Abstract

This research studies the effects of titanium added in an amount up to 0.13 wt.% on the microstructure and mechanical properties. The research was conducted for thin-walled iron castings with 3-5 mm wall thickness and for the reference casting with 13 mm wall thickness to achieve various cooling rates. Microstructural changes were evaluated by analyzing quantitative data sets obtained by image analyzer and also using scanning electron microscope. Metallographic examination revealed in thin-walled castings a significant effect of the addition of Ti to compacted graphite, much stronger in comparison with castings with thicker sections. Moreover, thin-walled castings with high degrees of inoculation and which have been solidified under high cooling rates have a homogeneous structure, free of chills, and good mechanical properties, which may predispose them for potential use as substitutes for aluminum alloy castings in diverse applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Compacted graphite iron (CGI) also known as the vermicular graphite cast iron is an alloy with attractive features that is used in the automotive industry (Ref 1-4) for brake discs and brake drums, exhaust manifolds, engine heads, and diesel engine blocks, and is traditionally manufactured from gray cast iron. CGI allows the manufacture of diesel engines with better combustion and performance. CGI may be used for light castings with good mechanical properties and performance, with especially good vibration damping capacity, good thermal conductivity (Ref 5, 6), higher pressures, and is relatively low production cost (Ref 7). From the point of view of economics and ecology, thin-walled castings of CGI can compete in terms of mechanical properties with the “light” aluminum alloy castings.

The main factors that influence the structure of CGI castings are chemical composition, cooling rate, liquid treatment, and heat treatment (Ref 8, 9). The cooling rate of a casting is primarily a function of its section size, pouring temperature, and the ability of the material mold to absorb heat. The process of obtaining thin-walled castings is not simple, because it is associated with a wide range of cooling rates at the beginning of graphite eutectic solidification (Ref 10). With increasing cooling rates in thin-walled CGI castings, thermal undercooling increases and graphite gradually becomes nodular, resulting in an increased nodule count and lower compact graphite ratio. Therefore, the production of thin-walled compacted iron castings is more difficult than that of thicker section iron (Ref 11).

The formation of CGI is a very difficult process to control with only a narrow margin of residual Mg: too much Mg will give an excess of nodules, whereas too little Mg will lead to the formation of gray iron flake structures (Ref 12). From the literature (Ref 7), it follows that even at magnesium levels as low as 0.01% it is not possible to obtain acceptable CGI with wall thicknesses of 4 mm due to excessive graphite nodularity. The treatment of iron with addition of antispheroidizing elements (Al, Bi, Ti, Zr, Sb) has much wider industrial application. The use of Ti as a key alloying elements has advantages and disadvantages. Magnesium-titanium combination helps to extend the working range of magnesium to achieve successful production of CGI castings (Ref 8, 9). A major concern with regard to titanium additions is contamination of casting returns and reduced machinability (Ref 1). Foundry practice and good production discipline could not be sufficient to maintain the consistency of the desired microstructure without the use of antispheroidizing elements such as titanium. The literature provides limited data (Ref 1, 7, 13) on the influence of Ti addition on high cooling rate-structure relations of CGI, which is a crucial property in the formation of thin-walled castings. This article presents an analysis of the addition of Ti on the microstructure and mechanical properties of thin-walled castings with different wall thicknesses.

Experimental

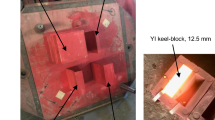

The experimental melts were done in an electric induction furnace of intermediate frequency in a 15 kg capacity crucible. The furnace charge consisted of the following materials: Sorelmetal, technically pure silicon, Fe-Mn, Fe-S, and steel scrap. After metal heating to a temperature of 1490 °C, the bath was held for 2 min and then, vermicularization and inoculation operations were performed by a bell method. For the vermicularization, the foundry alloy Fe-Si-Mg (6% Mg) as well as Fe-Ti in an amount given in Table 1 were used, while the inoculation was done by means of the Fe-Si alloy (75% Si, 0.75-1.25% Ca, 0.75-1.25% Ba, 0.75-1.25% Al) inoculant in an amount of 0.6 wt.%. The pouring temperature was 1400 °C. In this experiment, CGI plate castings with section sizes of 3, 5, and 13 mm were produced. The sand mold was prepared using conventional green molding sand made of silica sand, bentonite (7 wt.%), water/bentonite ratio amounts to 0.4%, and a granularity of 100-200 μm. In addition, they were instrumented with Pt/PtRh10 thermocouples in a diameter of 0.1 mm entering a two-hole Al2O3 tube. The thermocouple tips were located in the geometrical center of each mold cavity normal to the heat transfer flow to improve the measurement accuracy. An Agilent 34970A electronic module was employed for numerical temperature recording. Figure 1 shows the examples of cooling curves of the investigated thin-walled iron castings.

