Abstract

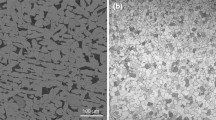

The corrosion behavior of a thermal-sprayed stainless steel (SS)-coated Q235 steel has been investigated in simulated soil solutions using electrochemical measurements, x-ray photoelectron spectroscopy analysis, and scanning electron microscope. The as-received Q235 steel and galvanized steel for grounding grids were also examined for the purpose of comparison. The effects of pH value of testing solutions have been examined. The thermal-sprayed SS-coated steel showed the best corrosion resistance among the three kinds of materials. With increasing pH value, the corrosion resistance of SS-coated Q235 steel increased. In weak alkaline solutions, the SS-coated Q235 steel showed the largest polarization resistance (3.2 × 105 Ω cm2), the lowest anodic current density (1.4 × 10−2 μA/cm2), and the largest film resistance (4.5 × 106 Ω cm2), suggesting that the coated steel has the best corrosion resistance in weak alkaline environment. Related corrosion mechanisms are also discussed.

Similar content being viewed by others

References

Y.F. Yu, Y.Z. Zhan, Z.W. Lin, and Z. Yuan, Research on 220 kV Substation Ground Grid Corrosion Status in Hubei Power Grid, Hubei Electr. Power, 2007, 31, p 5–7

A.J. Yan, X. Chen, and L.J. Feng, Soil Corrosion Performance of Several Grounding Net Materials, Corros. Sci. Prot. Technol., 2010, 22, p 197–199

F.J. Yan and X.G. Li, Corrosion and Protection of Grounding Net in Electric Power System, Shandong Electr. Power Technol., 2007, 34, p 15–18

ANSI/IEEE Standard No. 80-2000, IEEE Guide for Safety in AC Substation Grounding, The Institute of Electrical and Electronics Engineers, New York, 2000

M.C. Zheng, Z.N. Chen, and J.H. Li, Research on Corrosion Characteristics of Corrosion Rule and Anti-corrosion Technology of Grounding Device for Large Substations, East China Electr. Power, 2009, 37, p 1463–1467

M. Loboda and R. Marciniak, Field Corrosion Test in Poland of Copper Coated Steel Earthing Rods for LPS, 29th International Conference on Lightning Protection, Sweden, 2008, p 5–9

Y.H. Wu, T.M. Liu, C. Sun, J. Xu, and C.K. Yu, Corrosion Behaviors of Copper in Acidic Soil Acidified with Simulated Acid Rain, J. Sichuan Univ., 2010, 42, p 119–125

J.S. Chen, Copper Grounding Conductor Cause Harm. http://www.500kv.net/copper.html

Anonymous, Thermal Spray Coatings Protect Steel Structures from Corrosion, Adv. Mater. Process., 2007, 165, p 114–115

S. Papavinsasam, M. Attard, B. Arseneult, and R.W. Revie, State-of-the-Art of Thermal Spray Coatings for Corrosion Protection, Corros. Rev., 2008, 26, p 105–146

Z. Zeng, N. Sakoda, and T. Tajiri, Corrosion Behavior of Wire-Arc-Sprayed Stainless Steel Coating on Mild Steel, J. Therm. Spray Technol., 2006, 15, p 431–437

H.T. Cai, T. Jiang, and Y. Zhou, Research Status and Development of the Thermal Spray Technology, Equip. Manuf. Technol., 2014, 42, p 28–32

X.Q. Wu, J. Xu, W. Ke, S. Xu, B. Feng, and B.T. Hu, Effects of pH Value on Corrosion Behavior of Thermal-Sprayed Al-Si Coated Q235 Steel in Simulated Soil Solutions, J. Mater. Eng. Perform., 2014, 23, p 2265–2273

C.N. Cao, Principles of Electrochemistry of Corrosion, Chemical Industry Press, Beijing, 2008

M. Keddam, O.R. Mattos, and H. Takenouti, Mechanism of Anodic Dissolution of Iron-chromium Alloys Investigated by Electrode Impedances—I. Experimental Results and Reaction Model, Electrochem. Acta, 1986, 31, p 1147–1158

R.F.A. Jargenlius-Pettersson and B.G. Pound, Examination of the Role of Molybdenum in Passivation of Stainless Steels Using AC Impedance Spectroscopy, J. Electrochem. Soc., 1998, 145, p 1462–1469

H. Sun, X.Q. Wu, and E.H. Han, Effects of Temperature on the Properties of the Oxide Film Formed on 304 SS in High Temperature Lithium Borate Buffer Solution, Corros. Sci., 2009, 51, p 2840–2847

J. Xu, X.Q. Wu, and E.H. Han, The Evolution of Electrochemical Behaviour and Oxide Film Properties of 304 Stainless Steel in High Temperature Aqueous Environment, Electrochim. Acta, 2012, 71, p 219–226

H. Sun, “Electrochemical Corrosion Behaviors and Oxide Film Properties of Stainless Steels and Nickel-Based Alloys in High Temperature and High Pressure Aqueous Environments”, Ph.D. Thesis, Chinese Academy of Sciences, 2010

H. Sun, X.Q. Wu, and E.H. Han, Effects of Temperature on the Protective Property, Structure and Composition of the Oxide Film on Alloy 625, Corros. Sci., 2009, 51, p 2565–2572

A. Machet, A. Galtayries, S. Zanna, L. Klein, V. Maurice, P. Jolivet, M. Foucault, P. Combrade, P. Scott, and P. Marcus, XPS and STM Study of the Growth and Structure of Passive Films in High Temperature Water on a Nickel-Base Alloy, Electrochim. Acta, 2004, 49, p 3957–3964

S.E. Ziemniak, M.E. Jones, and K.E.S. Combs, Solubility and Phase Behavior of Cr(III) Oxides in Alkaline Media at Elevated Temperatures, J. Solut. Chem., 1998, 27, p 33–66

Acknowledgments

This work was jointly supported by the Science Project of State Grid Corporation of China under Grant KG12K16004, the Science and Technology Project of Yunnan Province, the Technology Development (Cooperation) Fund from Yunnan Wenshan Dounan Manganese Industry Co., Ltd., and the Innovation Fund of Institute of Metal Research (IMR), Chinese Academy of Sciences (CAS).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wei, W., Wu, Xq., Ke, W. et al. Electrochemical Corrosion Behavior of Thermal-Sprayed Stainless Steel-Coated Q235 Steel in Simulated Soil Solutions. J. of Materi Eng and Perform 25, 518–529 (2016). https://doi.org/10.1007/s11665-016-1891-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-1891-0