Abstract

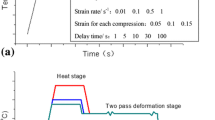

The deformation process and inter-pass time of hot working are always accompanied by complicated microstructural evolution. As a kind of low alloy steels with good malleability, Q345E steel is widely used. The specimens of Q345E steel were heated to 1123, 1223, 1323, 1423, and 1523 K and held for 0, 120, 240, 360, and 480 s, respectively, on Gleeble-3500 thermo-mechanical simulator to develop the austenite grain growth equation of Q345E steel. In addition, the ‘single-pass hot compression tests,’ ‘double-pass hot compression tests,’ and ‘single-pass hot compression and thermal insulation tests’ at temperature from 1123 to 1423 K with the strain rate from 0.01 to 10 s−1 were carried out on Gleeble-3500 thermo-mechanical simulator to investigate the behavior of dynamic recrystallization (DRX), meta-dynamic recrystallization (MDRX), and static recrystallization (SRX), and to establish the mathematical equations of DRX, MDRX, and SRX, which can predict the volume fraction of recrystallization and grain size after recrystallization. The result of error analysis and a 2D finite element simulation model during hot upsetting verifies that the experimental data agree well with the predicted values calculated by these mathematical equations, which indicates that the established mathematical equations can be applied to accurately predict the microstructural evolution of Q345E steel during hot deformation.

Similar content being viewed by others

References

J. Lin and T.A. Dean, Modelling of Microstructure Evolution in Hot Forming Using Unified Constitutive Equations, J. Mater. Process. Technol., 2005, 167, p 354–362

W.X. Wu, L. Jin, F.H. Wang, J. Sun, Z.Y. Zhang, W.J. Ding, and J. Dong, Microstructure and Texture Evolution During Hot Rolling and Subsequent Annealing of Mg-1Gd Alloy, Mater. Sci. Eng. A, 2013, 582, p 194–202

N. Bontcheva and G. Petzov, Total Simulation Model of the Thermo-Mechanical Process in Shape Rolling of Steel Rods, Comput. Mater. Sci., 2005, 34, p 377–388

Y.C. Lin, Y. Ding, M.S. Chen, and J. Deng, A New Phenomenological Constitutive Model for Hot Tensile Deformation Behaviors of a Typical Al-Cu-Mg Alloy, Mater. Des., 2013, 52, p 118–127

B. Zou, Z.Q. Chen, C.H. Liu, and J.H. Chen, Microstructure Evolution of Heavily Deformed AA5083 Al-Mg Alloy Studied by Positron Annihilation Spectroscopy, Appl. Surf. Sci., 2014, 296, p 154–157

H. Hallberg, B. Svendsen, T. Kayser, and M. Ristinmaa, Microstructure Evolution During Dynamic Discontinuous Recrystallization in Particle-Containing Cu, Comput. Mater. Sci., 2014, 84, p 327–338

Y. Liu and J. Lin, Modelling of Microstructural Evolution in Multipass Hot Rolling, J. Mater. Process. Technol., 2003, 143-144, p 723–728

G.Z. Quan, A. Mao, G.C. Luo, J.T. Liang, D.S. Wu, and J. Zhou, Constitutive Modeling for the Dynamic Recrystallization Kinetics of as-Extruded 3Cr20Ni10W2 Heat-Resistant Alloy Based on Stress-Strain Data, Mater. Des., 2013, 52, p 98–107

Y. Xu, L.X. Hu, and Y. Sun, Deformation Behaviour and Dynamic Recrystallization of AZ61 Magnesium Alloy, J. Alloys Compd., 2013, 580, p 262–269

F. Yin, L. Hua, H.J. Mao, X.H. Han, D.S. Qian, and R. Zhang, Microstructural Modeling and Simulation for GCr15 Steel During Elevated Temperature Deformation, Mater. Des., 2014, 55, p 560–573

P. Bernard, S. Bag, K. Huang, and R.E. Logé, A Two-Site Mean Field Model of Discontinuous Dynamic Recrystallization, Mater. Sci. Eng. A, 2011, 528, p 7357–7367

H.Q. Liang, H.Z. Guo, Y.Q. Ning, X.N. Peng, C. Qin, Z.F. Shi, and Y. Nan, Dynamic Recrystallization Behavior of Ti-5Al-5Mo-5V-1Cr-1Fe Alloy, Mater. Des., 2014, 63, p 798–804

