Abstract

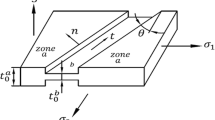

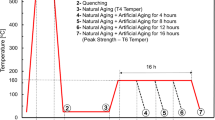

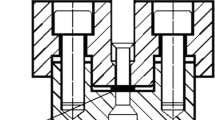

Lightweight materials have been widely used in aerospace, automobile industries to meet the requirement of structural weight reduction. Due to their limited plasticity at room temperature, however, lightweight materials always exhibit distinctly poor forming capability in comparison with conventional deep drawing steels. Based on the phenomenon that the superimposed hydrostatic pressure can improve the plasticity of metal, many kinds of double-sided pressure forming processes have been proposed. In the present study, the Gurson-Tvergaard-Needleman (GTN) damage model combined with finite element method is used to investigate the influence of double-sided pressure on the deformation behavior of biaxially stretched AA6111-T4 sheet metal, including nucleation and growth of microvoids, evaluation of stress triaxiality, and so forth. The Marciniak-Kuczynski (M-K) localized necking model is used to predict the right-hand side of the forming limit diagram (FLD) of sheet metal under superimposed double-sided pressure. It is found that the superimposed double-sided pressure has no obvious effect on the nucleation of microvoids. However, the superimposed double-sided pressure can suppress the growth and coalescence of microvoids. The forming limit curve (FLC) of the biaxially stretched AA6111-T4 sheet metal under the superimposed double-sided pressure is improved and the fracture locus shifts to the left. Furthermore, the formability increase value is sensitive to the strain path.

Similar content being viewed by others

References

Y. Kurihara, Vehicle Weight Reduction Obtained With Lightweight Materials, JSME Int. J. Ser. A Solid Mech. Mater. Eng., 1995, 38(4), p 487–493

J.P. Immarigeon, R.T. Holt, A.K. Koul et al., Lightweight Materials for Aircraft Applications, Mater. Charact., 1995, 35(1), p 41–67

J.J. Lewandowski and P. Lowhaphandu, Effects of Hydrostatic Pressure on Mechanical Behaviour and Deformation Processing of Materials, Int. Mater. Rev., 1998, 43(4), p 145–187

A.S. Kao, H.A. Kuhn, O. Richmond et al., Workability of 1045 Spheroidized Steel Under Superimposed Hydrostatic Pressure, Metall. Trans. A, 1989, 20(9), p 1735–1741

W.A. Spitzig and O. Richmond, The Effect of Pressure on the Flow Stress of Metals, Acta Metall., 1984, 32(3), p 457–463

M. Gotoh, T. Chung, and N. Iwata, Effect of Out-of-Plane Stress on the Forming Limit Strain of Sheet Metals, JSME Int. J. Ser. A Solid Mech. Mater. Eng., 1995, 38(1), p 123–132

L.M. Smith, R.C. Averill, J.P. Lucas et al., Influence of Transverse Normal Stress on Sheet Metal Formability, Int. J. Plast., 2003, 19(10), p 1567–1583

P.H. Matin and L.M. Smith, Practical Limitations to the Influence of Through-Thickness Normal Stress on Sheet Metal Formability, Int. J. Plast., 2005, 21, p 671–690

P.D. Wu, J.D. Embury, D.J. Lloyd et al., Effects of Superimposed Hydrostatic Pressure on Sheet Metal Formability, Int. J. Plast., 2009, 25(9), p 1711–1725

L.M. Smith, S. Ganeshmurthy, and K. Alladi, Double-Sided High-Pressure Tubular Hydroforming, J. Mater. Process. Technol., 2003, 142(3), p 599–608

N. Jain and J. Wang, Plastic Instability in Dual-Pressure Tube-Hydroforming Process, Int. J. Mech. Sci., 2005, 47(12), p 1827–1837

J. Liu, B. Westhoff, M.A. Ahmetoglu et al., Application of Viscous Pressure Forming (VPF) to Low Volume Stamping of Difficult-to-Form Alloys—Results of Preliminary FEM Simulations, J. Mater. Process. Technol., 1996, 59(1–2 special issue), p 49–58

Z.J. Wang, H. Song, and Z. Wang, Deformation Behavior of TC1 Titanium Alloy Sheet Under Double-Sided Pressure, Trans. Nonferrous Met. Soc. China, 2008, 18(1), p 72–76

Z.J. Wang, Z. Wang, and M.X. Li, Failure Analysis of Al1060 Sheets Under Double-Sided Pressure Deformation Conditions, Key Eng. Mater., 2007, 353–358(Part 1), p 603–606

F. Ozturk and D. Lee, A New Methodology for Ductile Fracture Criteria to Predict the Forming Limits, J. Mater. Eng. Perform., 2007, 16(2), p 224–228

C. Vallellano, D. Morales, and F.J. Garcia-Lomas, A Study to Predict Failure in Biaxially Stretched Sheets of Aluminum Alloy 2024-T3, Mater. Manuf. Process., 2008, 23(3–4), p 303–310

