Abstract

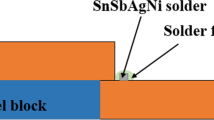

Tin-silver-bismuth solder is characterized by its lower melting point, good wetting behavior, and good mechanical property for which it is expected to be a new lead-free solder to replace tin-lead solder. In this article, Sn-3.33Ag-4.83Bi solder was investigated concerning its physical, spreading, and mechanical properties under specific conditions. Cooling curves and DSC results showed that it was close to eutectic composition (m.p. 210°–212 °C). Coefficiency of thermal expansion (CTE) of this solder, between that of PCBs and copper substrates, was beneficial to alleviate the thermal mismatch of the substrates. It was also a good electrical and thermal conductor. Using a rosin-based, mildly activated (RMA) flux, a spreading test indicated that SnAgBi solder paste had good solderability. Meanwhile, the solder had high tensile strength and fracture energy. Its fracture mechanism was a mixture of ductile and brittle fracture morphology. The metallographic and EDAX analyses indicated that it was composed of a tin-based solid solution and some intermetallic compound (IMC) that could strengthen the substrate. However, these large needle-like IMCs would cut the substrate and this resulted in the decreasing of the toughness of the solder.

Similar content being viewed by others

References

Laura J. Turbini, Gregory C. Munie, Dennis Bernier, Jürgen Gamalski, and David W. Bergman: “Examining the Environmental Impact of Lead-Free Soldering Alternatives,” IEEE Transactions on Electronics Packaging Manufacturing, 24(1), pp. 4–9.

Chad M. Miller, Iver E. Anderson, and Jack F. Smith: “A Viable Tin-Lead Solder Substitute: Sn-Ag-Cu,” J. Electron. Mater., 1994, 23(7), pp. 595–601.

Bill Trumble: “Get the Lead Out,” IEEE SPECTRUM, May 1998, pp. 55–60.

Fujitsu Targets 2002 for Eliminating of Lead from Products, downloaded from www.lead-free.org/Soldering Technology for the new millennium.

Paul T. Vianco and Darrel R. Frear: “Issues in the Replacement of Lead-Bearing Solders” (overview), JOM, July 1993, pp. 14–19.

M. McCormack, G.W. Kammlott, H.S. Chen, and S. Jin: “New Lead-Free Sn-Ag-Zn-Cu Solder Alloy with Improved Mechanical Properties,” Appl. Phys. Lett., 5 September 1994, 65(10), pp. 1233–35.

Yoshiharu Kariya and Masahisa Otsuka: “Mechanical Fatigue Characteristic of Sn-3.5Ag-X (X=Bi, Cu, Zn, and In) Solder Alloys, J. Electron. Mater., 1998, 27(11), pp. 1229–35.

Dr. Ning-Cheng Lee: “A Thorough Look at Lead-Free Solder Alternatives,” Circuits Assembly, April 1998, pp. 64–71.

Walter L. Winterbottom: “Converting to Lead-Free Solders: An Automotive Industry Perspective,” JOM, July 1993, pp. 20–24.

Zhang Qiyun and Zhuang Honhshou: “Manual of Brazing and Soldering,” Mechanical Industrial Press, ISBN 7-111-06929-3, January, 1999, Beijing.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Xia, Z., Shi, Y. & Chen, Z. Evaluation on the characteristics of tin-silver-bismuth solder. J. of Materi Eng and Perform 11, 107–111 (2002). https://doi.org/10.1007/s11665-002-0016-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-002-0016-0