Abstract

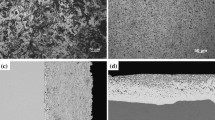

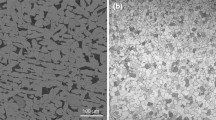

Electrochemical corrosion behavior of a thermal-sprayed Ni-Al-coated Q235 steel was investigated in the simulated soil solutions at different pH values using measurements of potentiodynamic polarization curves and electrochemical impedance spectroscopy as well as surface analyses including x-ray diffraction analysis, scanning electron microscope equipped with an energy-dispersive x-ray spectroscopy and x-ray photoelectron spectroscopy. The results showed that the corrosion resistance of the Ni-Al-coated Q235 steel was dependent on the pH of the test solution. From pH = 3.53 to pH = 4.79, the corrosion resistance of the coated steel increased rapidly. In the pH range from 4.79 to 12.26, the corrosion resistance exhibited no significant change. At pH 13.25, the corrosion resistance of the sample was found to decrease. The calculated corrosion rate of Ni-Al-coated Q235 steel was lower than that of the uncoated Q235 steel and galvanized steel in all the test solutions. Over a wide range of pH values, the Ni-Al-coated Q235 steel exhibited extremely good corrosion resistance. The experimental data together with the potential-pH diagrams provided a basis for a detailed discussion of the related corrosion mechanisms of the coated steel.

Similar content being viewed by others

References

M.C. Zheng, Z.N. Chen, and J.H. Li, Research on Corrosion Characteristics of Corrosion Rule and Anti-Corrosion Technology of Grounding Device for Large Substations, East China Electr. Power, 2009, 37, p 1463–1467

C.B. Ren, B. Feng, W.H. Zhou, and T.X. He, Corrosion of Grounding Network and Sacrificial Anode Protection, Hunan Electr. Power, 2003, 23, p 38–39

Y.L. Liu, Problems Existing in Earth Mats of Transformer Substations and the Countermeasures, Corros. Prot., 2007, 28, p 473–475

S.F. Li, Z.Z. Chen, M.F. Peng, and D.J. Yu, Corrosion Analysis and Anti-Corrosion Technology to Earthing Network System, Inn. Mong. Electr. Power, 2003, 21, p 9–12

J.K. Guo, J.S. Yu, L.Q. Lu, P. Zhao, and Z. Su, Evaluation on Effect of Cathode Protection for Galvanized Steel in Soil Environment, Inn. Mong. Electr. Power, 2013, 31, p 42–46

A.X. Guo, W.J. Hu, A.J. Yan, Z.Q. Yang, and L.J. Feng, Research of Corrosion Rule Grounding Materials of Stainless Steel and Galvanized Steel in Soil, Mater. Rev., 2015, 29, p 498–501

H. Zhang and C.W. Du, Corrosion Properties of Galvanized Auto Steel Sheet with Breakages of Zinc Coating in NaCl Containing Solution and Mud, Corros. Sci. Prot. Technol., 2009, 21, p 333–336

S. Papavinsasam, M. Attard, B. Arseneult, and R.W. Revie, State-of-the-Art of Thermal Spray Coatings for Corrosion Protection, Corros. Rev., 2008, 26, p 105–146

Z. Zeng, N. Sakoda, and T. Tajiri, Corrosion Behavior of Wire-Arc-Sprayed Stainless Steel Coating on Mild Steel, J. Therm. Spray Technol., 2006, 15, p 431–437

H.T. Cai, T. Jiang, and Y. Zhou, Research Status and Development of the Thermal Spray Technology, Equip. Manuf. Technol., 2014, 42, p 28–32

N. Cinca and J.M. Guilemany, Thermal Spraying of Transition Metal Aluminides: an Overview, Intermetallics, 2012, 24, p 60–72

J.T. Chang, C.H. Yeh, J.L. He, and K.C. Chen, Cavitation Erosion and Corrosion Behavior of Ni-Al Intermetallic Coatings, Wear, 2003, 255, p 162–169

Y. Wang, Y. Yang, and M.F. Yan, Microstructures, Hardness and Erosion Behavior of Thermal Sprayed and Heat Treated NiAl Coatings with Different Ceria, Wear, 2007, 263, p 371–378

K. Mehmood, M.A. Rafiq, A. Nusair Khan, F. Ahmed, and M. Mudassar Rauf, Characterization and Wear Behavior of Heat-treated Ni3Al Coatings Deposited by Air Plasma Spraying, J. Mater. Eng. Perform., 2016, 25, p 2752–2760

Y. Wang and W. Chen, Microstructures, Properties and High-Temperature Carburization Resistances of HVOF Thermal Sprayed NiAl Intermetallic-based Alloy Coatings, Surf. Coat. Technol., 2004, 183, p 18–28

C.G. Xu, L.Z. Du, B. Yang, and W.G. Zhang, The Effect of Al Content on the Galvanic Corrosion Behaviour of Coupled Ni/Graphite and Ni-Al Coatings, Corros. Sci., 2011, 53, p 2066–2074

S. Saladi, J.V. Menghani, and S. Prakash, Characterization and Evaluation of Cyclic Hot Corrosion Resistance of Detonation- Gun Sprayed Ni-5Al Coatings on Inconel-718, J. Therm. Spray Technol., 2015, 24, p 778–788

X.Q. Wu, J. Xu, W. Ke, S. Xu, B. Feng, and B.T. Hu, Effects of pH Value on Corrosion Behavior of Thermal-Sprayed Al-Si Coated Q235 Steel in Simulated Soil Solutions, J. Mater. Eng. Perform., 2014, 23, p 2265–2273

M. Serdar, L.V. Zulj, and D. Bjegovic, Long-Term Corrosion Behaviour of Stainless Reinforcing Steel in Mortar Exposed to Chloride Environment, Corros. Sci., 2013, 69, p 149–157

H. Luo, C.F. Dong, X.G. Li, and K. Xiao, The Electrochemical Behaviour of 2205 Duplex Stainless Steel in Alkaline Solutions with Different pH in the Presence of Chloride, Electrochim. Acta, 2012, 64, p 211–220

M. Liu, P. Schmutz, S. Zanna, A. Seyeux, H. Ardelean, G.L. Song, A. Atrens, and P. Marcus, Electrochemical Reactivity, Surface Composition and Corrosion Mechanisms of the Complex Metallic Alloy Al3Mg2, Corros. Sci., 2010, 52, p 562–578

M. Pourbaix, Atlas of Electrochemical Equilibria in Aqueous Solutions, National Association of Corrosion Engineers, Houston, 1974

D.S. Grzegorz and J. Pawel, Electrochemical Behaviour of Ni3Al-based Intermetallic Alloys in NaOH, Intermetallics, 2011, 19, p 974–981

W. Wei, X.Q. Wu, W. Ke, S. Xu, B. Feng, and B.T. Hu, Electrochemical Corrosion Behavior of Thermal-Sprayed Stainless Steel-Coated Q235 Steel in Simulated Soil Solutions, J. Mater. Eng. Perform., 2016, 25, p 518–529

Acknowledgments

This work was jointly supported by the Science and Technology Foundation of China (51371174), the Science Project of State Grid Corporation of China under Grant KG12K16004, and the Innovation Fund of IMR, CAS.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wei, W., Wu, Xq., Ke, W. et al. Relationship Between pH and Electrochemical Corrosion Behavior of Thermal-Sprayed Ni-Al-Coated Q235 Steel in Simulated Soil Solutions. J. of Materi Eng and Perform 26, 4340–4348 (2017). https://doi.org/10.1007/s11665-017-2906-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2906-1