Abstract

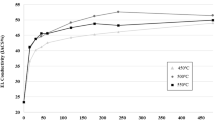

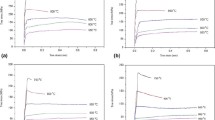

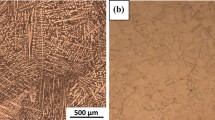

Microstructure evolution and hardness changes of an ultra-high strength Cu-Ni-Si alloy during thermo-mechanical processing have been investigated. For hot-compressive deformation specimens, dynamic recrystallization preferentially appeared on deformation bands. As deformation temperature increased from 750 to 900 °C, elongated grains with the Cubic texture {001} 〈100〉 were substituted by recrystallized grains with Copper texture {112} 〈111〉. For the samples having undergone cold rolling followed by annealing, static recrystallization preferentially occurred in the deformation bands, and then complete recrystallization occurred. Goss, Cubic, and Brass textures remained after annealing at 600 and 700 °C for 1 h; R texture {111} 〈211〉 and recrystallization texture {001} 〈100〉 were formed in samples annealed at 800 and 900 °C for 1 h, respectively. For samples processed under multi-directional forging at cryogenic temperature, the hardness was increased as a result of work hardening and grain refinement strengthening. These were attributed to the formation of equiaxed sub-grain structures and a high dislocation density.

Similar content being viewed by others

References

Q.Y. Dong, L.N. Shen, F. Cao, Y.L. Jia, K.J. Liao, and M.P. Wang, Effect of Thermomechanical Processing on the Microstructure and Properties of a Cu-Fe-P Alloy, J. Mater. Eng. Perform., 2015, 24(4), p 1531–1539

H.C. Chen, G. Bi, M.L.S. Nai, and J. Wei, Enhanced Welding Efficiency in Laser Welding of Highly Reflective Pure Copper, J. Mater. Process. Technol., 2015, 216, p 287–293

A.Y. Khereddine, F.H. Larbi, M. Kawasaki, T. Baudin, D. Bradai, and T.G. Langdon, An Examination of Microstructural Evolution in a Cu-Ni-Si Alloy Processed by HPT and ECAP, Mater. Sci. Eng. A, 2013, 576, p 149–155

I. Shakhova, Z. Yanushkevich, I. Fedorova, A. Belyakov, and R. Kaibyshev, Grain Refinement in a Cu-Cr-Zr Alloy During Multidirectional Forging, Mater. Sci. Eng. A, 2014, 606, p 380–389

H. Tsubakino, R. Nozato, and A. Yamamoto, Precipitation Sequence for Simultaneous Continuous and Discontinuous Modes in Cu-Be Binary Alloys, Mater. Sci. Technol., 1993, 9(4), p 288–294

B. Djurić, M. Jovanović, and D.J. Drobnjak, A Study of Precipitation in Cu-Be Alloys, Metallography, 1980, 13, p 235–247

W.S. Jeon, C.C. Shur, J.G. Kim, S.Z. Han, and Y.S. Kim, Effect of Cr on the Corrosion Resistance of Cu-6Ni-4Sn Alloys, J. Alloys Compd., 2008, 455, p 358–363

F.L. Wang, Y.P. Li, K. Wakoh, Y. Koizumi, and A. Chiba, Cu-Ti-C Alloy with High Strength and High Electrical Conductivity Prepared by Two-Step Ball-Milling Processes, Mater. Des., 2014, 61, p 70–74

L.N. Shen, Z. Li, Z.M. Zhang, Q.Y. Dong, Z. Xiao, Q. Lei, and W.T. Qiu, Effects of Silicon and Thermo-mechanical Process on Microstructure and Properties of Cu-10Ni-3Al-0.8Si Alloy, Mater. Des., 2014, 62, p 265–270

W.H. Sun, H.H. Xu, S.H. Liu, Y. Du, Z.H. Yuan, and B.Y. Huang, Phase Equilibria of the Cu-Ni-Si System at 700 °C, J. Alloys Compd., 2011, 509(41), p 9776–9781

S.A. Lockyer and F.W. Noble, Precipitate Structure in a Cu-Ni-Si Alloy, J. Mater. Sci., 1994, 29(1), p 218–226

Q. Lei, Z. Li, J. Wang, J.M. Xie, X. Chen, S. Li, Y. Gao, and L. Li, Hot Working Behavior of a Super High Strength Cu-Ni-Si Alloy, Mater. Des., 2013, 51, p 1104–1109

X.J. Liu, S.L. Xiang, S.Y. Yang, R.P. Shi, and C.P. Wang, Experimental Investigation of Phase Equilibria in the Cu-Ni-Si Ternary System, J. Alloys Compd., 2013, 578, p 439–447

H. Azzeddine, B. Mehdi, L. Hennet, D. Thiaudière, B. Alili, M. Kawasaki, D. Bradai, and T.G. Langdon, An In Situ Synchrotron X-Ray Diffraction Study of Precipitation Kinetics in a Severely Deformed Cu-Ni-Si Alloy, Mater. Sci. Eng. A, 2014, 597, p 288–294

C. Watanabe and R. Monzen, Coarsening of δ-Ni2Si Precipitates in a Cu-Ni-Si Alloy, J. Mater. Sci., 2011, 46(12), p 4327–4335

Z.Y. Pan, M.P. Wang, Z. Li, C.P. Deng, S.H. Li, and Y.L. Jia, Progress of Study of Super-High Strength Cu-Ni-Si Alloy, Heat Treat. Met., 2007, 7, p 55–59

