Abstract

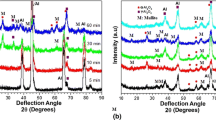

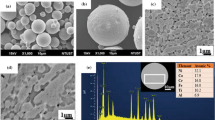

NiAl Plasma Transferred Arc coatings can be processed by in-situ synthesis of the aluminide during the deposition of mixtures of Ni and Al powders. This procedure allows to deposit compositions that otherwise would exhibit low weldability. The strong metallurgical bond of coatings involves the formation of a weld pool. It is therefore expected for the composition of the processed coatings to be influenced both by the deposited and base material, besides processing parameters. This study analyzed the impact of the deposition current on the point defect structure in the B2NiAl-ordered structure and consequently on the coating hardness and indentation modulus. Mixtures of 65 at.%Ni and 35 at.%Al were prepared and deposited on carbon steel and stainless steel plates. Deposition current ranging from 70 to 150 A was used to induce different Fe content in the coatings. Results showed that increasing deposition current increased dilution with substrate but contrary to observations on metallic coatings, an increase of hardness and indentation modulus was measured. The hypothesis that the measured behavior is related to the point defect structure of the ordered phase, B2-NiAl, is put forward. The Fe content determined the density and type of point defects: vacancies, anti-sites Al or Ni. A better understanding on the mechanisms controlling the properties of the aluminide PTA coatings with increasing deposition current is achieved: hardness exhibiting a direct correlation with the point defect structure and the indentation modulus a strong dependence on the microstructure.

Similar content being viewed by others

References

A.H. Jones and P. Roffey, The Improvement of Hard Facing Coatings for Ground Engaging Applications by the Addition of Tungsten Carbide, Wear, 2009, 267, p 925–933. doi:10.1016/j.wear.2009.01.006

F.J.R. Cangue and A.S.C.M. D’Oliveira, Influence of Al on the Microstructure and Carburization Performance of a N-Based Alloy Coating, Mater. Chem. Phys., 2010, 120, p 552–557. doi:10.1016/j.matchemphys.2009.11.046

A.E. Yaedu and A.S.C.M. D’Oliveira, Co Based Alloy PTA Hardfacing with Different Dilution Levels, Mater. Sci. Technol., 2005, 21, p 459–466. doi:10.1179/174328405X36511

V.B. Almeida, E.H. Takano, I. Mazzaro, and A.S.C.M. D’Oliveira, Evaluation of Ni-Al Coatings Processed by Plasma Transferred Arc, Surf. Eng., 2011, 27, p 266–271. doi:10.1179/026708410X12550773057866

A.S.C.M. D’Oliveira, E.H. Takano, L. Belloti, and R.P. Cardoso, Solidification of PTA Aluminide Coatings, Int. J. Mater. Res., 2012, 9, p 1159–1162. doi:10.3139/146.110773

L.M. Pike, Y.A. Chang, and C.T. Liu, Point Defect Concentrations and Hardening in Binary B2 Intermetallics, Acta Mater., 1997, 45, p 3709–3719. doi:10.1016/S1359-6454(97)00028-1

I.M. Anderson, A.J. Duncan, and J. Bentley, Site-Distributions of Fe Alloying Additions to B2-Ordered NiAl, Intermetallics, 1999, 7, p 1017–1024. doi:10.1016/S0966-9795(99)00013-8

L.M. Pike, Y.A. Chang, and C.T. Liu, Solid-Solution Hardening and Softening by Fe Additions to NiAl, Intermetallics, 1997, 5, p 601–608. doi:10.1016/S0966-9795(97)00040-X

International Organization for Standardization. ISO/FDIS 14577-1 Metallic Materials – Instrumented Indention Test for Hardness and Materials Parameters, 2002, p 1–25.

American Society for Metals, Properties and Selection: Irons, Steels, and High-Performance Alloys, Metals Handbook, vol. 1, 1994, p 2521.

