Abstract

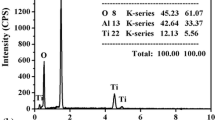

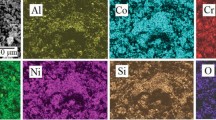

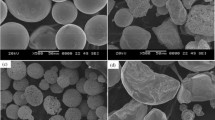

THe present investigation has been conducted to study the tribological properties of Al2O3-13pctTiO2 (AT-13) ceramic coatings deposited on a low carbon steel type E335 by using a thermal flame spray technique. The microstructure and phase composition of wire and coatings were analyzed by scanning electron microscope, energy dispersive spectroscopy (EDS), and X-ray diffraction (XRD). Measurements of micro hardness were also performed on the surface of the coatings. The tribological tests were carried out using a pin-on-disk tribometer at different loads. All tests were performed using two disks as counter body, namely Al2O3-ZrO2 (AZ-25) and Al2O3-TiO2 (AT-3) which formed couple 1 and couple 2, respectively, in order to work out the wear rate and friction coefficient. Roughness profiles were also evaluated before and after each test. The SEM showed that the dense microstructure of Al2O3-TiO2 (AT-13) coatings have a homogenous lamellar morphology and complex of several phases with the presence of porosities and unmelted particles. The XRD analysis of the wire before the spray showed a majority phase of α-Al2O3 rhombohedral structure and a secondary phase of Al2TiO5 orthorhombic structure with little traces of TiO2 (rutile) tetragonal structure, whereas the XRD of the coating revealed the disappearance of TiO2 replaced by the formation of a new metastable phase γ-Al2O3 cubic structure. The tribological results showed that the applied contact pressure affects the variation of the friction coefficient with time and that it decreases with the rise of the normal force of contact. It was found also that the couple 2 with nearly chemical compositions of spray-coated (AT-13) and disk (AT-3) exhibited much higher wear resistance than the couple 1 although they have sliding coefficient of friction nearly.

Similar content being viewed by others

References

S. Brossard, P.R. Munroe, A.T.T. Tran and M.M. Hyland: Surf. Coat. Technol., 2010, vol. 204 (16–17), pp. 2647–56.

L. Wang, Y. Wang, X.G. Sun, J.Q. He, Z.Y. Pan, Y. Zhou and P.L .Wu: Mater. Des, 2011, vol. 32 (1), pp. 36–47.

K. Alamara, S.S. Samandari, P.R. Stoddart and C.C. Berndt: Surf. Coat. Technol., 2011, vol. 206 (6), pp. 1180–87.

M. Wang and L.S. Leon: Surf. Coat. Technol., 2007, vol. 202 (1), pp. 34–44.

A. Keyvani: J. Alloys.Compd., 2015, vol. 623, pp. 229–37.

M. Vicent, E. Bannier, P. Carpio, E. Rayón, R. Benavente, M.D. Salvador, and E. Sánchez: Surf. Coat. Technol., 2015, vol. 268, pp. 209–15.

A. Rico, J. Rodriguez, E. Otero, P. Zeng and W.M. Rainforth: Wear, 2009, vol. 267 (5-8), pp. 1191–97.

Y. Yang, Y. Wang, W. Tian, D.R. Yan, J.-X. Zhang and L. Wang: Mater. Des., 2015, vol. 65, pp. 814–22.

R.S. Lima, B.R. Marple, K.A. Khor, H. Li and P. Cheang: Mater. Sci. Eng. A, 2005, vol. 396 (1-2), pp. 181-187.

V. P. Singh, A. Sil, R. Jayaganthan: Mater. Des., 2011, vol. 32 (2), pp. 584-591.

V. Bolleddu, V. Racherla and P.P. Bandyopadhyay: Mater. Des., 2014, vol. 59, pp. 252–63.

B. Torres, M.A. Garrido, A. Rico, P. Rodrigo, M. Campo and J. Rams: Wear, 2010, vol. 268 (5-6), pp. 828–36.

M.H. Enayati, F. Karimzadeh, M. Jafari, A. Markazi and A. Tahvilian: Mater. Sci. Eng. A, 2013, 578, pp. 46–53.

S. Devaraj, S. Sankaran and R. Kumar: Acta Metall. Sin., 2013, vol. 26, pp. 761–71.

R.J.K. Wood: Int. J. Refract. Met. Hard. Mater., 2010, vol. 28 (1), pp. 82–94.

M. A. Farrokhzad and T. I. Khan: Oxid. Metal, 2014, vol. 81 (1–2), pp. 267–85.

M. Priest: Tribol. Ser., 2003, vol. 41, pp. 739–48.

S. Nourouzi: Ph.D. Thesis, University of Limoges, French, 2004.

V. Fervel, B. Normand and C. Coddet: Wear, 1999, vol. 230 (1), pp. 70–77.

K. A. Habib, J.J. Saura, C. Ferre, M. S. Damra, E. Gimenez and L. Cabedo: Surf. Coat. Technol., 2006, vol. 201 (3–4), pp. 1436–43.

J. Ahn, B. H. Wang, E. P. Song, S. Lee and N. J. Kim: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 1851–1861.

F. Vargas, H. Ageorges, P. Fournier, P. Fauchais, M.E. López : Surf. Coat. Technol., 2010, vol. 205(4), pp. 1132–36.

A. Gaard, P. Krakhmalev, J. Bergström, J.H. Grytzelius, H.M. Zhang: Wear, 2009, vol. 267 (1-4), pp. 387–93.

M. Wang and L. Shaw: Surf. Coat. Technol., 2007, vol. 202 (1), pp. 34–44.

D. Goberman, Y. H. Sohn, L. Shaw, E. Jordan and M. Gell: Acta Mater., 2002, vol. 50 (5), pp. 1141–52.

R. Yilmaz, A.O. Kurt, A. Demir and Z. Tatli: J. Eur. Ceram. Soc. 2007, vol. 27 (2-3), pp. 1319–23.

C.-W. Kim, J.-H. Choi, H.-J. Kim, D.-W. Lee, C.-Y. Hyun, and S.-M. Nam: Ceram. Inter., 2012, vol. 38 (7), pp. 5621–27.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 9, 2015.

Rights and permissions

About this article

Cite this article

Younes, R., Bradai, M.A., Sadeddine, A. et al. Microstructural and Tribological Properties of Al2O3-13pctTiO2 Thermal Spray Coatings Deposited by Flame Spraying. Metall Mater Trans B 46, 2394–2403 (2015). https://doi.org/10.1007/s11663-015-0412-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-015-0412-0