Abstract

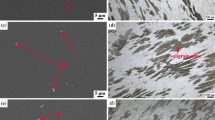

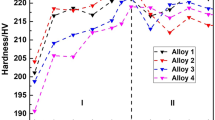

This paper investigates the influence of Cu contents on the precipitated phases and the resultant properties of Al-Zn-Mg-Cu alloys. The quantities of three major precipitated phases and phase diagrams of Al-Zn-Mg-Cu alloys with various Cu contents have been calculated based on materials models and properties database. The results show that the amount of the main hardening η (MgZn2) phase increases with an increase in Cu content up to 1.4% (wt.%), whereby the maximum amount of η phase can be obtained. S (Al2CuMg) phase forms markedly as Cu content increases and the precipitation process occurs rapidly at early stage with temperature between 430 and 480 °C. T (A12Mg3Zn3) phase reduces significantly as the Cu content increases, and the presence of T phase in the alloy largely depends on the Cu:Mg ratio. The experimental verification for the presence of major phases is in good accordance with the modeling results. The physical and mechanical properties of the alloys under various heat treatment conditions have also been simulated.

Similar content being viewed by others

References

P. Sepehrband and S. Esmaeili, Application of Recently Developed Approaches to Microstructural Characterization and Yield Strength Modeling of Aluminum Alloy AA7030, Mater. Sci. Eng. A, 2008, 487, p 309–315

T. Marlaud, A. Deschamps, F. Bley, W. Lefebvre, and B. Baroux, Evolution of Precipitate Microstructures During the Retrogression and Re-Ageing Heat Treatment of an Al-Zn-Mg-Cu Alloy, Acta Mater., 2010, 58, p 248–260

M.A. Suarez, O. Alvarez, M.A. Alvarez, R.A. Rodriguez, S. Valdez, and J.A. Juarez, Characterization of Microstructures Obtained in Wedge Shaped Al-Zn-Mg Ingots, J. Alloys Compd., 2010, 492, p 373–377

X.M. Li and M.J. Starink, DSC Analysis of Phase Transitions and Their Correlation with Properties of Overaged Al-Zn-Mg-Cu Alloys, J. Mater. Eng. Perform., 2012, 21, p 977–984

X.M. Li and M.J. Starink, The Effect of Compositional Variations on Characteristics of Coarse Intermetallic Particles in Overaged 7000 Aluminium Alloys, Mater. Sci. Technol., 2001, 171, p 324–1328

J.K. Park and A.J. Ardell, Precipitate Microstructure of Peak-Aged 7075 Al, Scr. Metall., 1988, 22, p 1115–1119

J.T. Burns, J.M. Larsen, and R.P. Gangloff, Driving Forces for Localized Corrosion-to-Fatigue Crack Transition in Al-Zn-Mg-Cu, Fatigue Fract. Eng. Mater. Struct., 2011, 34, p 745–773

N. Yazdian, F. Karimzadeh, and M. Tavoosi, Microstructural Evolution of Nanostructure 7075 Aluminum Alloy During Isothermal Annealing, J. Alloys Compd., 2010, 493, p 137–141

M.J. Starink and X.M. Li, A Model for the Electrical Conductivity of Peak Aged and Overaged Al-Zn-Mg-Cu Alloys, Metall. Mater. Trans. A, 2003, 34A, p 899–911

Z. Guo, N. Saunders, A.P. Miodownik, and J.-Ph. Schillé, Modeling of Materials Properties and Behaviour Critical to Casting Simulation, Mater. Sci. Eng. A, 2005, 413-414, p 465–469

X. Li and S. Soo, Numerical Simulation of the Superplastic Forming of a Dental Ridge Augmentation Membrane, Mater. Manuf. Process., 2010, 25, p 1470–1476

J. Yu and X. Li, Modeling of the Precipitated Phases and Properties of Al-Zn-Mg-Cu Alloys, J. Phase Equilib. Diffus., 2011, 32, p 350–360

Z. Guo, N. Saunders, J.P. Schillé, and A.P. Miodownik, Material Properties for Process Simulation, Mater. Sci. Eng. A, 2009, 499, p 7–13

X. M. Li, and Y. Ding, Modeling Analysis and Experimental Studies of Pure Iron Processed by Asymmetric Rolling, The 5th International Conference on Nanomaterials by Severe Plastic Deformation, March 2011 (Nanjing, China), Mater Sci Forum, 2011, 667-669, p 139–144

N. Saunders, Z. Guo, X. Li, A.P. Miodownik, and J.-Ph. Schillé, Using JMatPro to Model Materials Properties and Behaviour, JOM, 2003, 55, p 60–65

G. Zhong, S. Wu, H. Jiang, and P. An, Effects of Ultrasonic Vibration on the Iron-Containing Intermetallic Compounds Of High Silicon Aluminum Alloy with 2% Fe, J. Alloys Compd., 2010, 492, p 482–487

N. Kamp, A. Sullivan, and J.D. Robson, Modeling of Friction Stir Welding of 7xxx Aluminium Alloys, Mater. Sci. Eng. A, 2007, 466, p 246–255

