Abstract

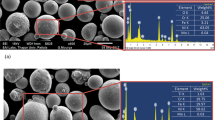

Susceptibility of SA-543 steel, its welds (with and without stress relief treatment), and the heat-affected zone (HAZ) to stress corrosion cracking (SCC) was investigated in de-aerated and aerated boiler feed water subjected to the all-volatile treatment (AVT-BFW), and distilled water at 275 °C using the slow strain rate testing (SSRT) technique. The SSRT specimens were tested at three extension rates (3.50 × 10−6, 9.00 × 10−6, and 7.50 × 10−5 mm/s) using a novel SCC testing rig capable of testing at high temperatures and pressures. There are no significant differences in the time-to-failure among the four tested specimens. The elongation of the specimens at the time of failure is in the range of 10-23%. The reduction of the cross-sectional area of the failed specimens is large (45-77%) and the absence of any signs of intergranular propagation in fractured specimens, determined by scanning electron microscopy, indicates that the failure is due to mechanical load and not due to SCC. Dissolved oxygen does not affect the susceptibility of the specimens to SCC, which could be due to the inhibition effect of the test solution. SA-543 steel as the base metal, its welds (with and without stress relief treatment), and the HAZ are suitable for use in hot AVT-BFW and distilled water.

Similar content being viewed by others

References

M. Al-Mansour, A.M. Alfantazi, and M. El-boujdaini, Sulfide stress cracking resistance of API-X100 high strength low alloy steel, Mater. Des., 2009, 30, p 4088–4094

R. Rihan, R.K. Singh Raman, R. N. Ibrahim, and D. Gerrard, Determination of the Threshold Stress Intensity Factor (KIscc) of 4340 Steel Using Small Circumferential Notched Tensile (CNT) Specimens, Corrosion & Prevention 2006 “Steel & Concrete—Nothing Lasts Forever”, Hobart, Australia, 2006.

R.K. Singh Raman, R. Rihan, and R.N. Ibrahim, Validation of a novel approach to determination of threshold for stress corrosion cracking (KIscc), Mater. Sci. Eng. A, 2007, 452–453, p 652–656

S. Pal and R.K. Singh Raman, Determination of threshold stress intensity for chloride stress corrosion cracking of solution-annealed and sensitized austenitic stainless steel by circumferential notch tensile technique, Corros. Sci., 2010, 52, p 1985–1991

R.N. Ibrahim, R. Rihan, and R.K. Singh Raman, Validity of a new fracture mechanics technique for the determination of the threshold stress intensity factor for stress corrosion cracking (KIscc) and crack growth rate of engineering materials, Eng. Fract. Mech., 2008, 75, p 1623–1634

R. Rihan, R.K. Singh Raman, and R.N. Ibrahim, Circumferential notched tensile (CNT) testing of cast iron for determination of threshold (KIscc) for caustic crack propagation, Mater. Sci. Eng. A, 2005, 407, p 207–212

R. Rihan, R.K. Singh Raman, and R.N. Ibrahim, Determination of crack growth rate and threshold for caustic cracking (KIscc) of a cast iron using small circumferential notched tensile (CNT) specimens, Mater. Sci. Eng. A, 2006, 425, p 272–277

R.K. Singh Raman and B.C. Muddle, Stress corrosion cracking of vessels and pipes for alumina processing in aggressive caustic solutions, Int. J. Press. Vessel. Pip., 2004, 81, p 557–561

R.K. Singh Raman and B.C. Muddle, Caustic stress corrosion cracking of a spheroidal graphite cast iron: characterisation of ex-service component, Mater. Sci. Technol., 2003, 19, p 1746–1750

D.C. Bennett, Continuous digester cracking task group reports on past year’s efforts, Tappi J., 1981, 64, p 75–77

D.C. Bennett, Cracking in continuous digesters, history of the problem and research for preventive measures, Tappi J., 1982, 65, p 43–45

D.C. Bennett, Pulp and Paper Industry Corrosion Problems, Vol 4, Swedish Corrosion Institute, Stockholm, 1983, p 1

D.G. Friend and R.B. Dooley, Technical Guidance Document: Volatile Treatments for the Steam-Water Circuits of Fossil and Combined Cycle/HRSG Power Plants, The International Association for the Properties of Water and Steam, Niagara Falls, 2010

K. Ranjbar, Failure analysis of boiler cold and hot reheater tubes, Eng. Fail. Anal., 2007, 14, p 620–625

W.E. Bornak, Chemistry of iron and its corrosion products in boiler systems, Corrosion, 1988, 44, p 154–158

Y. Zuo, H. Wang, J. Zhao, and J. Xiong, The effects of some anions on metastable pitting of 316L stainless steel, Corros. Sci., 2002, 44, p 13

R.K. Singh Raman and W.H. Siew, Role of nitrite addition in chloride stress corrosion cracking of a super duplex stainless steel, Corros. Sci., 2010, 52, p 113

O. Horner, E.M. Pavageau, F. Vaillant, O. Bouvier, Laboratory results of stress corrosion cracking of steam generator tubes in a “complex” environment—an update, EUROCORR 2004: long term prediction and modeling of corrosion, Nice, France, 2004.

