Abstract

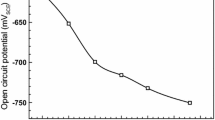

This work investigated the effects of chloride ions and hydrogen-charging on the passivity and pitting corrosion behavior of X80 pipeline steel in a bicarbonate-carbonate solution by electrochemical and photo-electrochemical techniques. It was found that a stable passivity can be established on the steel in the absence and presence of chloride ions. The hydrogen-charging does not alter the transpassive potential, but increases the passive current density. When chloride ions are contained in the solution, pitting corrosion will be initiated. The pitting potential is independent of the hydrogen-charging. Hydrogen-charging would enhance the anodic dissolution and electrochemical activity of the steel, but does not affect the pitting potential, which indicates that the charged hydrogen is not involved in the pitting initiation. However, hydrogen may accelerate the pit growth. Photo illumination could enhance the activity of the steel electrode, resulting in an increase of photo-induced anodic current density.

Similar content being viewed by others

References

M. Baker Jr., Stress Corrosion Cracking Studies, Integrity Management Program DTRS56-02-D-70036, Department of Transportation, Office of Pipeline Safety, USA, 2004

Canadian National Energy Board, Report of Public Inquiry Concerning Stress Corrosion Cracking on Canadian Oil and Gas Pipelines, MH-2-95, November 1996

R.N. Parkins, A Review of Stress Corrosion Cracking of High-Pressure Gas Pipelines, Corrosion 2000, NACE, Houston, 2000 (paper no. 363)

A.Q. Fu, X. Tang, and Y.F. Cheng, Characterization of Corrosion of X70 Pipeline Steel in Thin Electrolyte Layer Under Disbonded Coating by Scanning Kelvin Probe, Corros. Sci., 2009, 51, p 186–190

X. Tang and Y.F. Cheng, Localized Dissolution Electrochemistry at Surface Irregularities of Pipeline Steel, Appl. Surf. Sci., 2008, 254, p 5199–5205

M.C. Li and Y.F. Cheng, Corrosion of the Stressed Pipe Steel in Carbonate-Bicarbonate Solution Studied by Scanning Localized Electrochemical Impedance Spectroscopy, Electrochim. Acta, 2008, 53, p 2831–2836

C.W. Du, X.G. Li, P. Liang, Z.Y. Liu, G.F. Jia, and Y.F. Cheng, Effects of Microstructure on Corrosion of X70 Pipe Steel in an Alkaline Soil, J. Mater. Eng. Perform., 2009, 18, p 216–220

F.M. Song, Predicting the Mechanisms and Crack Growth Rates of Pipelines Undergoing SCC at High pH, Corros. Sci., 2009, 51, p 2657–2674

R.N. Parkins, Predictive Approaches to Stress Corrosion Cracking, Corros. Sci., 1980, 22, p 147–166

R.N. Parkins, Realistic Stress Corrosion Crack Velocities for Life Prediction Estimates, Life Prediction of Corrodible Structures, Vol 1, R.N. Parkins, Ed., NACE International, Houston, TX, 1994, p 97–112

R.N. Parkins, Overview of Intergranular Stress Corrosion Cracking Research Activities, Line Pipe Research Supervisory Committee of the Pipeline Research Committee of the American Gas Association, PR-232-9401, May 1994

G.A. Zhang and Y.F. Cheng, Micro-Electrochemical Characterization of Corrosion of Pre-cracked X70 Pipeline Steel in a Concentrated Carbonate/Bicarbonate Solution, Corros. Sci., 2010, 52, p 960–968

R.N. Parkins, Conceptual Understanding and Life Prediction for SCC of Pipelines, Proceedings of Corrosion 96, Research Topical Symposia, P.L. Andresen and R.N. Parkins, Ed., NACE International, Houston, TX, 1996, p 1–17

R.N. Parkins, Prevention and Control of Stress Corrosion Cracking—An Overview, Corrosion 1985, NACE, Houston, 1985 (paper no. 348)

R.N. Parkins and R.R. Fessler, Line Pipe Stress Corrosion Cracking—Mechanisms and Remedies, Corrosion 1986, NACE, Houston, 1986 (paper no. 320)

J.A. Beavers and B.A. Harle, Mechanisms of High-pH and Near-Neutral-pH SCC of Underground Pipelines, International Pipeline Conference, Vol 1, ASME, 1996, p 555–568

