Abstract

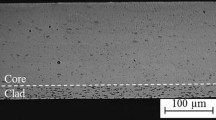

Successful brazing using Cu-based nanostructured brazing fillers at temperatures much below the bulk melting temperature of Cu was recently demonstrated (Lehmert et al. in, Mater Trans 56:1015–1018, 2015). The Cu-based nano-fillers are composed of alternating nanolayers of Cu and a permeable, non-wetted AlN barrier. In this study, a thermodynamic model is derived to estimate the melting point depression (MPD) in such Cu/AlN nano-multilayers (NMLs) as function of the Cu nanolayer thickness. Depending on the melting route, the model predicts a MPD range of 238-609 K for Cu10nm/AlN10nm NMLs, which suggests a heterogeneous pre-melting temperature range of 750-1147 K (476-874 °C), which is consistent with experimental observations. As suggested by basic kinetic considerations, the observed Cu outflow to the NML surface at the temperatures of 723-1023 K (450-750 °C) can also be partially rationalized by fast solid-state diffusion of Cu along internal interfaces, especially for the higher temperatures.

Similar content being viewed by others

References

B. Lehmert, J. Janczak-Rusch, G. Pigozzi, P. Zuraw, F. La Mattina, L. Wojarski, W. Tillmann, and L.P.H. Jeurgens, Copper-Based Nanostructured Coatings for Low-Temperature Brazing Applications, Mater. Trans., 2015, 56(7), p 1015–1018

G. Kaptay, J. Janczak-Rusch, G. Pigozzi, and L.P.H. Jeurgens, Theoretical Analysis of Melting Point Depression of Pure Metals in Different Initial Configurations, J. Mater. Eng. Perform., 2014, 23, p 1600–1607

Q.S. Mei and K. Lu, Melting and Superheating of Crystalline Solids: From Bulk to Nanocrystals, Progr. Mater. Sci., 2007, 52, p 1175–1262

G. Guenther and O. Guillon, Models of Size-Dependent Nanoparticle Melting Tested on Gold, J. Mater. Sci., 2014, 49, p 7915–7932

P. Pawlow, Über die Abhängigkeit des Schmelzpunktes von der Oberflächenergie eines festen Körpers, Z Phys. Chemie, 1908, 55, p 545–548

M. Takagi, Electron-Diffraction Study of Liquid-Solid Transition of Thin Solid Films, J. Phys. Soc. Japan, 1954, 9(3), p 359–363

J. Janczak-Rusch, G. Kaptay, and L.P.H. Jeurgens, Interfacial Design for Joining Technologies—An Historical Perspective, J. Mater. Eng. Perform., 2014, 23, p 1608–1613

Z. Wang, L.P.H. Jeurgens, and W. Sigle, Eric J. Mittemeijer, Observation and Origin of Extraordinary Atomic Mobility at Metal-Semiconductor Interfaces at Low Temperatures, Phys. Rev. Lett., 2015, 115, p 016102

R. Longtin, E. Hack, J. Neuenschwander, and J. Janczak-Rusch, Benign Joining of Ultrafine Grained Aerospace Aluminum Alloys Using Nanotechnology, Adv. Mater., 2011, 20, p 1–5

T.T. Bao, Y. Kim, J. Lee, and J.G. Lee, Preparation and Thermal Analysis of Sn-Ag Nano Solders, Mater. Trans., 2010, 51, p 2145–2149

C. Zou, Y. Gao, B. Yang, and Q. Zhai, Synthesis and DSC Study on Sn3.5Ag Alloy Nanoparticles Used for Lower Melting Temperature Solder, J. Mater. Sci.: Mater. Electron., 2010, 21, p 868–874

J.F. Pocza, A. Barna, and P.B. Barna, Formation Processes of Vacuum-Deposited Indium Films and Thermodynamical Properties of Submicroscopic Particles Observed by In-Situ Electron Microscopy, J. Vacuum Sci. Techn., 1969, 6(4), p 472–475

C.J. Coombes, The Melting of Small Particles of Lead and Indium, J. Phys. F, 1972, 2, p 441–449

J. Janczak-Rusch, G. Pigozzi, B. Lehmert, M. Parlinska, V. Bissig, W. Tillmann, L. Wojarski, F. Hoffmann, Proceedings of the of IBSC 2012—5th International Brazing and Soldering Conference, 2012, p 163

J. Janczak-Rusch, M. Chiodi, C. Cancellieri, F. Moszner, R. Hauert, G. Pigozzi, and L.P.H. Jeurgens, Structural Evolution of Ag–Cu Nano-Alloys Confined Between AlN Nano-Layers upon Fast Heating, Phys. Chem. Chem. Phys., 2015, 17, p 28228