Chemical compositions are tabulated in Table 2.

Metallographic characterization was made using a Leica MEF 4M microscope and QWin v3.5 quantitative analyzer at various magnifications to observe graphite morphology and matrix. The analysis was based on the use of a line scan of the measuring area. This method counts the number of graphite nodules which have been cut by the line scan. The final result was the arithmetical average of the graphite nodule fraction in the microstructure during the scan of at least five areas of the central part of the sample. In addition, the fractured surfaces were examined by a JEOL JSM-550LV scanning electron microscope (SEM) operated at 20 kV.

Brinell hardness measurements were made in an HPO-250 hardness tester and tensile testing was performed in a universal Zwick/Roell Z050 following the ASTM E8M standard. Specimen dimensions are shown in Fig. 2.

Experimental Results and Analysis

Analysis of Microstructure

Figures 3 to 5 show the exhibited microstructures found in castings with different wall thicknesses from heats I-IV.

The results of metallographic examination are given in Table 3.

Metallographic examination revealed a significant effect of the addition of Ti to compacted graphite, especially in thin-walled castings. The addition of Ti requires the addition of extra magnesium to stay safely away from the risk of formation of graphite flake structures (see Fig. 3b). Studies show that Ti addition reduces the graphite nodule fraction in cast iron (G = 3 mm) from 73% for the base iron to 34% for cast iron with the addition of 0.13% Ti. It is usual to set a limit of 20% nodularity for CGI specifications (Ref 8, 9, 14). In the case of thin-walled castings, the natural tendency of CGI is to solidify with higher nodularity, which may result in the thin outer walls (<4-5 mm) having up to 50% nodularity (Ref 1). In the case of thin-walled castings with greater wall thickness (G = 5 mm) after the addition of 0.13% Ti the graphite fraction is reduced to below 20%, thus meeting the ASTM standards (Ref 14). According to one study (Ref 13), the addition of 0.15% titanium increases the compacted graphite fraction in castings with a wall thickness of 30-80 mm only by approximately 10%, and has a negligible impact on the mechanical properties. This study shows that the use of 0.13% Ti in thin-walled castings has a much stronger effect on the solidification of compacted graphite in comparison with castings with thicker sections. Analysis of the cast iron matrix shows that the addition of Ti slightly decreases the ferrite fraction in the casting (Table 3). Titanium causes solidification of carbides (TiC) in cast iron. Figure 6 shows crystals of TiC in the cast iron microstructure.

Titanium carbides in the form of faceted crystals are evenly distributed in iron matrix. Metallographic analysis shows that their maximum size is <4 μm, and their fraction is much lower than 1%.

The process of obtaining thin-walled castings is not easy, as it is associated with a high range of cooling rates. This contributes to a greater tendency toward the formation of defects, in particular structural inhomogeneity and the occurrence of chills (Ref 10). Knowledge of the effect of technological factors on the cooling rate and on the physicochemical state of liquid iron is of fundamental importance for the preparation of thin-walled castings with good mechanical properties and performance, and without casting defects. Characteristic features of thin-walled castings are also significant changes of cooling rate during insignificant wall thickness variation. The thermal analysis (Fig. 1) shows that the change in wall thickness from 5 to 3 mm results in a significant increase in the cooling rate from Q = 10.0 °C/s to Q = 26.6 °C/s. This causes shortening of the solidification time from 40 to 18 s and the risk of chill occurrence in cast iron. For this purpose, in thin-walled nodular or CGI castings a high degree of inoculation is required (Ref 15). In the case of CGI, it is particularly disadvantageous in view of the fact that increasing nucleation potential decreases the amount of compacted graphite and increases the graphite nodule fraction. This study shows that the addition of Ti enables, in thin-walled castings with a high degree of inoculation and solidified under high cooling rate, the obtention of a homogeneous structure of cast iron, free of chills, with a high compacted graphite fraction.

Mechanical Properties of Experimental Alloys

The effects of Ti addition and casting size on the mechanical properties of CGI castings are depicted in Fig. 7.

From the results shown in Fig. 7 one can see that no significant increase in the hardness occurs for Ti addition up to 0.13%. It can be seen that the tensile strength slightly increases with the addition of Ti up to 0.09% Ti. Further increasing the titanium causes a decrease in both the tensile strength and the elongation of thin-walled iron castings. This is due to an increase in the compacted graphite fraction in the cast iron microstructure, with a higher length to thickness ratio (Fig. 3d to 5d). In the case of reference casting (G = 13 mm), the addition of Ti does not appreciably affect the R m or HBW, while elongation is lowered to the level of 6.4%.

