Abstract

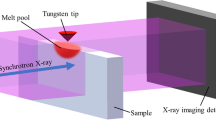

Material flow is a key phenomenon to obtain sound joints by friction stir welding (FSW), and it is highly dependent of the welded material. It is well known that the optimal FSW condition depends on the welded material. However, the material flow during FSW has not been totally clarified in spite of many researches. Especially, the material flow of steel during FSW is still unclear. It seems difficult to understand the material flow by the traditional method such as the tracer method or observation of the microstructure in the stir zone. Therefore, in this study, the material flow of steel was three dimensionally visualized by x-ray radiography using two pairs of x-ray transmission real-time imaging systems, and was then compared with the material flow of aluminum. The result revealed the effect of the welded material on the material flow during FSW.

Similar content being viewed by others

References

W.M. Thomas, E.D. Nicholas, J.C. Needham, M.G. Murch, P. Temple-Smith, C.J. Dawes, International Patent Application No. PCT/GB92/02203, 1991

C.J. Dawes and W.M. Thomas, Friction Stir Process Welds Aluminum Alloys, Weld. J., 1996, 75, p 41–47

S.H.C. Park, Y.S. Sato, and H. Kokawa, Effect of Micro-texture on Fracture Location in Friction Stir Weld of Mg Alloy AZ61 During Tensile Test, Scripta Mater., 2003, 49, p 161–166

H.J. Liu, H. Fujii, M. Maeda et al., Tensile Properties and Fracture Locations of Friction Stir Welded Joints of 2017-T351 Aluminum Alloy, J. Mater. Process. Technol., 2003, 142, p 692–696

K.E. Knipstron and B. Pekkari, Friction Stir Welding Process Goes Commercial, Weld. J., 1997, 76, p 55–63

A. Heidarzadeha, H. Khodaverdizadeha, A. Mahmoudia et al., Tensile Behavior of Friction Stir Welded AA 6061-T4 Aluminum Alloy Joints, Mater. Des., 2012, 37, p 166–173

G. Liu, L.E. Murr, C.-S. Niou et al., Microstructural Aspects of the Friction-Stir Welding of 6061-T6 Aluminum, Scripta Mater., 1997, 37, p 355–361

G. Çam and S. Mıstıkoğlu, Recent Developments in Friction Stir Welding of Al-Alloys, J. Mater. Eng. Perform., 2014, 23, p 1936–1953

G. Çam, Friction Stir Welded Structural Materials: Beyond Al-Alloys, Int. Mater. Rev., 2011, 56, p 1–48

A.P. Reynolds, W. Tang, T. Gnaupel-Herold et al., Structure, Properties, Residual Stress of 304L Stainless Steel Friction Stir Welds, Scripta Mater., 2003, 48, p 1289–1294

S.H.C. Park, Y.S. Sato, H. Kokawa et al., Rapid Formation of the Sigma Phase in 304 Stainless Steel During Friction Stir Welding, Scripta Mater., 2003, 49, p 1175–1180

R. Ueji, H. Fujii, L. Cui et al., Friction Stir Welding of Ultrafine Grained Plain Low-Carbon Steel Formed by the Martensite Process, Mater. Sci. Eng. A, 2006, 423, p 324–330

H. Fujii, L. Cui, N. Tsuji et al., Friction Stir Welding of Carbon Steel, Mater. Sci. Eng. A, 2006, 429, p 50–57

Y. Morisada, H. Fujii, T. Mizuno et al., Nanostructured tool Steel Fabricated by Combination of Laser Melting and Friction Stir Processing, Mater. Sci. Eng. A, 2009, 505, p 157–162

Y. Morisada, H. Fujii, T. Mizuno et al., Modification of Nitride Layer on Cold-Work Tool Steel by Laser Melting and Friction Stir Processing, Surf. Coat. Techol., 2009, 204, p 386–390

W.M. Thomas, P.L. Threadgill, and E.D. Nicholas, Feasibility of Friction Stir Welding Steel, Sci. Technol. Weld. Join., 1999, 4, p 365–372