M. Toloui and S. Serajzadeh, Modelling Recrystallization Kinetics During Hot Rolling of AA5083, J. Mater. Process. Technol., 2007, 184, p 345–353

Q.Y. Sha, G.Y. Li, and D.H. Li, Static Recrystallized Grain Size of Coarse-Grained Austenite in an API-X70 Pipeline Steel, J. Mater. Eng. Perform., 2013, 22, p 3626–3630

A.M. Elwazri, P. Wanjara, and S. Yue, Metadynamic and Static Recrystallization of Hypereutectoid Steel, ISIJ Int., 2003, 43(7), p 1080–1088

Y. Fu and H. Yu, Application of Mathematical Modeling in Two-Stage Rolling of Hot Rolled Wire Rods, J. Mater. Process. Technol., 2014, 214, p 1962–1970

G.W. Yang, X.J. Sun, Q.L. Yong, Z.D. Li, and X.X. Li, Austenite Grain Refinement and Isothermal Growth Behavior in a Low Carbon Vanadium Microalloyed Steel, J. Iron. Steel Res. Int., 2014, 21(8), p 757–764

B. Zhu, Y.S. Zhang, C. Wang, P.X. Liu, and W.K. Liang, Modeling of the Austenitization of Ultra-High Strength Steel with Cellular Automation Method, Metall. Mater. Trans. A, 2014, 45A, p 3161–3171

A.H. Seikh, M.S. Soliman, A. AlMajid, K. Alhajeri, and W. Alshalfan, Austenite Grain Growth Kinetics in API X65 and X70 Line-Pipe Steels During Isothermal Heating, Adv. Mater. Sci. Eng., 2014, 2014, p 1–8.

F.L. Sui, Y. Zuo, X.H. Liu, and L.Q. Chen, Microstructure Analysis on IN 718 Alloy Round Rod by FEM in the Hot Continuous Rolling Process, Appl. Math. Model., 2013, 37, p 8776–8784

C. Wu, H. Yang, and H.W. Li, Modeling of Discontinuous Dynamic Recrystallization of a Near-a Titanium Alloy IMI834 During Isothermal Hot Compression by Combining a Cellular Automaton Model with a Crystal Plasticity Finite Element Method, Comput. Mater. Sci., 2013, 79, p 944–959

C.M. Sellars and J.A. Whiteman, Recrystallization and Grain Growth in Hot Rolling, Met. Sci., 1979, 13(3-4), p 187–194

J.T. Yeom, C.S. Lee, J.H. Kim, and N.K. Park, Finite-Element Analysis of Microstructure Evolution in the Cogging of an Alloy 718 Ingot, Mater. Sci. Eng. A, 2007, 449-451, p 722–726

C.P. Hong and J.J. Park, Design of Pass Schedule for Austenite Grain Refinement in Plate Rolling of a Plain Carbon Steel, J. Mater. Process. Technol., 2003, 143-144, p 758–763

D. Priadi, A.M. Napitupulu, and E.S. Siradj, Austenite Grain Growth Calculation of 0.028% Nb Steel, J. Min. Metall. Sect. B, 2011, 47(2), p 199–209

P.H. Romero, I. Lonardelli, D. Cogswell, and H.K.D.H. Bhadeshia, Austenite Grain Growth in a Nuclear Pressure Vessel Steel, Mater. Sci. Eng. A, 2013, 567, p 72–79

C.X. Yue, L.W. Zhang, S.L. Liao et al., Kinetic Analysis of the Austenite Grain Growth in GCr15 Steel, J. Mater. Eng. Perform., 2010, 19(1), p 112–115

Y.P. Li, T. Suzuki, N. Tang, Y. Koizumi, and A. Chiba, Microstructure Evolution of SUS303 Free-Cutting Steel During Hot Compression Process, Mater. Sci. Eng. A, 2013, 583, p 161–168

C.J. Wang, H. Feng, W.J. Zheng, and Q.L. Yong, Dynamic Recrystallization Behavior and Microstructure Evolution of AISI, 304 N Stainless Steel, J. Iron. Steel Res. Int., 2013, 20(10), p 107–112

G.L. Ji, Q. Li, and L. Li, The Kinetics of Dynamic Recrystallization of Cu-0.4 Mg Alloy, Mater. Sci. Eng. A, 2013, 586, p 197–203

G.Z. Quan, Y. Shi, Y.X. Wang, B.S. Kang, T.W. Ku, and W.J. Song, Constitutive Modeling for the Dynamic Recrystallization Evolution of AZ80 Magnesium Alloy Based on Stress-Strain Data, Mater. Sci. Eng. A, 2011, 528, p 8051–8059