D.H. Davies and G.T. Burstein, The Effects of Bicarbonate on the Corrosion and Passivation of Iron, Corrosion, 1980, 36, p 416–422

R.N. Parkins and S. Zhou, The Stress Corrosion Cracking of C-Mn Steel in CO2-HCO3-CO3 2− Solutions. I: Stress Corrosion Data, Corros. Sci., 1997, 39, p 159–173

R.N. Parkins and S. Zhou, The Stress Corrosion Cracking of C-Mn Steel in CO2-HCO3-CO3 2− Solutions. II: Electrochemical and Other Data, Corros. Sci., 1997, 39, p 175–191

G. van Boven, W. Chen, and R. Rogge, The Role of Residual Stress in Neutral pH SCC of Pipeline Steels Part I: Pitting and Cracking Occurrence, Acta Mater., 2007, 55, p 29–42

W. Chen, F. King, and E. Vokes, Characteristics of Near Neutral pH Stress Corrosion Cracks in an X-65 Pipeline Steel, Corrosion, 2002, 58, p 267–275

M.Z. Yang, J.L. Luo, and B.M. Patchet, Correlation of Hydrogen-Facilitated Pitting of AISI, 304 Stainless Steel to Semiconductivity of Passive Film, Thin Solid Films, 1999, 354, p 142–147

A.A. Valeria and M.A. Christopher Brett, Characterisation of Passive Films Formed on Mild Steels in Bicarbonate Solution by EIS, Electrochim. Acta, 2002, 47, p 2081–2091

D.G. Li, Y.R. Feng, Z.Q. Bai, J.W. Zhua, and M.S. Zheng, Influence of Temperature Chloride Ions and Chromium Element on the Electronic Property of Passive Film Formed on Carbon Steel in Bicarbonate/Carbonate Buffer Solution, Electrochim. Acta, 2007, 52, p 7877–7884

Y.F. Cheng and J.L. Luo, Electronic Structure and Pitting Susceptibility of Passive Film on Carbon Steel, Electrochim. Acta, 1999, 44, p 2947–2956

Y.F. Cheng and J.L. Luo, Comparison of Pitting Susceptibility and Semiconducting Properties of the Passive Films on Carbon Steel in Chromate and Bicarbonate Solutions, Appl. Surf. Sci., 2000, 167, p 113–121

M.D. Cunha Belo, N.E. Hakiki, and M.G.S. Ferreira, Semiconducting Properties of Passive Films Formed on Nickel-Base Alloys Type 600: Influence of the Alloying Elements, Electrochim. Acta, 1999, 44, p 2473–2481

J.W. Schultze and M.M. Lohrengel, Stability Reactivity and Breakdown of Passive Films: Problems of Recent and Future Research, Electrochim. Acta, 2000, 45, p 2499–2513

M.E. Armacanqui and R.A. Oriani, Effect of Hydrogen on the Pitting Resistance of Passivating Film on Nickel in Chloride-Containing, Corrosion, 1988, 44, p 696–698

Q. Yang and J.L. Luo, Effects of Hydrogen on Disorder of Passive Films and Pitting Susceptibility of Type 310 Stainless Steel, J. Electrochem. Soc., 2001, 148, p B29–B35

H. Yashiro, B. Pound, N. Kumagai, and K. Tanno, The Effect of Permeated Hydrogen on the Pitting of Type 304 Stainless Steel, Corros. Sci., 1998, 40, p 781–791

L. Zhang, X.G. Li, C.W. Du, and Y.F. Cheng, Corrosion and Stress Corrosion Cracking Behavior of X70 Pipeline Steel in a CO2-Containing Solution, J. Mater. Eng. Perform., 2009, 18, p 319–323

J.G. Yu, J.L. Luo, and P.R. Norton, Electrochemical Investigation of the Effects of Hydrogen on the Stability of the Passive Film on Iron, Electrochim. Acta, 2002, 47, p 1527–1536

S. Ningshen, U.K. Mudali, and G. Amarend, Hydrogen Effects on the Passive Film Formation and Pitting Susceptibility of Nitrogen Containing Type 316L Stainless Steels, Corros. Sci., 2006, 48, p 1106–1121

