Abstract

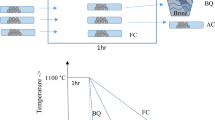

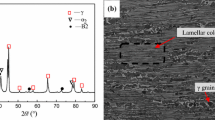

Transformation superplastic forming is an attractive alternative forming technique to microstructural superplastic forming, since it requires no special microstructures and, therefore, eliminates the limitation of superplastic forming capability to only expensive materials with stable high-temperature fine grains. Transformation superplasticity occurs through biasing the internal stress produced from an allotropic phase transformation by a small external stress. In this work, finite element modeling was implemented to study the transformation superplastic forming of domes from flat circular thin plate samples. The evolution and distribution of stress, strain, and dome thickness was analyzed in detail. The thickness distributions in the formed domes were compared with the theoretical predictions of two models, which assume different stress states in the domes. The appropriate stress state was identified through this comparison. Different gas pressure amplitudes were applied during forming to investigate the effect on the formed-dome apex height, when the forming time was fixed.

Similar content being viewed by others

References

T.G. Nieh, J. Wadsworth, and O.D. Sherby, Superplasticity in Metals and Ceramics, 1st ed., Cambridge University Press, 2005

M. Kawasaki, R.B. Figueiredo, C. Xu, T.G. Langdon, Developing Superplastic Ductilities in Ultrafine-grained Metals, Metall. Mater. Trans. A, 2007, 38A, 1891–1898

M. Kawasaki, T.G. Langdon, Principles of Superplasticity in Ultrafine-grained Materials, J. Mater. Sci., 2007, 42, 1782–1796

S.V. Dobatkin, E.N. Bastarache, G. Sakai, T. Fujita, Z. Horita, T.G. Langdon, Grain Refinement and Superplastic Flow in an Aluminum Alloy Processed by High-pressure Torsion, Mater. Sci. Eng. A, 2005, 408, p 141–146

C.Y. Gao, P. Lours, G. Bernhart, Thermomechanical Stress Analysis of Superplastic Forming Tool, J. Mater. Process. Technol., 2005, 169, 281–291

A. Dutta, I. Charit, L.B. Johannes, R.S. Mishra, Deep Cup Forming by Superplastic Punch Stretching of Friction Stir Processed 7075 Al Alloy, Mater. Sci. Eng. A, 2005, 395, 173–179

C. Xu, M. Furukawa, Z. Horita, T.G. Langdon, Developing a Superplastic Forming Capability in Nanometals, Solid State Phenom., 2005, 101-102, 23–30

Y.T. Zhu, T.G. Langdon, The Fundamentals of Nanostructured Materials Processed by Severe Plastic Deformation, JOM, 2004, 56, 58–63

M. Kamachi, M. Furukawa, Z. Horita, T.G. Langdon, Achieving Superplasticity of Al-1%Mg-0.2%Sc Alloy in Plate Samples Processed by Equal-channel Angular Pressing, Mater. Trans., 2004, 45, 2521–2524

Y.T. Zhu, T.C. Lowe, T.G. Langdon, Performance and Applications of Nanostructured Materials Produced by Severe Plastic Deformation, Scripta Mater., 2004, 51, 825–830

V.N. Perevezentsev, V.N. Chuvil’deev, V.I. Kopylov, A.N. Sysoev, T.G. Langdon, Developing High Strain Rate Superplasticity in Al-Mg-Sc-Zr Alloys Using Equal-channel Angular Pressing, Ann. Chim.-Sci. Mater., 2002, 27, 99–109

A.V. Sergueeva, N.A. Mara, A.K. Mukherjee, Plasticity at Really Diminished Length Scales, Mater. Sci. Eng. A, 2007, 463, 8–13

N.A. Mara, A.V. Sergueeva, T.D. Mara, S.X. McFadden, A.K. Mukherjee, Superplasticity and Cooperative Grain Boundary Sliding in Nanocrystalline Ni3Al, Mater. Sci. Eng. A, 2007, 463, 238–244

R.Z. Valiev, A.V. Sergueeva, A.K. Mukherjee, The Effect of Annealing on Tensile Deformation Behavior of Nanostructured SPD Titanium, Scripta Mater., 2003, 49, 669–674

X. Zhang, H. Wang, R.O. Scattergood, J. Narayan, C.C. Koch, A.V. Sergueeva, A.K. Mukherjee, Studies of Deformation Mechanisms in Ultra-fine-grained and Nanostructured Zn, Acta Mater., 2002, 50, 4823–4830

G.W. Greenwood, R.H. Johnson, The Deformation of Metals Under Small Stresses During Phase Transformations, Proc. Roy. Soc. Lond. A, 1965, 283, 403–422

S.M. Pickard, B. Derby, The Influence of Microstructure on Internal-Stress Superplasticity in Polycrystalline Zinc, Scripta Metall. Mater., 1991, 25, 467–472

B. Derby, The Mechanism of Internal Stress Superplasticity, in Superplasticity in Metals, Ceramics and Intermetallics, M.J. Mayo, M. Kobayashi, and J. Wadsworth, Eds., MRS, 1990

H. Zhang, G.S. Daehn, R.H. Wagoner, Simulation of the Plastic Response of Whisker Reinforced Metal Matrix Composites Under Thermal Cycling Conditions, Scripta Metall. Mater., 1991, 25, 2285–2290

D.C. Dunand, P. Zwigl, Hydrogen-Induced Internal-Stress Plasticity in Titanium, Metall. Mater. Trans. A, 2001, 32, 841–843

C. Schuh, D.C. Dunand, Internal Stress Plasticity due to Chemical Stresses, Acta Mater., 2001, 49, 3387–3400

Q. Li, E. Chen, D. Bice, D.C. Dunand, Transformation Superplasticity of Cast Titanium and Ti-6Al-4V, Metall. Mater. Trans. A, 2007, 38A, p 44–53

M. Frary, C. Schuh, D.C. Dunand, Kinetics of Biaxial Dome Formation by Transformation Superplasticity of Titanium Alloys and Composites, Metall. Mater. Trans. A, 2002, 33, p 1669–1680

P. Villars, A. Prince, and H. Okamoto, Handbook of Ternary Alloy Phase Diagrams, ASM International, 1995

J.A. Ewing, The Strength of Materials, 2nd ed., University Press, 1906

R.T. Fenner, Mechanics of Solids, 1st ed., CRC, 1999

F.U. Enikeev, A.A. Kruglov, An Analysis of the Superplastic Forming of a Thin Circular Diaphragm, Int. J. Mech. Sci., 1995, 37, p 473–483

A.R. Ragab, Thermoforming of Superplastic Sheet in Shaped Dies, Met. Technol., 1983, 10, p 340–348

Acknowledgment

The support form University of Nevada, Reno is greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article was presented at Materials Science & Technology 2007, Automotive and Ground Vehicles symposium held September 16-20, 2007, in Detroit, MI.

Rights and permissions

About this article

Cite this article

Li, Q. Modeling of Transformation Superplastic Forming of Ti Alloys. J. of Materi Eng and Perform 17, 363–368 (2008). https://doi.org/10.1007/s11665-008-9214-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-008-9214-8