S.D. Gu, L.W. Zhang, J.H. Ruan, P.Z. Zhou, and Y. Zhen, Constitutive Modeling of Dynamic Recrystallization Behavior and Processing Map of 38MnVS6 Non-quenched Steel, J. Mater. Eng. Perform., 2014, 23, p 1062–1068

C.X. Yue, L.W. Zhang, S.L. Liao, and H.J. Gao, Mathematical Models for Predicting the Austenite Grain size in Hot Working of GCr15 Steel, Comput. Mater. Sci., 2009, 45, p 462–466

J. Liu, Z. Cui, and L. Ruan, A New Kinetics Model of Dynamic Recrystallization for Magnesium Alloy AZ31B, Mater. Sci. Eng. A, 2011, 529, p 300–310

X.M. Chen, Y.C. Lin, D.X. Wen, J.L. Zhang, and M. He, Dynamic Recrystallization Behavior of a Typical Nickel-Based Superalloy During Hot Deformation, Mater. Des., 2014, 57, p 568–577

M.H. Wang, Y.F. Li, W.H. Wang, J. Zhou, and A. Chiba, Quantitative Analysis of Work Hardening and Dynamic Softening Behavior of low carbon alloy Steel Based on the Flow Stress, Mater. Des., 2013, 45, p 384–392

H.L. Wei, G.Q. Liu, X. Xiao, and M.H. Zhang, Dynamic Recrystallization Behavior of a Medium Carbon Vanadium Microalloyed Steel, Mater. Sci. Eng. A, 2013, 573, p 215–221

Y.G. Liu, M.Q. Li, and J. Luo, The Modelling of Dynamic Recrystallization in the Isothermal Compression of 300M Steel, Mater. Sci. Eng. A, 2013, 574, p 1–8

M.H. Maghsoudi, Z.A. Hanzaki, P. Changizian, and A. Marandi, Metadynamic Recrystallization Behavior of AZ61 Magnesium Alloy, Mater. Des., 2014, 57, p 487–493

H.Y. Wu, L.X. Du, Z.R. Ai, and X.H. Liu, Static Recrystallization and Precipitation Behavior of a Weathering Steel Microalloyed with Vanadium, J. Mater. Sci. Technol., 2013, 29(12), p 1197–1203

L. Cheng, H. Chang, B. Tang, H.C. Kou, and J.S. Li, Characteristics of Metadynamic Recrystallization of a High Nb Containing TiAl Alloy, Mater. Lett., 2013, 92, p 430–432

Y.G. Liu, J. Liu, M.Q. Li, and H. Lin, The Study on Kinetics of Static Recrystallization in the Two-Stage Isothermal Compression of 300M Steel, Comput. Mater. Sci., 2014, 84, p 115–121

S.Q. Bao, G. Zhao, C.B. Yu, Q.M. Chang, C.L. Ye, and X.P. Mao, Recrystallization Behavior of a Nb-microalloyed Steel During Hot Compression, Appl. Math. Model., 2011, 35, p 3268–3275

Q.Y. Sha, D.H. Li, and G.Y. Li, Dynamic and Static Recrystallization Behaviour of Coarse-Grained Austenite in a Nb-V-Ti Microalloyed-Steel, J. Iron. Steel Res. Int., 2014, 21(2), p 233–239

Y.C. Lin, M.S. Chen, and J. Zhong, Study of Static Recrystallization Kinetics in a Low Alloy Steel, Comput. Mater. Sci., 2008, 44, p 316–321

Y.C. Lin and M.S. Chen, Study of Microstructural Evolution During Static Recrystallization in a Low Alloy Steel, J. Mater. Sci., 2009, 44, p 835–842

Acknowledgments

The authors would like to thank the State Key Program of National Natural Science Foundation of China (No. 51135007), the Innovative Research Team Development Program of Ministry of Education of China (No. IRT13087), and the State Key Laboratory of Materials Processing and Die & Mould Technology, Huazhong University of Science and Technology (No. 2012-P08).

Author information

Authors and Affiliations

Corresponding author

Appendix

Rights and permissions

About this article

Cite this article

Qian, D., Peng, Y. Mathematical Modeling for Microstructural Evolution in Multi-pass Hot Compression of Q345E Alloy Steel. J. of Materi Eng and Perform 24, 1906–1917 (2015). https://doi.org/10.1007/s11665-015-1473-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1473-6