R.C. Newman and T. Shahrabi, The effect of alloyed nitrogen or dissolved nitrate ions on the anodic behaviour of austenitic stainless steel in hydrochloric acid, Corros. Sci., 1987, 27, p 827

R.C. Newman and M.A.A. Ajjawi, A micro-electrode study of the nitrate effect on pitting of stainless steels, Corros. Sci., 1986, 26, p 1057

H.H. Uhlig and J.E.W. Cook, Mechanism of inhibiting stress corrosion cracking of 18-8 stainless steel in MgCl2 by acetates and nitrates, J. Electrochem. Soc., 1969, 116, p 173

H.P. Leckie and H.H. Uhlig, Environmental factors affecting the critical potential for pitting in 18-8 stainless steel, J. Electrochem. Soc., 1966, 113, p 1262

R.L. Jones, Nitrate effects promoting the stress corrosion cracking of AISI, type 304 stainless steel in MgCl2 above 200 C, Corrosion, 1975, 31, p 431

H. Hirano, N. Aoki, and T. Kurosawa, The effect of dissolved oxygen and NO3 − anions on the stress corrosion cracking of type 304 stainless steel in water at 290 C, Corrosion, 1983, 39, p 314

S.A.M. Refaey, S.S.A. El-Rehim, F. Taha, M.B. Saleh, and R.A. Ahmed, Inhibition of chloride localized corrosion of mild steel by PO4 3−, CrO4 2−, MoO4 2−, and NO2 − anions, Appl. Surf. Sci., 2000, 158, p 190

V.K. Gouda and S.M. Sayed, Corrosion behaviour of steel in solutions containing mixed inhibitive and aggressive ions, Corros. Sci., 1973, 13, p 841

R. Rihan, M. Qubbaj, M. Basha, L. Al-Hadhrami, Stress Corrosion Cracking Testing Device, Patent Number: US 8474324 B2, 2nd July 2013.

J. Congleton and R.N. Parkins, Stress corrosion cracking of steel in high temperature water, Corrosion, 1988, 44, p 290–298

M.J. Fountain, Two-Phase Erosion-Corrosion Studies at CEGB, North Western Region, Water Chemistry 3, British Nuclear Energy Society, London, 1983, p 385–386

H.G. Heitmann and P. Schub, Initial Experience Gained With a High pH Value in the Secondary System of PWRs, Water Chemistry 3, BNES, London, 1983, p 243–252

H.G. Heitmann, Handbook of Power Plant Chemistry, CRC Press Inc., New York, 1993, p 376–379

M.F. Elisabeth and D.R. Holmes, Nucleation and growth of magnetite films on pure iron in high temperature water, Corros. Sci., 1965, 5, p 362

W.A. Ghanem, F.M. Bayyoumi, and B.G. Ateya, The high temperature corrosion of a low alloy steel in aqueous sodium chloride, Corros. Sci., 1996, 38, p 1171–1186

D. Singbeil and D. Tromans, Effect of sulfide ions on caustic cracking of mild steel, J. Electrochem. Soc., 1981, 128, p 2065–2070

D. Singbeil and D. Tromans, Caustic stress corrosion cracking of mild steel, Metall. Mater. Trans. A, 1982, 13A, p 1091–1098

D. Singbeil and D. Tromans, A fracture mechanics study of caustic cracking of mild steel in hot NaOH/Na2S solutions, J. Electrochem. Soc., 1982, 129, p 2669–2673

S.R. Bala and D. Tromans, Stress corrosion cracking of high strength HY-180M steel in 3.5 Pct NaCl, Metall. Mater. Trans. A, 1978, 9A, p 1125–1132

Acknowledgment

The authors would like to acknowledge the Center for Engineering Research/Research Institute at King Fahd University of Petroleum & Minerals for conducting the research and Saudi Basic Industries Corporation (SABIC) for supporting this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rihan, R., Basha, M., Al-Meshari, A. et al. Stress Corrosion Cracking of SA-543 High-Strength Steel in All-Volatile Treatment Boiler Feed Water. J. of Materi Eng and Perform 24, 3773–3782 (2015). https://doi.org/10.1007/s11665-015-1681-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1681-0