In conclusion, It can be said that the addition of titanium up to 0.13 wt.% effectively increases the compacted graphite fraction and pearlite percentage, owing to the anti-spheroidising and carbide-forming potential of Ti. Increasing the compacted graphite fraction reduces ductility, while increasing pearlite percentage strengthens the metallic matrix. These contradictory effects resulted in CGI castings with added titanium having relatively unchanged tensile strength and hardness. The structural characteristics, including the absence of chills, uniformly distributed TiC, ferritic-pearlitic matrix, and high fraction of compacted graphite predispose thin-walled CGI castings for potential use as substitutes for aluminum alloy castings in diverse applications.

Conclusions

From this study, the following conclusions can be drawn:

-

1.

From the experiments it is concluded that even at Mg levels as low as 0.01% it is not possible to obtain acceptable fraction of compacted graphite in thin-walled castings (G ≤ 5 mm) because of excessive nodularity. The introduction of Ti in amounts up to 0.13% iron allows a high proportion of compacted (vermicular) graphite in thin-walled castings.

-

2.

A homogeneous structure and free of chills was obtained despite high cooling rates that are typical for thin-walled castings. The addition of Ti results in solidification of Ti carbides in the form of faceted crystals, which are uniformly distributed in the iron matrix. Their maximum size is <4 μm, and their volume fraction is much <1%.

-

3.

The results show that the addition of Ti causes no significant deleterious influence on the mechanical properties of thin-walled CGI castings. Good mechanical properties may predispose thin-walled CGI castings for potential use as substitutes for aluminum alloy castings in diverse applications.

References

S. Dawson, I. Hollinger, M. Robbins, J. Daeth, U. Reuter, and H. Schultz, The Effect of Metallurgical Variables on the Machinability of Compacted Graphite Iron, Society of Automotive Engineers, Inc., 2001. http://www.uscti.com/u_pages/publications/pdfs/ItemETheEffectOfMetallurgicalVariablesOnMachinabilityCGI2001AEIStark.pdf

A. Behera and S.C. Mishra, New Solution for Property Improvement of Automobile Parts, Proceedings of Advances in Simulation & Optimization Techniques in Mechanical Engineering (NASOME-2012), 2012, p 1–5

W. Guesser, T. Schroeder, and S. Dawson, Production Experience with Compacted Graphite Iron Automotive Components, AFS Trans., 2001, 01–071, p 1–11

H. Qiu and Z. Chen, The Forty Years of Vermicular Graphite Cast Iron Development in China (Part III), China Foundry, 2007, 4, p 261–269

J. Liu and N.X. Ding, Effect of Type and Amount of Treatment Alloy on Compacted Graphite Produced by the Flotret Process, AFS Trans., 1985, 93, p 675–688

S. Dawson and T. Schroeder, Practical Applications for Compacted Graphite Iron, AFS Trans., 2004, 47(5), p 1–9

S. Charoenvilaisiri, D.M. Stefanescu, R. Ruxanda, and T.S. Piwonka, Thin Wall Compacted Graphite Iron Castings, AFS Trans., 2002, 110, p 1113–1130

L. Sofroni, I. Riposan, and I. Chria, Some Considerations on the Crystallization Features of Cast Irons with Intermediate-Shaped Graphite (Vermicular Type), Proceedings of the 2nd International Symposium on the Metallurgy of Cast Iron, Geneva, 1974, p 179–196

C. Podrzucki and A. Wojtysiak, Unalloyed Ductile Iron. Part II, Cast Iron with Vermicular Graphite, AGH, Kraków, 1988 (in Polish)

M. Górny, Structure Formation of Ultra-Thin Wall Ductile Iron Castings, Akapit, Cracow, 2010 (in Polish)

J. Zhou, Colour Metallography of Cast Iron, China Foundry, 2011, 8(1), p 154–165

I. Riposan, M. Chisamera, R. Kelley, M. Barstow, and R.L. Naro, Magnesium-Sulfur Relationships in Ductile and Compacted Graphite Cast Irons as Influenced by Late Sulfur Additions, AFS Trans., 2003, 111, p 869–883

Y. Shy, C. Hsu, S. Lee, and C. Hou, Effects of Titanium Addition and Section Size on Microstructure and Mechanical Properties of Compacted Graphite Cast Iron, Mater. Sci. Eng., 2000, A278, p 54–60

American Society for Testing Materials; ASTM A842-85. Standard Specification for Compacted Graphite Iron Casting, 2009. www.astm.org

E. Fraś and M. Górny, Fading of Inoculation Effects in Ductile Iron, Arch. Foundry Eng., 2008, 8(1), p 83–87

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Górny, M., Kawalec, M. Effects of Titanium Addition on Microstructure and Mechanical Properties of Thin-Walled Compacted Graphite Iron Castings. J. of Materi Eng and Perform 22, 1519–1524 (2013). https://doi.org/10.1007/s11665-012-0432-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-012-0432-8