Abstract

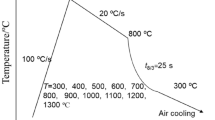

The effects of initial grain size and strain on the static recrystallized grain size of coarse-grained austenite in an API-X70 steel microalloyed with Nb, V, and Ti were investigated using a Gleeble-3800 thermomechanical simulator. The results indicate that the static recrystallized grain size of coarse-grained austenite decreases with decreasing initial grain size and increasing applied strain. The addition of microalloying elements can lead to a smaller initial grain size for hot deformation due to the grain growth inhibition during reheating, resulting in decreasing of static recrystallized grain size. Based on the experimental data, an equation for the static recrystallized grain size was derived using the least square method. The grain sizes calculated using this equation fit well with the measured ones compared with the equations for fine-grained austenite and for coarse-grained austenite of Nb-V microalloyed steel.

Similar content being viewed by others

References

E. Valdes and C.M. Sellars, Influence of Roughing Rolling Passes on Kinetics of Strain Induced Precipitation of Nb(C,N), Mater. Sci. Technol., 1991, 7(7), p 622–630

A.P. Singh, D. Sengupta, S. Jha, M.P. Yallasira, and N.S. Mishra, Predicting Microstructural Evolution and Yield Strength of Microalloyed Hot Rolled Steel Plate, Mater. Sci. Technol., 2004, 20(10), p 1317–1325

J.H. Beynon and C.M. Sellars, Modelling Microstructure and Its Effects During Multipass Hot Rolling, ISIJ Int., 1992, 32, p 359–367

A. Sandberg and R. Sandstrom, Recrystallization of Molybdenum and Nitrogen Alloyed Austenitic Stainless Steels After Hot Working, Mater. Sci. Technol., 1986, 2(9), p 917–925

C.M. Sellars, The Physical Metallurgy of Hot working, Proc. Int. Conf. Hot Working and Forming Processes, C.M. Sellars and G.J. Davies, Ed., The Metal Society, London, 1980, pp. 3–15

D.Q. Bai, S. Yue, W.P. Sun, and J.J. Jonas, Effect of Deformation Parameters on the No-Recrystallization Temperature in Nb-Bearing Steels, Metall. Mater Trans. A, 1993, 24A, p 2151–2159

F. Siciliano, Jr, and J.J. Jonas, Mathematical Modeling of the Hot Strip Rolling of Microalloyed Nb, Multiply-Alloyed Cr-Mo, and Plain C-Mn Steels, Metall. Mater. Transl., 2000, 31A(2), p 511–530

X. Liu, J.K. Solberg, R. Gjengedal, and A.O. Kluken, Modelling of Interaction Between Recrystallisation and Precipitation during Multipass Rolling of Niobium Microalloyed Steel, Mater. Sci. Technol., 1995, 11(5), p 469–473

P. Uranga, A.I. Fernandez, B. Lopez, and J.M. Rodriguez-Ibabe, Modeling of Austenite Grain Size Distribution in Nb Microalloyed Steels Processed by Thin Slab Casting and Direct Rolling (TSDR) Route, ISIJ Int., 2004, 44(8), p 1416–1425

R. Abad, A.I. Fernandez, B. Lopez, and J.M. Rodriguez-Ibabe, Interaction between Recrystallization and Precipitation during Multipass Rolling in a Low Carbon Niobium Microalloyed Steel, ISIJ Int., 2001, 41, p 1373–1382

Q.Y. Sha and Z.Q. Sun, Prediction of Grain Growth of Coarse-Grained Austenite in Nb-V-Ti Microalloyed Steel, Mater Sci Technol., 2011, 27, p 1408–1411

Q.Y. Sha and Z.Q. Sun, Grain Growth Behavior of Coarse-Grained Austenite in a Nb-V-Ti Microalloyed Steel, Mater. Sci. Eng. A, 2009, 523A, p 77–84

ASTM, Standard Test Methods for Determining Average Grain Size. ASTM Designation E112, pp. 267–292

Q.Y. Sha and Z.Q. Sun, Microstructure and Precipitation in As Cast Low Carbon Nb-V-Ti Microalloyed Medium Thin Slab, Ironmak. Steelmak., 2010, 37, p 320–325

W.P. Sun and E.B. Hawbolt, Comparison Between Static and Metadynamic Recrystallization—An Application to the Hot Rolling of Steels, ISIJ Int., 1997, 37, p 1000–1009

Q.Y. Sha, L.F. Qiao, R.J. Xu, G.J. Huang, and Z.Q. Sun, Comparison of Grain Growth Between Fine-Grained and Coarse-Grained Austenite in a Nb-V-Ti Microalloyed Steel, Mater. Sci. Forum, 2010, 638-642, p 3496–3501

B. Mirzakhani, M.T. Salehi, S. Khoddam, S.H. Seyedein, and M.R. Aboutalebi, Investigation of Dynamic and Static Recrystallization Behavior during Thermomechanical Processing in a API-X70 Microalloyed Steel, J. Mater. Eng. Perform., 2009, 18, p 1029–1034

L.J. Cuddy and J.C. Raley, Austenite Grain Coarsening in Microlloyed Steel, Metall. Mater. Trans., 1983, 14, p 1989–1995

A.J. DeArdo, Morden Thermomechanical Processing of Microalloyed Steel: A Physical Metallurgy Perspective, Proc. Int. Conf. Microalloy’95. Iron and Steel Society, Inc., Pittsburgh, 1995, p. 15–33

J. Majta, J.G. Lenard, and M. Pietrzyk, Modelling the Evolution of the Microstructure of a Nb Steel, ISIJ Int., 1996, 36, p 1094–1102

Acknowledgments

The authors would like to thank Professor Zuqing Sun and Professor Longfei Li for helpful discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sha, Q., Li, G. & Li, D. Static Recrystallized Grain Size of Coarse-Grained Austenite in an API-X70 Pipeline Steel. J. of Materi Eng and Perform 22, 3626–3630 (2013). https://doi.org/10.1007/s11665-013-0688-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0688-7