Abstract

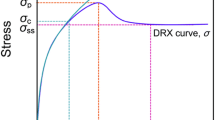

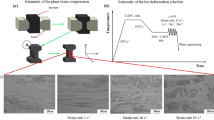

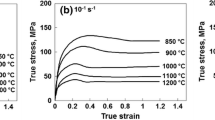

A constitutive model has been established based on dislocation theory, work hardening and dynamic recovery theory, and softening mechanisms of dynamic recrystallization. The stress-strain curves of a bainite steel have been measured with hot compression experiments at temperatures of 1173, 1273, 1373 and 1473 K with strain rates of 0.01, 0.1, 1 and 10 s−1 on a thermo-mechanical simulator (Gleeble-1500). The material constants involved in the constitutive model have been optimized by an inverse analysis of the stress-strain curves using the method of coordinate rotation, determining the strain-stress relationship or the constitutive equation, the kinetic models of dynamic recovery and dynamic recrystallization, and a few material constants of the investigated steel. Comparison of the calculated flow stress with the experimental data suggests that the relationship between the flow stress and the strain rate, temperature, strain of the steel during hot deformation can be described by the constitutive model, and that the underlying materials science can be captured from the material constants determined by the stress-strain curves.

Similar content being viewed by others

References

Z. Akbari, H. Mirzadeh, and J.-M. Cabrera, A Simple Constitutive Model for Predicting Flow Stress of Medium Carbon Microalloyed Steel During Hot Deformation, Mater. Des., 2015, 77, p 126–131

E.S. Puchi-Cabrera, J.D. Guerin, M. Dubar, M.H. Staia, J. Lesage, and D. Chicot, Constitutive Description of Fe-Mn23-C0.6 Steel Deformed Under Hot-Working Conditions, Int. J. Mech. Sci., 2015, 99, p 143–153

D. Feng, X.M. Zhang, S.D. Liu, and Y.L. Deng, Constitutive Equation and Hot Deformation Behavior of Homogenized Al-7.68Zn-2.12Mg-1.98Cu-0.12Zr Alloy During Compression at Elevated Temperature, Mater. Sci. Eng. A, 2014, 608, p 63–72

T. Yan, E. Yu, and Y. Zhao, Constitutive Modeling for Flow Stress of 55SiMnMo Bainite Steel at Hot Working Conditions, Mater. Des., 2013, 50, p 574–580

S.V. Mehtonen, L.P. Karjalainen, and D.A. Porter, Modeling of the High Temperature Flow Behavior of Stabilized 12-27 wt% Cr Ferritic Stainless Steels, Mater. Sci. Eng. A, 2014, 607, p 44–52

Y.G. Liu, M.Q. Li, and J. Luo, The Modelling of Dynamic Recrystallization in the Isothermal Compression of 300 M Steel, Mater. Sci. Eng. A, 2013, 574, p 1–8

B. Wu, M.Q. Li, and D.W. Ma, The Flow Behavior and Constitutive Equations in Isothermal Compression of 7050 Aluminum Alloy, Mater. Sci. Eng. A, 2012, 542, p 79–87

I. Mejia, G. Altamirano, A. Bedolla-Jacuinde, and J.M. Cabrera, Modeling of the Hot Flow Behavior of Advanced Ultra-High Strength Steels (A-UHSS) Microalloyed with Boron, Mater. Sci. Eng. A, 2014, 604, p 116–125

E.I. Poliakt and J.J. Jonas, A One-Parameter Approach to Determining the Critical Conditions for the Initiation of Dynamic Recrystallization, Acta Mater., 1996, 44, p 127–136

M. Wang, Y. Li, W. Wang, J. Zhou, and A. Chiba, Quantitative Analysis of Work Hardening and Dynamic Softening Behavior of low Carbon Alloy Steel Based on the Flow Stress, Mater. Des., 2013, 45, p 384–392

X.-M. Chen, Y.C. Lin, D.-X. Wen, J.-L. Zhang, and M. He, Dynamic Recrystallization Behavior of a Typical Nickel-Based Superalloy During Hot Deformation, Mater. Des., 2014, 57, p 568–577

M.A. Mostafaei and M. Kazeminezhad, A Novel Approach to Find the Kinetics of Dynamic Recovery Based on Hot Flow Curves, Mater. Sci. Eng. A, 2012, 544, p 88–91