G. Razzini, M. Cabrini, S. Maffi, G. Mussati, and L. Peraldo Bicelli, Photoelectrochemical Visualization in Real-Time of Hydrogen Distribution in Plastic Regions of Low-Carbon Steel, Corros. Sci., 1999, 41, p 203–209

G. Razzini, S. Maffi, G. Mussati, and L. Peraldo Bicelli, The Scanning Photoelectrochemical Microscopy of Diffusing Hydrogen into Metals, Corros. Sci., 1995, 37, p 1131–1141

G. Razzini, S. Maffi, G. Mussati, L. Peraldo Bicelli, and G. Mitsi, Photo-Electrochemical Imaging of Hydrogen-Induced Damage in Stainless Steel, Corros. Sci., 1997, 39, p 613–620

S. Maffi, C. Lenardi, and B. Bozzini, Photoelectrochemical Imaging of Non-Planar Surfaces: The Influence of Geometrical and Optical Factors on Image Formation, Meas. Sci. Technol., 2002, 13, p 1398–1403

Y.M. Zeng and J.L. Luo, Electronic Band Structure of Passive Film on X70 Pipeline Steel, Electrochim. Acta, 2003, 48, p 3551–3562

Y.M. Zeng, J.L. Luo, and P.R. Norton, A Study of Semiconducting Properties of Hydrogen Containing Passive Films, Thin Solid Films, 2004, 460, p 116–124

K.T. Corbett, B.R. Bowen, and C.W. Petersen, High Strength Steel Pipeline Economics, Int. J. Offshore Polar Eng., 2004, 14, p 36–38

G.A. Zhang and Y.F. Cheng, Micro-Electrochemical Characterization and Mott-Schottky Analysis of Corrosion of Welded X70 Pipeline Steel in Carbonate/Bicarbonate Solution, Electrochim. Acta, 2009, 55, p 316–324

C. DeWaard and D.E. Milliams, Carbonic Acid Corrosion of Steel, Corrosion, 1975, 31, p 177–181

J.K. Heuer and J.F. Stubbins, An XPS Characterization of FeCO3 Films from CO2 Corrosion, Corros. Sci., 1999, 41, p 1231–1243

J.O.M. Bockris and D. Drazic, The Electrode Kinetics of the Deposition and Dissolution of Iron, Electrochim. Acta, 1962, 7, p 293–313

B.R. Linter and G.T. Burstein, Reaction of Pipeline Steel in Carbon Dioxide Solution, Corros. Sci., 1999, 41, p 117–139

P. Li, T.C. Tan, and J.Y. Lee, Impedance Spectra of the Anodic Dissolution of Mild Steel in Sulfuric Acid, Corros. Sci., 1996, 38, p 1935–1955

Y.F. Cheng, M. Wilmott, and J.L. Luo, The Role of Chloride Ions in Pitting of Carbon Steel Studied by Statistical Analysis of Electrochemical Noise, Appl. Surf. Sci., 1999, 152, p 161–168

D.D. Macdonald, Passivity—the Key to Our Metals-Based Civilization, Pure Appl. Chem., 1999, 71, p 951–986

D.D. Macdonald, Point Defect Model for the Passive State, J. Electrochem. Soc., 1992, 139, p 3434–3449

M.C. Li and Y.F. Cheng, Mechanistic Investigation of Hydrogen-Enhanced Anodic Dissolution of X-70 Pipe Steel and its Implication on Near-Neutral pH SCC of Pipelines, Electrochim. Acta, 2007, 52, p 8111–8117

Z. Qin, P.R. Norton, and J.L. Luo, Effects of Hydrogen on Formation of Passive Films on AISI, 310 Stainless Steel, Br. Corros. J., 2001, 36, p 33–42

D. Wallinder, G. Hultquist, and B. Tventen, Hydrogen in Chromium: Influence on Corrosion Potential and Anodic Dissolution in Neutral NaCl Solution, Corros. Sci., 2001, 43, p 1267–1271

Acknowledgment

This work was supported by Canada Research Chairs Program and Natural Science and Engineering Research Council of Canada (NSERC).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xue, H.B., Cheng, Y.F. Passivity and Pitting Corrosion of X80 Pipeline Steel in Carbonate/Bicarbonate Solution Studied by Electrochemical Measurements. J. of Materi Eng and Perform 19, 1311–1317 (2010). https://doi.org/10.1007/s11665-010-9631-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-010-9631-3