Abstract

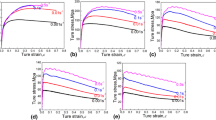

The flow stress behaviors of both the as-cast and homogenized Mg-8Gd-3Y-1Nd-0.5Zr alloy were investigated using a Gleeble-1500 thermal simulation test machine in the temperature range of 460-520 °C and strain rate range of 0.001-1 s−1. The processing maps for the two alloys were developed on the basis of flow stress data obtained at a strain of 0.5. It was found that the processing maps of both the as-cast alloy and homogenized alloy consisted of one stability and one instability domains. According to the processing maps and the microstructural observations, the optimum hot-working parameters for the two alloys were determined to be at a temperature of 500 °C and at a strain rate of 0.01 s−1. The hot workability of the homogenized alloy was better than the as-cast alloy in the safe domain, while the homogenization treatment increased the instability domain. The microvoids, which initiated along the dynamic recrystallized (DRX) grain boundaries and led to intercrystalline cracking, were an important factor contributing to the expanded instability domains for the homogenized alloy. Dynamic precipitation in the DRX grain in the as-cast alloy contributed to a lower DRX, hence prevented the formation of microvoids, which resulted in a reduced tendency for DRX intercrystalline cracking during hot deformation.

Similar content being viewed by others

References

M. Chandrasekaran and Y.M.S. John, Effect of Materials and Temperature on the Forward Extrusion of Magnesium Alloys, Mater. Sci. Eng. A, 2004, 38, p 308–319

Q. Guo, H.G. Yan, H. Zhang, Z.H. Chen, and Z.F. Wang, Behaviour of AZ31 Magnesium Alloy During Compression at Elevated Temperatures, Mater. Sci. Technol., 2005, 21, p 1349–1354

M.M. Myshlyaev, H.J. McQueen, A. Mwembela, and E. Konopleva, Twinning, Dynamic Recovery and Recrystallization in Hot Worked Mg-Al-Zn Alloy, Mater. Sci. Eng. A, 2002, 337, p 121–133

C. Antion, P. Donnadieu, F. Perrard, A. Deschamps, C. Tassin, and A. Pisch, Hardening Precipitation in a Mg-4Y-3RE Alloy, Acta Mater., 2003, 51, p 5335–5348

B. Chen, D. Lin, X. Zeng, and C. Lu, Effects of Yttrium and Zinc Addition on the Microstructure and Mechanical Properties of Mg-Y-Zn Alloys, J. Mater. Sci., 2010, 45, p 2510–2517

L. Zheng, C.M. Liu, J. Jin, X. Wang, and D.W. Ji, Effect of Hot Rolling on Microstructures and Mechanical Properties of Extruded Mg-6Gd-3.2Y-xZn-0.5Zr Sheet, J. Mater. Eng. Perform., 2013, 22, p 104–111

X. Xia, Q. Chen, K. Zhang, Z. Zhao, M. Ma, X. Li, and Y. Li, Hot Deformation Behavior and Processing Map of Coarse-Grained Mg-Gd-Y-Nd-Zr Alloy, Mater. Sci. Eng. A, 2013, 587, p 283–290

X. Xia, K. Zhang, X. Li, M. Ma, and Y. Li, Microstructure and Texture of Coarse-Grained Mg-Gd-Y-Nd-Zr Alloy After Hot Compression, Mater. Des., 2013, 44, p 521–527

X. Xia, Q. Chen, Z. Zhao, M. Ma, X. Li, and K. Zhang, Microstructure, Texture and Mechanical Properties of Coarse-Grained Mg-Gd-Y-Nd-Zr Alloy Processed by Multidirectional Forging, J. Alloys Compd., 2015, 623, p 62–68

Y.V.R.K. Prasad and K.P. Rao, Effect of Homogenization on the Hot Deformation Behavior of Cast AZ31 Magnesium Alloy, Mater. Des., 2009, 30, p 3723–3730

M. Mu, Z. Zhi-Min, Z. Bao-Hong, and D. Jin, Flow Behaviors and Processing Maps of As-Cast and As-Homogenized AZ91 Alloy, J. Alloys Compd., 2012, 513, p 112–117

Q.Z. Peng, H.T. Zhou, F.H. Zhong, H.B. Ding, X. Zhou, R.R. Liu, T. Xie, and Y. Peng, Effects of Homogenization Treatment on the Microstructure and Mechanical Properties of Mg-8Li-3Al-Y Alloy, Mater. Des., 2015, 66, p 566–574

C. Xu, M.Y. Zheng, S.W. Xu, K. Wu, E.D. Wang, S. Kamado, and G.J. Wang, Microstructures and Mechanical Properties of High-Strength Mg-Gd-Y-Zn-Zr Alloy Sheets Processed by Severe Hot Rolling, J. Alloys Compd., 2012, 528, p 40–44

Z. Yang, J.P. Li, J.X. Zhang, Y.C. Guo, B.W. Wang, F. Xia, and M.X. Liang, Effect of Homogenization on the Hot-Deformation Ability and Dynamic Recrystallization of Mg-9Gd-3Y-0.5Zr Alloy, Mater. Sci. Eng. A, 2009, 515, p 102–107

K.P. Rao, Y.V.R.K. Prasad, K. Suresh, N. Hort, and K.U. Kainer, Hot Deformation Behavior of Mg-2Sn-2Ca Alloy in As-Cast Condition and After Homogenization, Mater. Sci. Eng. A, 2012, 552, p 444–450