G. Pigozzi, A. Antusek, J. Janczak-Rusch, M. Parlinska-Wojtan, D. Passerone, C.A. Pignedoli, V. Bissig, J. Patscheider, and L.P.H. Jeurgens, Phase Constitution and Interface Structure of Nano-Sized Ag-Cu/AlN Multilayers: Experimental and ab Initio Modeling, Appl. Phys. Lett., 2012, 101, p 181602

G. Garzel, J. Janczak-Rusch, and L. Zabdyr, Reassessment of the Ag-Cu Phase Diagram for Nanosystems Including Particle Size and Shape Effect, Calphad, 2012, 36, p 52–56

J. Janczak-Rusch, M. Chiodi, F. Moszner, C. Cancellieri, R. Hauert, L.P.H. Jeurgens, Development of nanostructured silver-based brazing fillers in a multilayer configuration for low-temperature joining, 68th Annual Assembly and International Conference, IIW 2015, SC-MICRO, Microjoining and Nanojoining Workshop, 28 June–3 July 2015, Helsinki, Finland, 2015

M. Chiodi, C. Cancellieri, F. Moszner, M. Andrzejczuk, J. Janczak-Rusch, L.P.H. Jeurgens, Massive Ag Migration Through Metal/Ceramic Nano-Multilayers: Interplay Between Temperature, Stress-Relaxation and Oxygen-Enhanced Mass Transport, J. Mater. Chem. C, 2016. doi:10.1039/C6TC01098A

J. Lipecka, J. Janczak-Rusch, M. Lewandowska, M. Andrzejczuk, G. Richter, L.P.H. Jeurgens, Phase Stability and Melting Point Depression of Nano-Confined Al-Si10at.% Alloys in AlSi/AlN Nano-Multilayered Brazing Fillers, 2016 (in preparation)

A.N. Belov, S.V. Bulyarsky, D.G. Gromov, L.M. Pavlova, and O.V. Pyatilova, Study of Silver Cluster Formation From Thin Films on Inert Surface, Calphad, 2014, 44, p 138–141

I. Barin, Thermomechanical Properties of Pure Substances, VCh, 1993, in 2 parts

A.T. Dinsdale, SGTE Data for Pure Elements, CALPHAD, 1991, 15, p 317–425

Ph Buffat and J.-P. Borel, Size Effect on the Melting Temperature of Gold Particles, Phys. Rev. A, 1976, 13, p 2287–2296

J.-G. Lee, J. Lee, T. Tanaka, and H. Mori, In Situ Atomic-Scale Observation of Melting Point Suppression in Nanometer-Sized Gold Particles, Nanotechnology, 2009, 20, p 475706

P.R. Couchman and W.A. Jesser, Thermodynamic Theory of Size Dependence of Melting Temperature in Metals, Nature, 1977, 269, p 481–483

F. Spaepen and D. Turnbull, Negative Pressures and Melting Point Depression in Oxide-Coated Liquid Metal Droplets, Scr. Metall., 1979, 13, p 149–151

G.L. Allen, W.W. Gile, and W.A. Jesser, The Melting Temperature of Microcrystals Embedded in a Matrix, Acta Metall., 1980, 28, p 1695–1701

R. Kofman, P. Cheyssac, A. Aouaj, Y. Lereah, G. Deuscher, T. Ben-David, J.M. Penisson, and A. Bourret, Surface Melting Enhanced by Curvature Effects, Surf. Sci., 1994, 303, p 231–246

K. Chattopadhyay and R. Goswami, Melting and Superheating of Metals and Alloys, Progr. Mater. Sci., 1997, 42, p 287–300

M. Wautelet, On the Shape Dependence of the Melting Temperature of Small Particles, Phys. Lett. A, 1998, 246, p 341–342

Z. Zhang, J.C. Li, and Q. Jiang, Modelling for Size-Dependent and Dimension-Dependent Melting of Nanocrystals, J. Phys. D, 2000, 33, p 2653–2656

Q. Jiang, Z. Zhang, and J.C. Li, Melting Thermodynamics of Nanocrystals Embedded in a Matrix, Acta Mater., 2000, 48, p 4791–4795

T. Tanaka and S. Hara, Thermodynamic Evaluation of Binary Phase Diagrams of Small Particle Systems, Z. Metallkd., 2001, 92, p 467–472

M. Hillert and J. Argen, Effect of Surface Free Energy and Surface Stress on Phase Equilibria, Acta Mater., 2002, 50, p 2429–2441

