Abstract

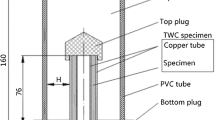

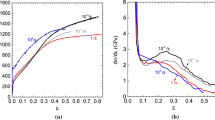

Dynamic shear test was conducted on the hat-shaped specimen of the thermo-mechanical-processed 1Cr18Ni9Ti stainless steel by using the split Hopkinson pressure bar at ambient temperature. The effect of the shear strain on the microstructure evolution was investigated during adiabatic shearing. The results revealed that the development of adiabatic shear localization went through three stages, including the incubation period, the development stage, and the maturity period. TEM observations showed that the grains in the shear region were elongated, and the elongated grains were gradually evolved into equiaxed nano-grains of 100 nm as shear strain increased. The rotational dynamic recrystallization kinetics calculation showed that subgrains had sufficient time to generate an equiaxed microcrystalline structure by rotation within the deformation time. Based on the observation of the evolution of dislocations and sub-grains in the adiabatic shear region, a model of the microstructure evolution was established during the adiabatic shearing.

Similar content being viewed by others

References

Q. Xue, J.F. Bingert, B.L. Henrie, and G.T. Gray, III, EBSD characterization of dynamic shear band regions in pre-shocked and as-received 304 stainless steels, Mater. Sci. Eng. A, 2008, 473(1-2), p 279–289

M.A. Meyers, Dynamic behavior of materials, 1st ed., Wiley, New York, 1994, p 1–19

Y. Yang and B.F. Wang, Dynamic recrystallization in adiabatic shear band in α-titanium, Mater. Lett., 2006, 60(17-18), p 2198–2202

B.F. Wang and Y. Yang, Microstructure evolution in adiabatic shear band in fine-grain-sized Ti-3Al-5Mo-4.5V alloy, Mater. Sci. Eng. A, 2008, 473(1-2), p 306–311

Y. Yang, F. Jiang, B.M. Zhou, X.M. Li, H.G. Zheng, and Q.M. Zhang, Microstructural characterization and evolution mechanism of adiabatic shear band in a near beta-Ti alloy, Mater. Sci. Eng. A, 2011, 528(6), p 2787–2794

Y. Yang, Y. Zeng, D.H. Li, and M. Li, Damage and fracture mechanism of aluminium alloy thick-walled cylinder under external explosive loading, Mater. Sci. Eng. A, 2008, 490(1-2), p 378–384

E. El-Magd and M. Abouridouane, Characterization, modelling and simulation of deformation and fracture behaviour of the light-weight wrought alloys under high strain rate loading, Int. J. Impact Eng., 2006, 32(5), p 741–758

M.A. Meyers, Y.B. Xu, Q. Xue, M.T. Perez-Prado, and T.R. McNelley, Microstructural evolution in adiabatic shear localization in stainless steel, Acta Mater., 2003, 51(5), p 1307–1325

Q. Xue and G.T. Gray, III, Development of adiabatic shear bands in annealed 316L stainless steel: part I. Correlation between evolving microstructure and mechanical behavior, Metall. Mater. Trans. A, 2006, 37(8), p 2435–2446

J.F.C. Lins, H.R.Z. Sandim, H.J. Kestenbach, D. Raabe, and K.S. Vecchio, A microstructural investigation of adiabatic shear bands in an interstitial free steel, Mater. Sci. Eng. A, 2007, 457(1-2), p 205–218

U. Andrade, M.A. Meyers, K.S. Vecchio, and A.H. Chokshi, Dynamic recrystallization in high-strain, high-strain-rate plastic deformation of copper, Acta Metall. et Mater., 1994, 42(9), p 3183–3195

D.H. Li, Y. Yang, T. Xu, H.G. Zheng, Q.S. Zhu, and Q.M. Zhang, Observation of the microstructure in the adiabatic shear band of 7075 aluminum alloy, Mater. Sci. Eng. A, 2010, 527(15), p 3529–3535

Q. Xue, E.K. Cerreta, and G.T. Gray, III, Microstructural characteristics of post-shear localization in cold-rolled 316L stainless steel, Acta Mater., 2007, 55(2), p 691–704

Q. Xue and G.T. Gray, III, Development of adiabatic shear bands in annealed 316L stainless steel: part II. TEM studies of the evolution of microstructure during deformation localization, Metall. Mater. Trans. A, 2006, 37(8), p 2447–2458

J.A. Hines and K.S. Vecchio, Recrystallization kinetics within adiabatic shear bands, Acta Mater., 1997, 45(2), p 635–649

R.S. Culver, Thermal instability strain in dynamic plastic deformation, metallurgical effects at high strain rates, Springer, New York, 1973, p 519–530

H. Wu, Z. Zeng, N. Guo, X. Zhang, T. Lei, and J. Han, Experimental study on the current loss of MITL With cathode made of different stainless steel, IEEE Trans. Plast. Mater. Sci., 2012, 40(4), p 1177–1182

Acknowledgments

This work is supported by the National Natural Science Foundation of China (No. 51274245), NSAF (No. U1330126), the Ph.D. Programs Foundation of Ministry of Education of China (No. 20120162130006), the key project of State Key Laboratory of Explosion Science and Technology (No. KFJJ11-1), and the Natural Science Fund of Hunan (No. 14 jj2011).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, Y., Jiang, L.H., Luo, S.H. et al. Effect of Strain on Microstructure Evolution of 1Cr18Ni9Ti Stainless Steel During Adiabatic Shearing. J. of Materi Eng and Perform 25, 29–37 (2016). https://doi.org/10.1007/s11665-015-1776-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1776-7