Y.V.R.K. Prasad, Processing Maps for Hot Working of Titanium Alloys, Mater. Sci. Eng. A, 1998, 243, p 82–88

O. Sivakesavam, I.S. Rao, and Y.V.R.K. Prasad, Processing Maps for Hot Working of As Cast Magnesium, Mater. Sci. Technol., 1993, 9, p 805–810

Y.V.R.K. Prasad and K.P. Rao, Mechanisms of High Temperature Deformation in Electrolytic Copper in Extended Ranges of Temperature and Strain Rate, Mater. Sci. Eng. A, 2004, 374, p 335–341

M. Li, K. Zhang, X. Li, Y. Li, M. Ma, G. Shi, J. Yuan, T. Li, and J. Liu, The Research of Microstructure and Mechanical Properties of Mg-7Gd-3Y-1Nd-0.5Zn-0.5Zr (wt.%) Alloy, Mater. Sci. Eng. A, 2015, 626, p 415–422

S. He, X. Zeng, L. Peng, X. Gao, J. Nie, and W. Ding, Microstructure and Strengthening Mechanism of High Strength Mg-10Gd-2Y-0.5Zr Alloy, J. Alloys Compd., 2007, 427, p 316–323

D.H.J. Li and X.Q. Zeng, Characterization of β″ Precipitate Phase in a Mg-Dy-Gd-Nd Alloy, Mater Charact., 2007, 58, p 1025–1028

I.A. Anyanwu, S. Kamado, and Y. Kojima, Creep Properties of Mg-Gd-Y-Zr Alloys, Mater. Trans., 2001, 42, p 1212–1218

Q. Li, Q. Wang, H. Zhou, X. Zeng, Y. Zhang, and W. Ding, High Strength Extruded Mg-5Zn-2Nd-1.5Y-0.6Zr-0.4Ca Alloy Produced by Electromagnetic Casting, Mater. Lett., 2005, 59, p 2549–2554

Y.J. Wu, X.Q. Zeng, D.L. Lin, L.M. Peng, and W.J. Ding, The Microstructure Evolution with Lamellar 14H-Type LPSO Structure in an Mg 96.5 Gd 2.5 Zn 1 Alloy During Solid Solution Heat Treatment at 773 K, J. Alloy. Compd., 2009, 477, p 193–197

D.D. Yin, Q.D. Wang, and Y. Gao, Effects of Heat Treatments on Microstructure and Mechanical Properties of Mg-11Y-5Gd-2Zn-0.5Zr (wt.%) alloy, J. Alloy. Compd., 2011, 509, p 1696–1704

C. Antion, P. Donnadieu, F. Perrard, A. Deschamps, C. Tassin, and A. Pisch, Hardening Precipitation in a Mg-4Y-3RE Alloy, Acta Mater., 2003, 51, p 5335–5348

Y. Yang, Z. Zhang, and X. Zhang, Processing Map of Al2O3 Particulate Reinforced Al Alloy Matrix Composites, Mater. Sci. Eng. A, 2012, 558, p 112–118

Y. Yang, Z. Zhang, X. Li, Q. Wang, and Y. Zhang, The Effects of Grain Size on the Hot Deformation and Processing Map for 7075 Aluminum Alloy, Mater. Des., 2013, 51, p 592–597

Y. Yang, Z. Xie, Z. Zhang, X. Li, Q. Wang, and Y. Zhang, Processing Maps for Hot Deformation of the Extruded 7075 Aluminum Alloy Bar: Anisotropy of Hot Workability, Mater. Sci. Eng. A, 2014, 615, p 183–190

B. Chen, W.-M. Zhou, S. Li, X.-L. Li, and C. Lu, Hot Compression Deformation Behavior and Processing Maps of Mg-Gd-Y-Zr Alloy, J. Mater. Eng. Perform., 2013, 22, p 2458–2466

J.A. Yasi, L.G. Hector, Jr., and D.R. Trinkle, First-Principles Data for Solid-Solution Strengthening of Magnesium: From Geometry and Chemistry to Properties, Acta Mater., 2010, 58, p 5704–5713

Y.P. Fan, Q.M. Peng, J.L. Pan, G.L. Bi, and B.Z. Liu, Strengthening Precipitate, Thermal Stability, and Mechanical Properties of Melt-Spun Mg-8Gd-3Nd Alloy, J. Mater. Eng. Perform., 2014, 23, p 250–254

M. Yamasaki, T. Anan, S. Yoshimoto, and Y. Kawamura, Mechanical Properties of Warm-Extruded Mg-Zn-Gd Alloy with Coherent 14H Long Periodic Stacking Ordered Structure Precipitate, Sci. Mater., 2005, 53, p 799–803

Y. Xue, Z. Zhang, G. Lu, Z. Xie, Y. Yang, and Y. Cui, Study on Flow Stress Model and Processing Map of Homogenized Mg-Gd-Y-Zn-Zr Alloy During Thermomechanical Processes, J. Mater. Eng. Perform., 2015, 24, p 964–971

Acknowledgment

The project was supported by Program for New Century Excellent Talents in University (NCET-13-1001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qin, Q., Tan, Y., Zhang, Z. et al. Effects of Homogenization on Hot Deformation Behavior of As-Cast Mg-8Gd-3Y-1Nd-0.5Zr Magnesium Alloy. J. of Materi Eng and Perform 25, 304–311 (2016). https://doi.org/10.1007/s11665-015-1807-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1807-4