K.R.A. Ziebeck and K.U. Neumann, Alloys and Compounds of d-Elements with Main Group Elements, Part 2, Landolt-Börnstein: Group III, Condens. Matter, 2001, 32, p 69–72. doi:10.1007/b59342

R. Hu, H.N. Su, and P. Nash, Enthalpies of Formation and Lattice Parameters of B2 Phases in Al-Ni-X Systems P, Pure Appl. Chem., 2007, 9, p 1653–1673. doi:10.1351/pac200779101653

J.D. Cotton, R.D. Noebe, and M.J. Kaufman, The Effects of Chromium on NiAl Intermetallic Alloys: Part I, Microstruct. Mech. Proper. Intermet., 1993, 1, p 3–20. doi:10.1016/0966-9795(93)90016-O

C.R. Kao, L.M. Pike, S.L. Chen, and Y.A. Chang, Site Preference of Substitutional Additions to Triple-Defect B2 Intermetallic Compounds, Intermetallics, 1994, 2, p 235–247. doi:10.1016/0966-9795(94)90010-8

G.H. Bozzolo, R.D. Noebe, and C. Amador, Site Occupancy of Ternary Additions to B2 Alloys, Intermetallics, 2002, 10, p 149–159. doi:10.1016/S0966-9795(01)00124-8

C.R.A. Silva, Jr, and G. Pintaude, Uncertainty Analysis on the Wear Coefficient of Archard Model, Tribol. Int., 2008, 41, p 473–481. doi:10.1016/j.triboint.2007.10.007

V. Ramasubbu, G. Chakraborty, S.K. Albert, and A.K. Bhaduri, Effect of Dilution on GTAW Colmonoy 6 (AWS NiCr-C) Hardface Deposit Made on 316LN Stainless Steel, Mater. Sci. Technol., 2011, 27, p 573–580. doi:10.1179/026708309X12526555493431

A. Albiter, E. Bedolla, and R. Perez, Microstructure Characterization of the NiAl Intermetallic Compound with Fe, Ga and Mo Additions Obtained by Mechanical Alloying, Mater. Sci. Eng. A, 2002, 328, p 80–86. doi:10.1016/S0921-5093(01)01664-1

S.C. Deevi, V.K. Sikka, and C.T. Liu, Processing, Properties, and Applications of Nickel and Iron Aluminides, Progress Mater. Sci., 1997, 2, p 177–192. doi:10.1016/0966-9795(95)00056-9

G.P. Cammarota and A.J. Casagrande, Effect of Ternary Additions of Iron on Microstructure and Microhardness of the Intermetallic NiAl in Reactive Sintering, Alloys Compd., 2004, 381, p 208–214. doi:10.1016/j.jallcom.2004.04.077

G. Frommeyer, R. Rablbauer, and H.J. Schafer, Elastic Properties of B2-Ordered NiAl and NiAl-X (Cr, Mo, W) alloys, Intermetallics, 2010, 18, p 299–305. doi:10.1016/j.intermet.2009.07.026

C. Li, Y.L. Chin, and P. Wu, Correlation Between Bulk Modulus of Ternary Intermetallic Compounds and Atomic Properties of Their Constituent Elements, Intermetallics, 2004, 12, p 103–109. doi:10.1016/j.intermet.2003.08.003

A.R. Miedema, P.F. De Châtel, and R. De Boer, Cohesion in Alloys: Fundamentals of a Semi-Empirical Model, Physica B, 1980, 100, p 1–28. doi:10.1016/0378-4363(80)90054-6

X.Q. Chen, H. Niu, D. Li, and Y. Li, Modeling Hardness of Polycrystalline Materials and Bulk Metallic Glasses, Intermetallics, 2011, 19, p 1275–1281. doi:10.1016/j.intermet.2011.03.026

J.E. Zorzi and C.A. Perottoni, Estimating Young’s Modulus and Poisson’s Ratio by Instrumented Indentation Test, Mater. Sci. Eng. A, 2013, 574, p 25–30. doi:10.1016/j.msea.2013.03.008

Acknowledgments

Authors would like to acknowledge CNPq and CAPES for funding this research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Brunetti, C., Pintaude, G. & d’Oliveira, A.S.C.M. The Influence of Fe Content on the Mechanical Properties of NiAl Coatings Processed In-Situ. J. of Materi Eng and Perform 23, 3934–3940 (2014). https://doi.org/10.1007/s11665-014-1203-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1203-5