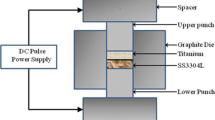

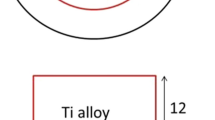

Diffusion bonding of high-strength titanium (Ti) to stainless steel (SS) (i.e., transition joint of lap configuration) is designed and assessed for the possible high-temperature, high-pressure applications for the nuclear power plant and chemical industries. The strength of annular joint is enhanced by providing grooves at the interface ensuring strength of the joint compatible to Ti. The optimized hot forming conditions are utilized to facilitate the flow of Ti to fill the grooves located at the interface on SS sleeve resulting in strong mechanical connection. The shrinkage stress developed due to differential contraction during cooling facilitates the diffusion bonding at the interfaces inside the grooves under relatively lower temperature. The present design concept results in the formation of low level of intermetallic compounds at the interface. The bond width containing the intermetallic compounds toward Ti side has been found to be less than that of the high-strength diffusion bonds as occasionally reported in the open published literatures.

Similar content being viewed by others

References

A.H.M.E. Rahman and M.N. Cavalli, Strength and Microstructure of Diffusion Bonded Titanium Using Silver and Copper Interlayers, Mater. Sci. Eng. A, 2010, 527, p 5189–5193

E. Atasoy and N. Kahraman, Diffusion Bonding of Commercially Pure Titanium to Low Carbon Steel Using a Silver Interlayer, Mater. Charact., 2008, 59, p 1481–1490

P. He, J. Zhang, R. Zhou, and X. Li, Diffusion Bonding Technology of a Titanium Alloy to a stainless Steel Web with an Ni Interlayer, Materials Characterization, Mater. Charact., 1999, 43, p 287–292

B. Aleman, I. Gutierrez, and J.J. Urcola, Interface Microstructures in Diffusion Bonding of Titanium Alloys to Stainless and Low Alloy Steels, Mater. Sci. Technol., 1993, 9, p 633–641

M. Ferrante and E.V. Pigoretti, Diffusion Bonding of Ti-6Al-4V to AISI 316L Stainless Steel: Mechanical Resistance and Interface Microstructure, J. Mater. Sci., 2002, 37, p 2825–2833

N.F. Kazakov, Diffusion Bonding of Materials, Mir Publication, Moscow, 1985

G.V.T. Ranzetta and J. Pearson, Microanalysis of Diffusion Bonds Between 18:8 Stainless Steel and Titanium, Met. Mater., 1969, 3, p 478–481

K. Bhanumurthy and G.B. Kale, Reactive Diffusion Between Titanium and Stainless Steel, J. Mater. Sci. Lett., 1993, 12, p 1879

S. Kundu, M. Ghosh, A. Laik, K. Bhanumurthy, G.B. Kale, and S. Chatterjee, Diffusion Bonding of Commercially Pure Titanium to 304 Stainless Steel Using Copper Interlayer, Mater. Sci. Eng. A, 2005, 407, p 154–160

S.C. Church and R.K. Wild, Diffusion Bonding of Steel to Ti-6Al-4V to Produce Hard Wearing Surface Layers, J. Vac. Sci. Technol. A, 1988, 16, p 536–538

M.K. Thota and R. Kapoor, High Temperature Deformation of α-Ti, Material Science and Engineering A, Mater. Sci. Eng. A, 2015, 624, p 213–219

A.B. Mukherjee, S.C. Swarnakar, and J.K. Chakravartty, Design, development and qualification of a titanium to stainless steel pipe joint with groove at the interface, Int. J. Manuf. Res. (under review)

A.B. Mukherjee, R. Kapoor, M.K. Thota, and J.K. Chakravartty, Numerical Modeling of Ti Deformation for the Development of a Titanium and Stainless Steel Transition Joint, J. Mater. Eng. Perform., 2016, 25, p 2679–2689

M. Allam and A. Bazergui, Axial Strength of Tube to Tubesheet Joints: Finite Element and Experimental Evaluations, Trans. ASME, 2002, 124, p 22–30

F.P.E. Dunne and I. Katramados, Large Deformation Compression–Torsion Behavior of a Titanium Alloy and its Modeling, Int. J. Mech. Sci., 1998, 40, p 901–912

Y. Zhu, W. Zeng, X. Ma, Q. Tai, Z. Li, and X. Li, Determination of the Friction Factor of Ti-6Al-4V Titanium Alloy in Hot Forging by Means of Ring–Compression Test Using FEM, Tribol. Int., 2001, 44, p 2074–2080

M. Brunig, Nonlinear Finite Element Analysis Based on a Large Strain Deformation Theory of Plasticity, Comput. Struct., 1998, 69, p 117–128

A.M. Kliauga, D. Travessa, and M. Ferrante, Al2O3/Ti Interlayer/AISI 304 Diffusion Bonded Joint Microstructural Characterization of the Two Interfaces, Mater. Charact., 2001, 46, p 65–74

T. Yamane and A. Miyakubi, Phase Formation in Ti-Fe Alloys, Proceedings of the 4th International Conference of Titanium, 1980, Kyoto, Japan, p 1309–1316

Acknowledgments

Technical assistance of Mr. P. Sinha and Dr. B. Paul of Materials Group, Bhabha Atomic Research Centre, is gratefully acknowledged. The authors would also like to acknowledge the assistance provided by Mr. J.K. Dhondkar for the experimental work and Mr. S.C. Swarnakar for the FEM analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mukherjee, A.B., Laik, A., Kain, V. et al. Shrinkage-Stress Assisted Diffusion Bonds Between Titanium and Stainless Steel: A Novel Technique. J. of Materi Eng and Perform 25, 4425–4436 (2016). https://doi.org/10.1007/s11665-016-2284-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2284-0