Z. Li, Z.Y. Pan, Y.Y. Zhao, Z. Xiao, and M.P. Wang, Microstructure and Properties of High Conductivity, Super High Strength Cu-8.0Ni-1.8Si-0.6Sn-0.15Mg Alloy, J. Mater. Res., 2009, 24, p 2123–2129

Q. Lei, Z. Li, M.P. Wang, L. Zhang, Z. Xiao, and Y.L. Jia, The Evolution of Microstructure in Cu-8.0 Ni-1.8 Si-0.15 Mg Alloy During Aging, Mater. Sci. Eng. A, 2010, 527, p 6728–6733

J.Y. Cheng, B.B. Tang, F.X. Yu, and B. Shen, Evaluation of Nanoscaled Precipitates in a Cu-Ni-Si-Cr Alloy During Aging, J. Alloys Compd., 2014, 614, p 189–195

A.Y. Khereddine, F.H. Larbi, H. Azzeddine, T. Baudin, F. Brisset, A.L. Helbert, M.H. Mathon, M. Kawasaki, D. Bradai, and T.G. Langdon, Microstructures and Textures of a Cu-Ni-Si Alloy Processed by High-Pressure Torsion, J. Alloys Compd., 2013, 574, p 361–367

Q. Lei, Z. Li, C. Dai, J. Wang, X. Chen, J.M. Xie, W.W. Yang, and D.L. Chen, Effect of Aluminum on Microstructure and Property of Cu-Ni-Si Alloys, Mater. Sci. Eng. A, 2013, 572, p 65–74

Q. Lei, Z. Li, T. Xiao, Y. Pang, Z.Q. Xiang, W.T. Qiu, and Z. Xiao, A New Ultrahigh Strength Cu-Ni-Si Alloy, Intermetallics, 2013, 42, p 77–84

T. Konkova, S. Mironov, A. Korznikov, and S.L. Semiatin, Microstructural Response of Pure Copper to Cryogenic Rolling, Acta Mater., 2010, 58, p 5262–5273

Y.P. Lü, D.A. Molodov, and G. Gottstein, Recrystallization Kinetics and Microstructure Evolution During Annealing of a Cold-Rolled Fe-Mn-C Alloy, Acta Mater., 2011, 59, p 3229–3243

J.J. Sidor and L.A.I. Kestens, Analytical Description of Rolling Textures in Face-Centred- Cubic Metals, Scr. Mater., 2013, 68(5), p 273–276

N. Jia, Z.H. Nie, Y. Ren, R.L. Peng, Y.D. Wang, and X. Zhao, Formation of Deformation Textures in Face-Centered-Cubic Materials Studied by In-Situ High-Energy X-Ray Diffraction and Self-Consistent Model, Metall. Mater. Trans. A, 2010, 41(5), p 1246–1254

Y. Huang and P.B. Prangnell, The Effect of Cryogenic Temperature and Change in Deformation Mode on the Limiting Grain Size in a Severely Deformed Dilute Aluminium Alloy, Acta Mater., 2008, 56(7), p 1619–1632

R.E. Smallman and D. Green, The Dependence of Rolling Texture on Stacking Fault Energy, Acta Metall., 1964, 12(2), p 145–154

S.H. Kim, S.Z. Han, C.J. Kim, I.Y. Hwang, and F.X. Yin, Evolution of Rolling Textures of Cold Rolled Copper Foils, Mater. Trans., 2009, 50(3), p 537–543

I.A. Yakubtsov, A. Ariapour, and D.D. Perovic, Effect of Nitrogen on Stacking Fault Energy of F.C.C. Iron-Based Alloys, Acta Mater., 1999, 47(4), p 1271–1279

Q. Lei, Z. Li, A.Y. Zhu, W.T. Qiu, and S.Q. Liang, The Transformation Behavior of Cu-8.0Ni-1.8Si-0.6Sn-0.15Mg Alloy During Isothermal Heat Treatment, Mater. Charact., 2011, 62, p 904–911

Q. Lei, Z. Li, J. Wang, S. Li, L. Zhang, and Q.Y. Dong, High-Temperature Deformation Behavior of Cu-6.0Ni-1.0Si-0.5Al-0.15 Mg-0.1Cr Alloy, J. Mater. Sci., 2012, 47, p 6034–6042

F.H. Larbi, H. Azzeddine, T. Baudin, M.H. Mathon, F. Brisset, A.L. Helbert, M. Kawasaki, D. Bradai, and T.G. Langdon, Microstructure and Texture Evolution in a Cu-Ni-Si alloy Processed by Equal-Channel Angular Pressing, J. Alloys Compd., 2015, 638(25), p 88–94

H. Matsunaga, Z. Horita, K. Imamura, T. Kiss, and X. Sauvage, Aging Behavior of Cu-Ni-Si Alloy Processed by High-Pressure Torsion, Mater. Sci. Form., 2011, 667–669, p 307–312

I. Altenberger, H.A. Kuhn, M. Gholami, M. Mhaede, and L. Wangner, Ultrafine-Grained Precipitation Hardened Copper Alloy by Swaging or Accumulative Roll Bonding, Metals, 2015, 5, p 763–766

Acknowledgments

The authors are pleased to acknowledge the financial supply supported by the National Natural Science Foundation of China (51271203), the PPP Project between the CSC (China Scholarship Council) and the DAAD (German Academic Exchange Service), and the Nonferrous Metals Science Foundation of HNG-CSU (YSZN2013CL06).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lei, Q., Li, Z., Hu, W.P. et al. Microstructure Evolution and Hardness of an Ultra-High Strength Cu-Ni-Si Alloy During Thermo-mechanical Processing. J. of Materi Eng and Perform 25, 2615–2625 (2016). https://doi.org/10.1007/s11665-016-2147-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2147-8