 2016, 25, p 4283–4291

Z. Sun, M. Kuo, I. Annergren, and D. Pan, Effect of Dual Torch Technique on Duplex Stainless Steel Welds, Mater. Sci. Eng., A, 2003, 356, p 274–282

V. Muthupandi, P.B. Srinivasan, V. Shankar, S.K. Seshadri, and S. Sundaresan, Effect of Nickel and Nitrogen Addition on the Microstructure and Mechanical Properties of Power Beam Processed Duplex Stainless Steel, Mater. Lett., 2005, 59, p 23

V. Muthupandi, P.B. Srinivasan, S.K. Seshadri, and S. Sundaresan, Effect of Weld Metal Chemistry and Heat Input on the Structure and Properties of Duplex Stainless Steel Welds, Mater. Sci. Eng., A, 2003, 358, p 9–16

E. Capello, P. Chiarello, B. Previtali, and M. Vedani, Laser Welding and Surface Treatment of a 22Cr-5M-3Mo Duplex Stainless Steel, Mater. Sci. Eng., A, 2003, 351, p 334–343

S.H. Wang, P.K. Chiu, J.R. Yang, and J. Fang, Gamma (γ) Phase Transformation in Pulsed GTAW Weld Metal of Duplex Stainless Steel, Mater. Sci. Eng., A, 2006, 420, p 26–33

J.D. Kordatos, G. Fourlaris, and G. Papadimitriou, The Effect of Cooling Rate on the Mechanical and Corrosion Properties of SAF2205 (UNS 31803) Duplex Stainless Steel Welds, Scripta Mater., 2001, 44, p 401–408

J.W. Elmer, T.A. Palmer, and E.D. Specht, Direct Observations of Sigma Phase Formation in Duplex Stainless Steels Using In-Situ, Synchrotron X-Ray Diffraction, Metall. Mater. Trans. A, 2007, 38, p 464–475

B. Deng, Y. Jiang, J. Gong, C. Zhong, J. Gao, and J. Li, Critical Pitting and Repassivation Temperatures for Duplex Stainless Steel in Chloride Solutions, Electrochim. Acta, 2008, 53, p 5220–5225

Acknowledgments

This work was supported by Funding of National Natural Science Foundation of China (Grant No. 51405208), the China Postdoctoral Science Foundation Funded Project (Grant No. 2016M601753), the Natural Science Foundation of the Jiangsu Higher Education Institutions of China (Grant No. 16KJB460007), the Open Research Fund of Provincial Key Laboratory of Advanced Welding Technology of Jiangsu University of Science and Technology (Grant No. JSAWT-14-03), and the Priority Academic Program Development of Jiangsu Higher Education Institutions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, M., Liu, F., Pu, J. et al. The Microstructure and Pitting Resistance of Weld Joints of 2205 Duplex Stainless Steel. J. of Materi Eng and Perform 26, 5341–5347 (2017). https://doi.org/10.1007/s11665-017-2976-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2976-0