X. Cao, N. Saunders, and J. Campbell, Effect of Iron and Manganese Contents on Convection-Free Precipitation and Sedimentation of Primary α-Al(FeMn)Si Phase in Liquid Al-11.5Si-0.4Mg Alloy, J. Mater. Sci., 2004, 39, p 2303–2314

H.M. Flower, High Performance Materials in Aerospace, Chapman & Hall, London, UK, 1995

H.R. Shercliff and M.F. Ashby, A Process Model for Age Hardening of Aluminium Alloys-I. The Model, Acta Metall. Mater., 1990, 38, p 1789–1802

R.W. Cahn, P. Haasen, and E.J. Kramer, Materials Science and Technology-Structure and Properties of Nonferrous Alloys, VCH Publishers Inc., New York, USA, 1996

A. Deschamps, F. Livet, and Y. Brechet, Influence of Predeformation on Ageing in an Al-Zn-Mg Alloy-I. Microstructure Evolution and Mechanical Properties, Acta Mater., 1998, 47, p 281–292

X.M. Li and M.J. Starink, Identification and Analysis of Intermetallic Phases in Overaged Zr-Containing and Cr-Containing Al-Zn-Mg-Cu Alloys, J. Alloys Compd., 2011, 509, p 471–476

D.J. Strawbridge, W. Hume-Rothery, and A.T. Little, The Constitution of Al-Cu-Mg-Zn Alloys at 460 °C, J. Inst. Met., 1948, 74, p 191–225

I.J. Polmear, Light Alloys-Metallurgy of the Light Metals, St. Edmundsbury Press Ltd, Suffolk, UK, 1996

M. Dhiman, D.K. Dwivedi, R. Sehgal, and I.K. Bhat, Effect of Iron on Microstructure of Al-12Si-1Cu-0.1Mg Alloy, Mater. Manuf. Process., 2008, 23, p 805–808

Z. Guo and W. Sha, Quantification of Precipitate Fraction in Al-Si-Cu Alloys, Mater. Sci. Eng. A, 2005, 392, p 449–452

T.C. Tsai and T.H. Chuang, Atmospheric Corrosion Cracking of a Superplastic 7475 Aluminum Alloy, Metall. Mater. Trans. A, 1996, 27A, p 2617–2627

K.S. Ghosh, K. Das, and U.K. Chatterjee, Correlation of Stress Corrosion Cracking Behaviour with Electrical Conductivity and Open Circuit Potential in Al-Li-Cu-Mg-Zr Alloys, Mater. Corros., 2007, 58, p 181–188

R.R. Sawtell and J.T. Staley, Interactions Between Quenching and Aging in Alloy 7075, Aluminium, 1983, 59, p 127–133

T.C. Tsai and T.H. Chuang, Relationship Between Electrical Conductivity and Stress Corrosion Cracking Susceptibility of Al 7075 and Al 7475 Alloys, Corrosion, 1996, 6, p 414–416

J.K. Park and A.J. Ardell, Relationship Between Electrical Conductivity and Stress Corrosion Cracking Susceptibility of Al 7075 and Al 7475 Alloys, Acta Metall. Mater., 1991, 39, p 591–598

P. Olafsson, R. Sandstrom, and A. Karlsson, Electrical Conductivity of Aluminium Alloys, Mater. Sci. Forum, 1996, 217-222, p 981–986

Y. Zeng, S. Mu, P. Wu, K.P. Ong, and J. Zhang, Relative Effects of all Chemical Elements on the Electrical Conductivity of Metal and Alloys: An Alternative to Norbury-Linde Rule, J. Alloys Compd., 2009, 478, p 345–354

T.S. Huang and G.S. Frankel, Kinetics of Sharp Intergranular Corrosion Fissures in AA7178, Corros. Sci., 2007, 49, p 858–876

J. Guo and M.T. Samonds, Alloy Thermal Physical Property Prediction Coupled Computational Thermodynamics with Back Diffusion Consideration, J. Phase Equilib. Diffus., 2007, 28, p 58–63

J.M. Molina, R. Prieto, J. Narcisoa, and E. Louis, The Effect of Porosity on the Thermal Conductivity of Al-12 wt.% Si/SiC Composites, Scr. Mater., 2009, 60, p 582–585

L.F. Mondolfo, Aluminium Alloys: Structure and Properties, Butterworth & Co Ltd, England, 1976

T.J. Warner, R.A. Shahani, P. Lassince, and G.M. Raynaud, Improved Durability Aluminium Alloys for Airframe Structures, 3rd ASM Conf. on Synthesis, Processing and Modeling of Advanced Materials, 1997, Paris, France

Acknowledgments

The Key Laboratory for Advanced Metallic Materials of Jiangsu Province, Southeast University, China, is gratefully acknowledged for providing the usage of JMatPro 6 software. The authors would like to thank Mr. Y. J. Chen for valuable technical discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, X., Yu, J.J. Modeling the Effects of Cu Variations on the Precipitated Phases and Properties of Al-Zn-Mg-Cu Alloys. J. of Materi Eng and Perform 22, 2970–2981 (2013). https://doi.org/10.1007/s11665-013-0588-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0588-x