Abstract

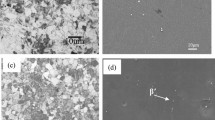

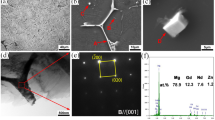

The principal purpose of this research was to evaluate the effects of Zr on the microstructure and thermal stability of an A357 alloy that has been subjected to an aging treatment (T6) and thermal exposure (250 °C). The results show that the addition of Zr had a significant influence on the refinement of the grain size, which enhanced the hardness and tensile strength of the A357 alloy under the T6 condition. During thermal exposure at 250 °C, the rodlike metastable β’-Mg2Si precipitates transformed into coarse equilibrium phase β-Mg2Si precipitates, resulting in a significant drop in the hardness and tensile strength of the T6 heat-treated A357 alloy. However, after thermal exposure, coherent, finely dispersed Al3Zr precipitates were found to be formed in the T6 heat-treated A357 alloy. The addition of 0.1% Zr played a critical role in improving the high-temperature strength. Consequently, the A357 alloy with the addition of Zr demonstrated better mechanical properties at room temperature and high temperature than the alloy without Zr, in terms of both microstructure and thermal stability.

Similar content being viewed by others

References

H. Ye, An Overview of the Development of Al-Si-Alloy Based Material for Engine Applications, J. Mater. Eng. Perform., 2003, 12, p 288–297

A.A. Canales, J.T. Silva, D. Gloria, S. Valtierra, and R. Colás, Thermal Analysis During Solidification of Cast Al-Si Alloys, Thermochim Acta, 2010, 510, p 82–87

Y.H. Tan, S.L. Lee, and Y.L. Lin, Effects of Be and Fe Content on Plane Strain Fracture Toughness in A357 Alloys, Metall. Mater. Trans. A, 1995, 26, p 2937–2945

Y.H. Tan, S.L. Lee, and Y.L. Lin, Effects of Be and Fe Additions on the Microstructure and Mechanical Properties of A357.0 Alloys, Metall. Mater. Trans. A, 1995, 26, p 1195–1205

A.M. Samuel, H.W. Doty, S. Valtierra, and F.H. Samuel, Relationship between Tensile and Impact Properties in Al-Si-Cu-Mg Cast Alloys and Their Fracture Mechanisms, Mater. Des., 2014, 53, p 938–946

T. Gao, X. Zhu, Q. Sun, and X. Liu, Morphological Evolution of ZrAlSi Phase and its Impact on the Elevated-temperature Properties of Al-Si Piston Alloy, J. Alloys Compd., 2013, 567, p 82–88

R. Mahmudi, P. Sepehrband, and H.M. Ghasemi, Improved Properties of A319 Aluminum Casting Alloy Modified with Zr, Mater. Lett., 2006, 60, p 2606–2610

M.F. Ibrahim, E. Samuel, A.M. Samuel, A.M.A.A. Ahmari, and F.H. Samuel, Impact Toughness and Fractography of Al-Si-Cu-Mg Base Alloys, Mater. Des., 2011, 32, p 3900–3910

C. Shi and X.G. Chen, Hot Workability and Processing Maps of 7150 Aluminum Alloys with Zr and V Additions, J. Mater. Eng. Perform., 2015, 24, p 2126–2139

J.D. Robson and P.B. Prangnell, Dispersoid Precipitation and Process Modelling in Zirconium Containing Commercial Aluminium Alloys, Acta Mater., 2001, 49, p 599–613

Y.V. Milman, A.I. Sirko, D.V. Lotsko, D.B. Miracle, and O.N. Senkov, Microstructure and Mechanical Properties of Cast and Wrought Al-Zn-Mg-Cu Alloys Modified with Zr and Sc, Mater. Sci. Forum, 2002, 396–402, p 1217–1222

B. Morere, R. Shahani, C. Maurice, and J. Driver, The Influence of Al3Zr Dispersoids on the Recrystallization of Hot-Deformed AA 7010 Alloys, Metall. Mater. Trans. A, 2001, 32, p 625–632

B. Baradarani and R. Raiszadeh, Precipitation Hardening of Cast Zr-containing A356 Aluminium Alloy, Mater. Des., 2011, 32, p 935–940

TRIMET Aluminium SE: Product-Information Trimal-37 (1/2016)

J. Hernandez-Sandoval, G.H.G. Elizondo, A.M. Samuel, S. Valtiierra, and F.H. Samuel, The Ambient and High Temperature Deformation Behavior of Al-Si-Cu-Mg Alloy with Minor Ti, Zr, Ni Additions, Mater. Des., 2014, 58, p 89–101

E. Sjolander and S. Seifeddine, The Heat Treatment of Al-Si-Cu-Mg Casting Alloys, J. Mater. Process. Technol., 2010, 210, p 1249–1259

G. Edwards, K. Stiller, G. Dunlop, and M. Couper, The Precipitation Sequence in Al-Mg-Si Alloys, Acta Mater., 1998, 46(11), p 3893–3904

K.E. Knipling, D.C. Dunand, and D.N. Seidman, Precipitation Evolution in Al-Zr and Al-Zr-Ti Alloys During Isothermal Aging at 375–425 °C, Acta Mater., 2008, 56(1), p 114–127

S.F. Fang, M.P. Wang, and M. Song, An Approach for the Aging Process Optimization of Al-Zn-Mg-Cu Series Alloys, Mater. Des., 2009, 30, p 2460–2467

C.T. Wu, S.L. Lee, M.H. Hsieh, and J.C. Lin, Effects of Cu content on Microstructure and Mechanical Properties of Al-14.5Si-0.5Mg Alloy, Mater. Charact., 2010, 61, p 1074–1079

M. Drouzy, S. Jacob, and M. Richard, Interpretation of Tensile Results by Means of Quality Index and Probable Yield Strength, AFS Int. Cast Metal., 1980, 5, p 43–50

Y. Haiyang, Y. Hongge, C. Jihua, S. Bin, Z. Yi, S. Yanjin, and M. Zhaojie, Effects of Minor Gd Addition on Microstructures and Mechanical Properties of the High Strain-Rate Rolled Mg-Zn-Zr alloys, J. Alloys Comp., 2014, 586, p 757–765

Acknowledgments

The authors gratefully acknowledge the financial support received from the National Chung-Shan Institute of Science and Technology under Contract No. NCSIST-1164-V102 (106).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tzeng, YC., Chengn, VS., Nieh, JK. et al. Microstructure and Thermal Stability of A357 Alloy With and Without the Addition of Zr. J. of Materi Eng and Perform 26, 5511–5518 (2017). https://doi.org/10.1007/s11665-017-2921-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2921-2