Abstract

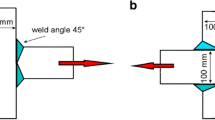

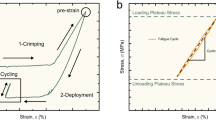

Zero mean strain rotating beam fatigue testing has become the standard for comparing the fatigue properties of Nitinol wire. Most commercially available equipment consists of either a two-chuck or a chuck and bushing system, where the wire length and center-to-center axis distance determine the maximum strain on the wire. For the two-chuck system, the samples are constrained at either end of the wire, and both chucks are driven at the same speed. For the chuck and bushing system, the sample is constrained at one end in a chuck and rides freely in a bushing at the other end. These equivalent systems will both be herein referred to as Chuck-to-Chuck systems. An alternate system uses a machined test block with a specific radius to guide the wire at a known strain during testing. In either system, the test parts can be immersed in a temperature-controlled fluid bath to eliminate any heating effect created in the specimen due to dissipative processes during cyclic loading (cyclic stress induced the formation of martensite) Wagner et al. (Mater. Sci. Eng. A, 378, p 105–109, 1). This study will compare the results of the same starting material tested with each system to determine if the test system differences affect the final results. The advantages and disadvantages of each system will be highlighted and compared. The factors compared will include ease of setup, operator skill level required, consistency of strain measurement, equipment test limits, and data recovery and analysis. Also, the effect of test speed on the test results for each system will be investigated.

Similar content being viewed by others

References

A. Pelton, J. DiCello, S. Miyazaki, “Optimization of Processing and Properties of Medical-Grade Nitinol Wire”, SMST-2000 Proceedings of the International Conference on Shape Memory and Superelastic Technologies, S.M. Russel and Alan R. Pelton, Eds., Pacific Grove, International Organization on SMST, California, 2001, p 361–374

D. Norwich and A. Fasching, “A Study on the Effect of Diameter on the Fatigue Properties of NiTi Wire”, SMST-2008 Proceedings of the International Conference on Shape Memory and Superelastic Technologies, A. Tuissi, M. Mitchell and J. San Juan, Eds., Stresa, Italy, 2009, p 558–562

P.C. Clarke and A.C. Bates, Hunter Spring Company ca. 1940

B. Reedlunn, C. Churchill, E. Nelson, J. Shaw, and S. Daly, Tension, Compression, and Bending of Superelastic Shape Memory Tubes, J. Mech. Phys. Solids, 2014, 63, p 506–537

M. Polinsky, D. Norwich, and M. Wu, “A Study on the Effects of Surface Modifications and Processing on the Fatigue Properties of NiTi Wire”, SMST-2006 Proceedings of the International Conference on Shape Memory and Superelastic Technologies, B. Berg, M. Mitchell, and J. Proft, Eds., Pacific Grove, CA, 2008 p 1–17

M. Wagner, T. Sawaguchi, G. Kaustrater, D. Hoffken, and G. Eggeler, Structural Fatigue of Pseudoelastic NiTi Shape Memory Wires, Mater. Sci. Eng. A, 2004, 378, p 105–109

Z. Lin, K. Pike, M. Schlun, A. Zipse, and J. Draper, “Nitinol Fatigue Life for Variable Strain Amplitude Fatigue”, SMST-2011 Proceedings of the International Conference on Shape Memory and Superelastic Technologies, M. Mitchell, Ed., Hong Kong, China, 2012 p 2628–2632

Acknowledgements

I would like to thank Karen Duran and Dale Mandanici of Memry Corporation for their tireless efforts in testing countless iterations of samples for this and many other research studies. Their assistance with the ever changing requests of the author is greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the International Conference on Shape Memory and Superelastic Technologies 2013, held in May 20-24, 2013, in Prague, Czech Republic, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Norwich, D.W. A Comparison of Zero Mean Strain Rotating Beam Fatigue Test Methods for Nitinol Wire. J. of Materi Eng and Perform 23, 2515–2522 (2014). https://doi.org/10.1007/s11665-014-0939-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-0939-2