W.F. Cui, S.X. Zhang, Y. Jiang, J. Dong, and C.M. Liu, Mechanical Properties and Hot-Rolled Micro-Structures of a Low Carbon Bainitic Steel with Cu-P Alloying, Mater. Sci. Eng. A, 2011, 528, p 6401–6406

H.K. Sung, D.H. Lee, S.Y. Shin, S. Lee, J.Y. Yoo, and Y. Hwang, Effect of Finish Cooling Temperature on Microstructure and Mechanical Properties of High-Strength Bainitic Steels Containing Cr, Mo, and B, Mater. Sci. Eng. A, 2015, 624, p 14–22

X. Kong, L. Lan, Z. Hu, B. Li, and T. Sui, Optimization of Mechanical Properties of High Strength Bainitic Steel Using Thermo-Mechanical Control and Accelerated Cooling Process, J. Mater. Process. Technol., 2015, 217, p 202–210

R. Sandstrom, On Recovery of Dislocations in Subgrains and Subgrain Coalescence, Acta Metall., 1977, 25, p 897–904

E.I. Galindo-Nava, J. Sietsma, and P.E.J. Rivera-Diaz-del-Castillo, Dislocation Annihilation in Plastic Deformation: II. Kocks-Mecking Analysis, Acta Mater., 2012, 60, p 2615–2624

L. Li, B. Ye, S. Liu, S. Hu, and B. Li, Inverse Analysis of the Stress-Strain Curve to Determine the Materials Models of Work Hardening and Dynamic Recovery, Mater. Sci. Eng. A, 2015, 636, p 243–248

E.I. Galindo-Nava and P.E.J. Rivera-Diaz-del-Castillo, Modelling Plastic Deformation in BCC metals: Dynamic Recovery and Cell Formation Effects, Mater. Sci. Eng. A, 2012, 558, p 641–648

D.-W. Suh, J.-Y. Cho, K.H. Oh, and H.-C. Lee, Evaluation of Dislocation Density from the Flow Curves of Hot Deformed Austenite, ISIJ Int., 2002, 42, p 564–569

U.F. Kocks and H. Mecking, Physics and Phenomenology of Strain Hardening: the FCC Case, Prog. Mater. Sci., 2003, 48, p 171–273

X.G. Fan, H. Yang, Z.C. Sun, and D.W. Zhang, Quantitative Analysis of Dynamic Recrystallization Behavior Using a Grain Boundary Evolution Based Kinetic Model, Mater. Sci. Eng. A, 2010, 527, p 5368–5377

C. Wu, H. Yang, and H.W. LI, Simulated and Experimental Investigation on Discontinuous Dynamic Recrystallization of a Near-αTA15 Titanium Alloy During Isothermal Hot Compression in βSingle-Phase Field, Trans. Nonferrous Met. Soc. China, 2014, 24, p 1819–1829

R. Liu, M. Salahshoor, S.N. Melkote, and T. Marusich, A Unified Internal State Variable Material Model for Inelastic Deformation and Microstructure Evolution in SS304, Mater. Sci. Eng. A, 2014, 594, p 352–363

X. Liang, J.R. McDermid, O. Bouaziz, X. Wang, J.D. Embury, and H.S. Zurob, Microstructural Evolution and Strain Hardening of Fe-24Mn and Fe-30Mn Alloys During Tensile Deformation, Acta Mater., 2009, 57, p 3978–3988

L. Delannay, P. Jacques, and T. Pardoen, Modelling of the Plastic Flow of Trip-Aided Multiphase Steel Based on an Incremental Mean-Field Approach, Int. J. Solids Struct., 2008, 45, p 1825–1843

J. Zhang, H. Di, X. Wang, Y. Cao, J. Zhang, and T. Ma, Constitutive Analysis of the Hot Deformation Behavior of Fe-23Mn-2Al-0.2C Twinning Induced Plasticity Steel in Consideration of Strain, Mater. Des., 2013, 44, p 354–364

L.P. Karjalainen, T.M. Maccagno, and J.J. Jonas, Softening and Flow Stress Behaviour During Hot Rolling Simulation of Nb Microalloyed Steels, ISIJ Int., 1995, 35, p 1523–1531

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, L., Ye, B., Liu, S. et al. A Unified Constitutive Equation of a Bainite Steel During Hot Deformation. J. of Materi Eng and Perform 25, 4581–4586 (2016). https://doi.org/10.1007/s11665-016-2302-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2302-2