Abstract

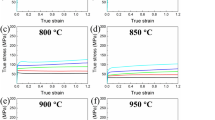

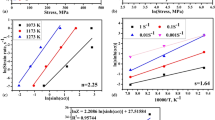

For predicting the high-temperature deformation behavior in a Cu-0.4 Mg alloy, the true stress-strain data from isothermal hot compression tests on a Gleeble-1500 thermo-mechanical simulator, in a wide range of temperatures (500, 600, 700, 750, and 800 °C) and strain rates (0.005, 0.01, 0.1, 1, 5, and 10 s−1), were employed to develop the Arrhenius-type constitutive model and the artificial neural network (ANN) constitutive model. Furthermore, prediction ability of the two models for high-temperature deformation behavior was evaluated. Correlation coefficients (R) between the experimental and predicted flow stress for the Arrhenius-type constitutive model and the ANN constitutive model are 0.9860 and 0.9998, respectively, and average absolute relative errors between the experimental and predicted flow stress for these two models are 5.3967% and 0.7401%, respectively. Results show that the ANN constitutive model can accurately predict the high-temperature deformation behavior over a wider range of temperatures and strain rates, while for the Arrhenius-type constitutive model there is greater divergence in the regime of high strain rates and low temperatures.

Similar content being viewed by others

References

Y.C. Lin and Xiao-Min Chen, A Critical Review of Experimental Results and Constitutive Descriptions for Metals and Alloys in Hot Working, Mater. Des., 2011, 32, p 1733–1759

C. Sellars and W.M. Tegart, On the Mechanism of Hot Deformation, Acta Metall., 1966, 14, p 1136–1138

H.J. McQueen and N.D. Ryan, Constitutive Analysis in Hot Working, Mater. Sci. Eng. A, 2002, 322, p 43–63

F.A. Slooff, J. Zhou, J. Duszczyk, and L. Katgerman, Constitutive Analysis of Wrought Magnesium Alloy Mg-Al4-Zn1, Scripta Mater., 2007, 57, p 759–762

Y.C. Lin, Ming-Song Chen, and Jue Zhong, Constitutive Modeling for Elevated Temperature Flow Behavior of 42CrMo Steel, Comput. Mater. Sci., 2008, 42, p 470–477

S. Mandal, V. Rakesh, P.V. Sivaprasad, and S. Venugopal, Constitutive Equations to Predict High Temperature Flow Stress in a Ti-modified Austenitic Stainless Steel, Mater. Sci. Eng. A, 2009, 500, p 114–121

Sumantra Mandal, P.V. Sivaprasad, S. Venugopal, and K.P.N. Murthy, Constitutive Flow Behavior of Austenitic Stainless Steels Under Hot Deformation: Artificial Neural Network Modelling to Understand, Evaluate and Predict, Model. Simul. Mater. Sci. Eng., 2006, 14, p 1053–1070

Guoliang Ji, Fuguo Li, Qinghua Li, Huiqu Li, and Zhi Li, Prediction of the Hot Deformation Behavior for Aermet100 Steel Using an Artificial Neural Network, Comput. Mater. Sci., 2010, 48, p 626–632

Sumantra Mandal, P.V. Sivaprasad, and S. Venugopal, Capability of a Feed-Forward Artificial Neural Network to Predict the Constitutive Flow Behavior of as Cast 304 Stainless Steel Under Hot Deformation, J. Eng. Mater. Technol., 2007, 129, p 242–247

A. Jenab, A. Karimi Taheri, and K. Jenab, The Use of Ann to Predict the Hot Deformation Behavior of AA7075 at Low Strain Rates, J. Mater. Eng. Perform., 2013, 22, p 903–910

G. Ji, F. Li, Q. Li, H. Li, and Z. Li, A Comparative Study on Arrhenius-type Constitutive Model and Artificial Neural Network Model to Predict High-temperature Deformation Behaviour in Aermet100 Steel, Mater. Sci. Eng. A, 2011, 528, p 4774–4782

P. Wu, S. Xie, and G. Huang, Materials and Process Technics of Copper Contact Wires for High-speed Train, Chin. J Rare Met., 2006, 30, p 203–208

X.G. Fan, H. Yang, Z.C. Sun, and D.W. Zhang, Quantitative Analysis of Dynamic Recrystallization Behavior Using a Grain Boundary Evolution Based Kinetic Model, Mater. Sci. Eng. A, 2010, 527, p 5368–5377

C. Zener and H. Hollomon, Effect of Strain Rate upon Plastic Flow of Steel, J. Appl. Phys., 1944, 15, p 22–32

J. Jonas and C.M. Sellars, Strength and Structure Under Hot-working Conditions, Int. Metal. Rev., 1969, 14(1), p 1–24

Acknowledgment

The authors would appreciate the financial support received from Materials Processing Engineering Development Funds of Henan Polytechnic University and from the Science and Technology Research Funds of the Education Department of Henan Province (12A430008).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ji, G., Yang, G., Li, L. et al. Modeling Constitutive Relationship of Cu-0.4 Mg Alloy During Hot Deformation. J. of Materi Eng and Perform 23, 1770–1779 (2014). https://doi.org/10.1007/s11665-014-0912-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-0912-0