U. Tartaglino and E. Tosatti, Strain Effects at Solid Surfaces Near the Melting Point, Surf. Sci., 2003, 532–535, p 623–627

Q. Jiang, L.H. Liang, and J.C. Li, Thermodynamic Superheating of Low-Dimensional Metals Embedded in Matrix, Vacuum, 2003, 72, p 249–255

Z. Shi, P. Wynblatt, and S.G. Srinivasan, Melting Behavior of Nanosized Lead Particles Embedded in an Aluminium Matrix, Acta Mater., 2004, 52, p 2305–2316

V.M. Samsonov and O.A. Malkov, Thermodynamic Model of Crystallization and Melting of Small Particles, Central Eur. J. Phys., 2004, 2(1), p 90–103

Q.S. Mei, S.C. Wang, H.T. Cong, Z.H. Jin, and K. Lu, Determination of Pressure Effect on the Melting Point Elevation of Al Nanoparticles Encapsulated in Al2O3 Without Epitaxial Interface, Phys. Rev. B, 2004, 70, p 125421

J. Chang and E. Johnson, Surface and Bulk Melting of Small Metal Clusters, Philos. Mag., 2005, 85(30), p 3617–3627

J. Slutsker, K. Thornton, A.L. Roytburd, J.A. Warren, and G.B. McFadden, Phase Field Modeling of Solidification Under Stress, Phys. Rev. B, 2006, 74(1), p 014103

J.J. Hoyt, Effect of Stress on Melting and Freezing in Nanopores, Phys. Rev. Lett., 2006, 96(4), p 045702

G. Guisbiers and M. Wautelet, Size, Shape and Stress Effects on the Melting Temperature of Nano-Polyhedral Grains on a Substrate, Nanotechnology, 2006, 17, p 2008–2011

J. Sun and S.L. Simon, The Melting Behavior of Aluminum Nanoparticles, Thermochim. Acta, 2007, 463, p 32–40

G. Guisbiers, O. Van Overschelde, and M. Wautelet, Nanoparticulate Origin of Intrinsic Residual Stress in Thin Films, Acta Mater., 2007, 55, p 3541–3546

O.A. Yeshchenko, I.M. Dmitruk, A.A. Alexeenko, and A.M. Dmytruk, Size-Dependent Melting of Spherical Copper Nanoparticles Embedded in a Silica Matrix, Phys Rev B, 2007, 75(8), p 085434

P. Letellier, A. Mayaffre, and M. Turmine, Melting Point Depression of Nanosolids: Nonextensive Thermodynamics Approach, Phys. Rev. B, 2007, 76, p 045428

J. Lee, T. Tanaka, J. Lee, and H. Mori, Effect of Substrates on the Melting Temperature of Gold Nanoparticles, Calphad, 2007, 31, p 105–111

K.K. Nanda, Size-Dependent Melting of Nanoparticles: Hundred Years of Thermodynamic Model, Pramana J. Phys., 2009, 172, p 617–628

V.I. Levitas, M. Pantoya, G. Chauhan, and I.J. Rivero, Effect of the Alumina Shell on the Melting Temperature Depression for Aluminum Nanoparticles, Phys. Chem. C., 2009, 113(32), p 14088–14096

G. Kaptay, The Extension of the Phase Rule to Nano-Systems and on the Quaternary Point in One-Component Nano Phase Diagrams, J. Nanosci. Nanotechnol., 2010, 10, p 8164–8170

W. Luo, L. Deng, K. Su, K. Li, G. Liao, and S. Xiao, Gibbs Free Energy Approach to Calculate the Thermodynamic Properties of Copper Nanocrystals, Phys. B, 2011, 406, p 859–863

V.I. Levitas and K. Samani, Size and Mechanics Effects in Surface-Induced Melting of Nanoparticles, Nature Comm., 2011, 2, p 284

V.I. Levitas and K. Samani, Coherent Solid/Liquid Interface With Stress Relaxation in a Phase-Field Approach to the Melting/Solidification Transition, Phys. Rev. B, 2011, 84(14), p 140103

G. Kaptay, The Gibbs Equation Versus the Kelvin and the Gibbs-Thomson Equations to Describe Nucleation and Equilibrium of Nano-Materials, J. Nanosci. Nanotechnol., 2012, 12(3), p 2625–2633

A.I. Rusanov, The Development of the Fundamental Concepts of Surface Thermodynamics, Coll. J., 2012, 74(2), p 136–153

G. Kaptay, Nano-Calphad: Extension of the Calphad Method to Systems With Nano-Phases and Complexions, J. Mater. Sci., 2012, 47, p 8320–8335

