Abstract

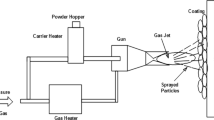

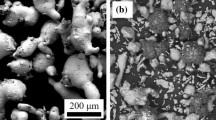

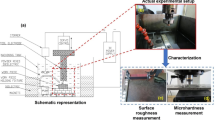

This study investigated the repulsive interaction of sulfide layers on compressor impeller blades remanufactured through plasma spray welding (PSW). Sulfide layers on the blades made of FV(520)B steel were prepared through multifarious corrosion experiments, and PSW was utilized to remanufacture blade specimens. The specimens were evaluated through optical microscopy, scanning electron microscopy, energy-dispersive spectroscopy, 3D surface topography, x-ray diffraction, ImageJ software analysis, Vicker’s micro-hardness test and tensile tests. Results showed a large number of sulfide inclusions in the fusion zone generated by sulfide layers embodied into the molten pool during PSW. These sulfide inclusions seriously degraded the mechanical performance of the blades remanufactured through PSW.

Similar content being viewed by others

References

S. Santo and M. Rameshni, The Challenges of Designing Grass Root Sulphur Recovery Units with a Wide Range of H2S Concentration from Natural Gas, J. Nat. Gas Sci. Eng., 2014, 18, p 137–148

Z.F. Yin, W.Z. Zhao, Z.Q. Bai, Y.R. Feng, and W.J. Zhou, Corrosion Behavior of SM 80SS Tube Steel in Stimulant Solution Containing H2S and CO2, Electrochim. Acta., 2008, 53(10), p p3690–p3700

W.F. Li, Y. Jun Zhou, and Y. Xue, Corrosion Behavior of 110S Tube Steel in Environments of High H2S and CO2 Content, J. Iron Steel Res. Int., 2012, 19(12), p 59–65

H. Yagi and J.B. Wagner, Chemical Diffusion and Electrical Conductivity of Ni3xS2, Oxid. Met., 1982, 18(1–2), p 41–54

W. Kai, T.W. Lee, and C.H. Wu, Sulfidation Behavior of Inconel 738 Superalloy at 500-900°C, Oxid. Met., 2001, 56(1-2), p 51–71

M. Matsumoto and Y. Umeda, An Analysis of Remanufacturing Practices in Japan, J. Remanuf., 2011, 1(1), p 2

S. Huang, D. Sun, and W. Wang, Microstructures and Properties of Ni Based Composite Coatings Prepared by Plasma Spray Welding with Mixed Powders, Int. J. Refract. Met. Hard Mater., 2015, 52, p 36–43

J.H. Hwang, M.S. Han, D.Y. Kim, and J.G. Youn, Tribological Behavior of Plasma Spray Coatings for Marine Diesel Engine Piston Ring and Cylinder Liner, J. Mater. Eng. Perform., 2006, 15(3), p 328–335

S. Huang, D. Sun, W. Wang, and H. Xu, Microstructures and Properties of In-situ TiC Particles Reinforced Ni-based Composite Coatings Prepared by Plasma Spray Welding, Ceram. Int., 2015, 241(9), p 12202–12210

K. Tanaka, Elastic/Plastic Indentation Hardness and Indentation Fracture Toughness: The Inclusion Core Model, J. Mater. Sci., 1987, 22(4), p 1501–1508

W. Sun, S. Nesic, and S. Papavinasam, Kinetics of Corrosion Layer Formation. Part 2-lron Sulfide and Mixed Iron Sulfide/Carbonate Layers in Carbon Dioxide/Hydrogen Sulfide Corrosion, Corrosion, 2008, 64(7), p 586–599

R.B. Alvarez, H.J. Martin, M.F. Horstemeyer, M.Q. Chandler, N. Williams, P.T. Wang, and A. Ruiz, Corrosion Relationships as a Function of Time and Surface Roughness on a Structural AE44 Magnesium Alloy, Corros. Sci., 2010, 52(5), p 1635–1648