Z.Q. Yu, Z.Q. Lin, and Y.X. Zhao, Evaluation of Fracture Limit in Automotive Aluminum Alloy Sheet Forming, Mater. Des., 2007, 28(1), p 203–207

W.J. Song, S.W. Kim, J. Kim et al., Analytical and Numerical Analysis of Bursting Failure Prediction in Tube Hydroforming, J. Mater. Process. Technol., 2005, 164, p 1618–1623

M. Jain, J. Allin, and D.J. Lloyd, Fracture Limit Prediction Using Ductile Fracture Criteria for Forming of an Automotive Aluminum Sheet, Int. J. Mech. Sci., 1999, 41, p 1273–1288

V. Tvergaard and A. Needleman, Analysis of the Cup-Cone Fracture in a Round Tensile Bar, Acta Metall., 1984, 32(1), p 157–169

K.C. Liao, Applications of Anisotropic Yield Criteria to Porous Sheet Metal Forming Simulations, Mater. Des., 2008, 29(5), p 1000–1010

W.B. Lievers, A.K. Pilkey, and D.J. Lloyd, Using Incremental Forming to Calibrate a Void Nucleation Model for Automotive Aluminum Sheet Alloys, Acta Mater., 2004, 52(10), p 3001–3007

Z. Chen and X. Dong, The GTN Damage Model Based on Hill’48 Anisotropic Yield Criterion and Its Application in Sheet Metal Forming, Comput. Mater. Sci., 2009, 44(3), p 1013–1021

V. Uthaisangsuk, U. Prahl, S. Munstermann et al., Experimental and Numerical Failure Criterion for Formability Prediction in Sheet Metal Forming, Comput. Mater. Sci., 2008, 43(1), p 43–50

A.A. Zadpoor, J. Sinke, and R. Benedictus, Formability Prediction of High Strength Aluminum Sheets, Int. J. Plast., 2009, 25(12), p 2269–2297

Z. Marciniak, K. Kuczynski, and T. Pokora, Influence of the Plastic Properties of a Material on the Forming Limit Diagram for Sheet Metal in Tension, Int. J. Mech. Sci., 1973, 15(10), p 789–800

S.G. Xu and K.J. Weinmann, On predicting Forming Limits Using Hill’s Yield Criteria, J. Mater. Eng. Perform., 2000, 9(2), p 174–182

A. Assempour, R. Hashemi, K. Abrinia et al., A Methodology for Prediction of Forming Limit Stress Diagrams Considering the Strain Path Effect, Comput. Mater. Sci., 2009, 45(2), p 195–204

S. Ahmadi, A.R. Eivani, and A. Akbarzadeh, An Experimental and Theoretical Study on the Prediction of Forming Limit Diagrams Using New BBC Yield Criteria and M-K Analysis, Comput. Mater. Sci., 2009, 44(4), p 1272–1280

A. Needleman and N. Triantafyllidis, Void Growth and Local Necking in Biaxially Stretched Sheets, J. Eng. Mater. Technol. (Trans. ASME), 1978, 100(2), p 164–169

C.H.M. Simha, R. Grantab, and M.J. Worswick, Computational Analysis of Stress-Based Forming Limit Curves, Int. J. Solids Struct., 2007, 44(25–26), p 8663–8684

D. Banabic and S. Soare, On the Effect of the Normal Pressure Upon the Forming Limit Strains, Proceedings Numisheet 2008, P. Hora, Ed., Switzerland (2008)

R. Hill, A Theory of Yielding and Plastic Flow of Anisotropic Metals, Proc. R. Soc. Lond. A, 1927, 193, p 281–297

A. Needleman and V. Tvergaard, An Analysis of Ductile Rupture in Notched Bars, J. Mech. Phys. Solids, 1984, 32(6), p 461–490

ABAQUS Analysis User’s Manual (Version 6.7) (2007)

C.C. Chu and A. Needleman, Void Nucleation Effects in Biaxially Stretched Sheets, J. Eng. Mater. Technol. Trans. ASME, 1980, 102(3), p 249–256

N. Aravas, On the Numerical Integration of a Class of Pressure-Dependent Plasticity Models, Int. J. Numer. Methods Eng., 1987, 24(7), p 1395–1416

Y.B. Bao and T. Wierzbicki, On the Cut-Off Value of Negative Triaxiality for Fracture, Eng. Fract. Mech., 2005, 72(7), p 1049–1069

Acknowledgments

The authors would like to thank the Natural Science Foundation of China (No. 50805034) and the postdoctoral foundation of China (No. 20100471028) for the support given to this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, J., Wang, Z. & Meng, Q. Numerical Investigations on the Influence of Superimposed Double-Sided Pressure on the Formability of Biaxially Stretched AA6111-T4 Sheet Metal. J. of Materi Eng and Perform 21, 429–436 (2012). https://doi.org/10.1007/s11665-011-9941-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-011-9941-0