V.I. Levitas, Z. Ren, Y. Zeng, Z. Zhang, and G. Han, Effect of the Alumina Shell on the Melting Temperature Depression for Aluminum Nanoparticles, Phys. Rev. B, 2012, 85(22), p 220104

J. Leitner and M. Kamrádek, Termodynamicky Popis Nanosystemu, Chem. Listy, 2013, 107, p 606–613

A. Firmansyah, K. Sullivan, K.S. Lee, Y.H. Kim, R. Zahaf, M.R. Zachariah, and D.J. Lee, Microstructural Behavior of the Alumina Shell and Aluminum Core Before and After Melting of Aluminum Nanoparticles, Phys. Chem. C, 2013, 116(1), p 404–411

J. Lee and K.J. Sim, General Equations of Calphad-Type Thermodynamic Description for Metallic Nanoparticle Systems, Calphad, 2014, 44, p 129–132

A. Junkaew, B. Ham, X. Zhang, and R. Arróyave, Tailoring the Formation of Metastable Mg Through Interfacial Engineering: A Phase Stability Analysis, Calphad, 2014, 45, p 45–150

I. Atanasov, R. Ferrando, and R.L. Johnston, Structure and Solid Solution Properties of Cu–Ag Nanoalloys, J. Phys.: Condens. Matter, 2014, 26, p 275301–275309

J. Sopousek, O. Zobac, J. Bursık, P. Roupcova, V. Vykoukal, P. Broz, J. Pinkas, and J. Vrestal, Heat-Induced Spinodal Decomposition of Ag–Cu Nanoparticles, Phys. Chem. Chem. Phys., 2015, doi:10.1039/c5cp00198f

S. Bajaj, M.G. Haverty, R. Arróyave, W.A. Goddard, III, and S. Shankar, Phase Stability in Nanoscale Material Systems: Extension From Bulk Phase Diagrams, Nanoscale, 2015, doi:10.1039/c5nr01535a

L. Wojtczak, The Melting point of Thin Films, Phys. Stat. Sol., 1967, 22, p K163–K166

C.L. Chen, J.-G. Lee, K. Arakawa, and H. Mori, In Situ Observations of Crystalline-to-Liquid and Crystalline-to-Gas Transitions of Substrate-Supported Ag Nanoparticles, Appl. Phys. Lett., 2010, 96, p 253104

L.P.H. Jeurgens, Z. Wang, and E.J. Mittemeijer, Thermodynamics of Reactions and Phase Transformations at Interfaces and Surfaces, Int. J. Mater. Res., 2009, 100, p 1281–1307

D.G. Gromov and S.A. Gavrilov, Manifestation of the Heterogeneous Mechanism Upon Melting of Low-Dimensional Systems, Phys. Solid State, 2009, 51(10), p 2135–2144

H.W. Sheng, G. Ren, L.M. Peng, Z.Q. Hu, and K. Lu, Epitaxial Dependence of the Melting Behavior of In Nanoparticles Embedded in Al matrices, J Mater Res, 1997, 12(1), p 119–123

H.W. Sheng, K. Lu, and E. Ma, Acta Mater., 1998, 46, p 5195

L.P.H. Jeurgens, W.G. Sloof, F.D. Tichelaar, and E.J. Mittemeijer, Thermodynamic Stability of Amorphous Oxide Films on Metals: Application to Aluminium-Oxide Films on Aluminium Substrates, Physical Review B, 2000, 62, p 4707–4719

J. Emsley, The Elements, Clarendon Press, Oxford, 1989

Y.S. Touloukian, R.K. Kirby, R.E. Taylor, and T.Y.R. Lee, Thermal Expansion, IFI/Plenum, New York, 1977

G. Kaptay, Approximated Equations for Molar Volumes of Pure Solid Fcc Metals and Their Liquids From Zero Kelvin to Above Their Melting Points at Standard Pressure, J. Mater. Sci., 2015, 50, p 678–687

T. Iida and R.I.L. Guthrie, The Physical Properties of Liquid Metals, Clarendon Press, Oxford, 1993

G. Kaptay, A Unified Model for the Cohesive Enthalpy, Critical Temperature, Surface Tension and Volume Thermal Expansion Coefficient of Liquid Metals of Bcc, Fcc and Hcp Crystals, Mater. Sci. Eng. A, 2008, 495, p 19–26

N. Eustathopoulos, M.G. Nicholas, and B. Drevet, Wettability at High Temperatures, Pergamon, Amsterdam, 1999

G. Kaptay, E. Báder, and L. Bolyán, Interfacial Forces and Energies Relevant to Production of Metal Matrix Composites, Mater. Sci. Forum, 2000, 329–330, p 151–156