P.J. Konkol, J.A. Mathars, R. Johnson et al., Friction Stir Welding of HSLA-65 Steel for Shipbuilding, J. Ship Prod., 2003, 19, p 159–164

T.J. Lienert, W.L. Stellwag, B.B. Grimmett et al., Friction Stir Welding Studies on Mild Steel, Weld. J., 2003, 82, p 1s–9s

S.H.C. Park, Y.S. Sato, H. Kokawa et al., Rapid Formation of the Sigma Phase in 304 Stainless Steel During Friction Stir Welding, Scripta Mater., 2003, 49, p 1175–1180

K. Colligan, Material Flow Behavior During Friction Stir Welding of Aluminum, Weld. Res., 1999, 78, p 229–237

M. Guerra, C. Schmidta, J.C. McClurea et al., Flow Patterns During Friction Stir Welding, Mater. Charact., 2003, 49, p 95–101

Y. Li, L.E. Murr, and J.C. McClure, Flow Visualization and Residual Microstructures Associated with the Friction-Stir Welding of 2024 Aluminum to 6061 Aluminum, Mater. Sci. Eng. A, 1999, 271, p 213–219

P. Su, A. Gerlich, T.H. North et al., Intermixing in Dissimilar Friction Stir Spot Welds, Metall. Mater. Trans. A, 2007, 38A, p 584–595

B.C. Liechty and B.W. Webb, The Use of Plasticine as an Analog to Explore Material Flow in Friction Stir Welding, J. Mater. Process. Technol., 2007, 184, p 240–250

G. Buffa, J. Huaa, R. Shivpuri et al., Design of the Friction Stir Welding Tool Using the Continuum Based FEM Model, Mater. Sci. Eng. A, 2006, 419, p 381–388

Y. Shimoda, M. Tsubai, T. Yasui et al., Experimental and Numerical Studies of Material Flow During Welding by Friction Stirring, J. Jpn. Weld. Soc., 2011, 29, p 114–118

H. Pashazadeh, J. Teimournezhad, and A. Masoumi, Numerical investigation on the Mechanical, Thermal, Metallurgical and Material Flow Characteristics in Friction Stir Welding of Copper Sheets with Experimental Verification, Mater. Des., 2014, 55, p 619–632

G.Q. Chen, Q.Y. Shi, Y. Fujiya et al., Simulation of Metal Flow During Friction Stir Welding Based on the Model of Interactive Force Between Tool and Material, J. Mater. Eng. Perform., 2014, 23, p 1321–1328

Y. Morisada, H. Fujii, Y. Kawahito et al., Three-Dimensional Visualization of Material Flow During Friction Stir Welding by Two Pairs of X-ray Transmission Systems, Scripta Mater., 2011, 65, p 1085–1088

Y. Morisada, H. Fujii, T. Nagaoka et al., Fullerene/A5083 Composites Fabricated by Material Flow During Friction Stir Processing, Composites A, 2007, 38, p 2097–2101

Y. Morisada, T. Imaizumi, and H. Fujii, Clarification of Defect Formation Mechanism in Friction Stir Welding by X-ray Radiography, J. Jpn. Weld. Soc., 2014, 32, p 31–37

Acknowledgments

The authors wish to acknowledge the financial support of a Collaborative Research Based on Industrial Demand “Heterogeneous Structure Control: Towards Innovative Development of Metallic Structural Materials” by Japan Science and Technology Agency (JST), the Global COE Programs and Grant-in-Aid from the Ministry of Education, Culture, Sports, Science and Technology (MEXT), Japan, and ISIJ Research Promotion Grant.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Morisada, Y., Imaizumi, T., Fujii, H. et al. Three-Dimensional Visualization of Material Flow During Friction Stir Welding of Steel and Aluminum. J. of Materi Eng and Perform 23, 4143–4147 (2014). https://doi.org/10.1007/s11665-014-1202-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1202-6