Z. Liu, Y. Kobayashi, F. Yin, M. Kuwabara, and K. Nagai, Nucleation of Acicular Ferrite on Sulfide Inclusion during Rapid Solidification of Low Carbon Steel, ISIJ Int., 2007, 47(12), p 1781–1788

N.S. Cyril and A. Fatemi, Experimental Evaluation and Modeling of Sulfur Content and Anisotropy of Sulfide Inclusions on Fatigue Behavior of Steels, Int. J. Fatigue, 2009, 31(3), p p526–p537

Y. Kanbe, A. Karasev, H. Todoroki, and P.G. Jönsson, Analysis of Largest Sulfide Inclusions in Low Carbon Steel by Using Statistics of Extreme Values, Steel Res. Int., 2011, 82(4), p p313–p322

Y. Murakata, M.G. Sung, K. Sassa, and S. Asai, Visualization of Collision Behavior of Particles Simulating Inclusions in A Turbulent Molten Steel Flow and Its Theoretical Analysis, ISIJ Int., 2007, 47(5), p 633–637

D.J. Ha, H.K. Sung, J.W. Park, and S. Lee, Effects of Alloying Elements on Microstructure, Hardness, Wear Resistance, and Surface Roughness of Centrifugally Cast High-speed Steel Rolls, Metall. Mater. Trans. A Phys. Metall Mater. Sci., 2009, 40(11), p p2568–p2577

D.H. Jeong, U. Erb, K.T. Aust, and G. Palumbo, The Relationship Between Hardness and Abrasive Wear Resistance of Electrodeposited Nanocrystalline Ni-P Coatings, Scr. Mater., 2003, 48(8), p 1067–1072

K.T. Kim, S.I. Cha, and S.H. Hong, Hardness and Wear Resistance of Carbon Nanotube Reinforced Cu Matrix Nanocomposites, Mater. Sci. Eng. A., 2007, 449(12), p 46–50

D.H. Nam, J.H. Kim, S.I. Cha, S.I. Jung, J.K. Lee, H.M. Park, H.D. Park, and S.H. Hong, Hardness and Wear Resistance of Carbon Nanotube Reinforced Aluminum-Copper Matrix Composites, J. Nanosci. Nanotechnol., 2014, 14(12), p p9134–p9138

G. Tagliavia, M. Porfiri, and N. Gupta, Analysis of Hollow Inclusion-Matrix Debonding in Particulate Composites, Int. J. Solids Struct., 2010, 47(16), p 2164–2177

P.C. Savalia, H.V. Tippur, and M.S. Kirugulige, A Numerical Study of Inclusion-Matrix Debonding in the Presence of a Nearby Crack, Eng. Fract. Mech., 2008, 75(5), p p926–p942

Y.H. Zhao and G.J. Weng, A Theory of Inclusion Debonding and Its Influence on the Stress-Strain Relations of a Ductile Matrix Composite, Int. J. Damage Mech., 1995, 4(2), p 196–211

P.C. Savalia and H.V. Tippur, A Study of Crack-inclusion Interactions and Matrix-inclusion Debonding Using Moiré Interferometry and Finite Element Method, Exp. Mech., 2007, 47(4), p p533–p547

Q.H. Tang, D. Zhou, Y.L. Wang, and G.F. Liu, Laser Cleaning of Sulfide Scale on Compressor Impeller Blade, Appl. Surf. Sci., 2015, 355, p 334–340

Acknowledgments

This work was supported by Major State Basic Research Development Program of China (973 Program) (No. 2011CB013400). The authors acknowledge the help provided by the Experimental Center of Materials Sciences, Hefei University of Technology, in conducting the SEM-EDS analysis of the specimens.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chang, Y., Zhou, D., Wang, Y.L. et al. Repulsive Interaction of Sulfide Layers on Compressor Impeller Blades Remanufactured Through Plasma Spray Welding. J. of Materi Eng and Perform 25, 5343–5351 (2016). https://doi.org/10.1007/s11665-016-2364-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2364-1