G. Kaptay, Modeling Interfacial Energies in Metallic Systems, Mater. Sci. Forum, 2005, 473–474, p 1–10

K. Maier, Self-diffusion in Copper at “Low” Temperatures, Phys. Status solidi (a), 1977, 44, p 567

E. Budke, T. Surholt, S.I. Prokofjev, and L.S. Shvindlerman, Chr. Herzig, Tracer Diffusion of Au and Cu in a Series of Near & #xF053; = 5 (310)(Ref 001) Symmetrical Cu Tilt Grain, Acta Mater., 1999, 47, p 385

D.R. Poirier and G.H. Geiger, Transport Phenomena in Materials Processing, TMS, Warrendale, 1994, p 658

Acknowledgment

The authors acknowledge Benjamin Lehmert (Dortmund University of Technology, Germany) for sputter deposition of the Cu/AlN NMLs in Fig. 1, as well as Fabio La Mattina and Ivan Shorubalko (Empa) for performing the cross-sectional He-FIB analysis in Fig. 1. The financial support of EU FP7-PEOPLE-2013-IRSES Project EXMONAN—Experimental investigation and modelling of nanoscale solid state reactions with high technological impact is greatly acknowledged. GK thanks the TÁMOP-4.2.1.B-10/2/KONV-2010-0001 and the TÁMOP-4.2.2.A-11/1/KONV-2012-0019 project in the framework of the New Széchenyi Plan, supported by the European Union, and co-financed by the European Social Fund.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited submission to JMEP selected from presentations at the Symposium “Interface Design and Modeling,” belonging to the Topic “Joining and Interfaces” at the European Congress and Exhibition on Advanced Materials and Processes (EUROMAT 2015), held September 20-24, 2015, in Warsaw, Poland, and has been expanded from the original presentation.

Appendix 1: Physico-Chemical Properties for the Cu/AlN NML System

Appendix 1: Physico-Chemical Properties for the Cu/AlN NML System

The standard melting point and molar melting entropy of Cu are \(T_{m}^{\text{o}}\) = 1357.77 K (Ref 23) and \(\Delta_{m} S_{\text{mol}}^{\text{o}}\) = 9.51 J/mol K (Ref 23), respectively. The standard Gibbs energy change accompanying melting of pure Cu below its standard melting point (J/mol) is obtained from (Ref 23):

The T-dependence of the molar volume of solid Cu (cm3/mol) is obtained from (Ref 74-76):

The standard surface tension \(\sigma_{l/g}^{\text{o}}\) (J/m2) and surface energy \(\sigma_{s/g}^{\text{o}}\) (J/m2) of Cu equal (Ref 77, 78):

The liquid/barrier interfacial energy is written from the Young-Dupré equation as (Ref 79):

where \(\sigma_{b/g}^{\text{o}}\) (J/m2) is the surface energy of the barrier (AlN in our case), \(W_{l/b}^{\text{o}}\) (J/m2) is the adhesion energy between the liquid metal and the barrier, which can be expressed as

At the Cu melting point, \(\sigma_{l/b}^{\text{o}}\) = 1.30 J/m2 (see Eq 10). The surface energy of AlN is about (Ref 80) (J/m2):

The contact angle of liquid Cu on AlN, being a covalent and non-reactive ceramic, is about 150° (Ref 79). Thus, as follows from Eq 13, the adhesion energy at the melting point of Cu is about \(W_{l/b}^{\text{o}}\) = 0.17 J/m2, which to a first approximation is taken T-independent. Thus, the T-dependence of \(\sigma_{l/b}^{\text{o}}\) (J/m2) is obtained by combining Eq 10, 12, 14:

The interface between solid Cu and AlN is incoherent (Ref 15, 16). Neglecting lattice mismatch strain (Ref 69), the adhesion energy is similar to that of the liquid Cu, i.e., \(W_{s/b}^{\text{o}}\) = 0.17 J/m2. Then, the solid metal/barrier interfacial energy approximately equals (see Eq 11, 12, 14):

To a first approximation, the grain boundary energy of the barrier layer can be taken as 1/3 of its surface energy, \(\sigma_{b/g}^{\text{o}}\) in Eq 14 (Ref 81), i.e.,

Rights and permissions

About this article

Cite this article

Kaptay, G., Janczak-Rusch, J. & Jeurgens, L.P.H. Melting Point Depression and Fast Diffusion in Nanostructured Brazing Fillers Confined Between Barrier Nanolayers. J. of Materi Eng and Perform 25, 3275–3284 (2016). https://doi.org/10.1007/s11665-016-2123-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2123-3