Abstract

We report an organic luminescent small molecule, Bis(1-phenylisoquinoline) (acetylacetonate) iridium(III) or Ir(piq)2(acac), that can function as a stable and efficient hole selective contact (HSC) for crystalline silicon (c-Si) solar cells. The devices with the Ir(piq)2(acac) HSC exhibit superior charge transport properties and high stability for up to 30 days in the air without packaging. The photovoltaic characteristics with the solution-processed Ir(piq)2(acac) HSC exhibit little dependence on the blade coating speed and film thickness, demonstrating tolerance to coating and thickness variations. Moreover, the series resistance of the solar cells and the surface work function of the Ir(piq)2(acac) HSCs exhibit analogous correlations to the annealing temperature, suggesting that the fill factor (FF) enhancement originates from an upward energy band bending and a reduced barrier height which facilitates hole transport and collection. The conventional c-Si solar cell incorporating an Ir(piq)2(acac) HSC achieves a 17.8% power conversion efficiency (PCE) with a 78.9% FF, both exceeding the reference counterpart with a 16.9% PCE and 76.8% FF. This work opens up possibilities for exploring a variety of organic luminescent small molecules as efficient hole selective contacts in high-efficiency and low-cost silicon photovoltaics.

Graphic Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

As global photovoltaic installations have experienced rapid growth over the past few years, the power conversion efficiency (PCE) of the mainstream crystalline silicon (c-Si) solar cell has also steadily progressed towards its theoretical limit, with reduced production costs and boosted reliability.1 These advances have mainly benefitted from the increased understanding of fundamental device physics and material properties. The PCE of a photovoltaic device is characterized by absorption, interface passivation, and carrier-selective transport properties. Of the influencing factors, the carrier-selective contacts (CSCs), in particular, have garnered significant research interest in the recent past.2,3,4 Various c-Si solar cells that achieve record PCEs of over 25%, including the heterojunction with interdigitated back contacts,5 tunnel oxide passivated contacts,6 polycrystalline silicon on oxide solar cells,7 and so on, have implemented efficient CSCs with a low contact resistivity to deliver a high fill factor (FF) and external open-circuit voltage (Voc). In these devices, heavily doped amorphous and polycrystalline silicon serves as the CSCs. However, the doped CSC layer can still encounter parasitic photon absorption and thermal instability.8,9 In addition, energy-consuming diffusion or vacuum deposition processes have spurred further efforts on dopant-free CSCs, which now include a variety of transition metal oxides, alkaline metal salts, organic polymers, and dipole materials, such as amino acids, etc.10,11,12,13,14,15,16,17,18,19,20 Organic materials functioning as hole- or electron-selective contacts (HSCs or ESCs) have gained much attention due to their scalability and capacity for low-temperature solution processing. Efficient silicon solar cells with organic ESCs and HSCs have been reported, with PCEs ranging between 17.9% and 20.6%; however, the reliability issue has hardly been addressed and remains a technological barrier to the deployment of organic CSCs in silicon photovoltaics. In this work, we report an organic luminescent small molecule, Bis(1-phenylisoquinoline) (acetylacetonate)iridium(III) or Ir(piq)2(acac), that can function as an efficient HSC for conventional phosphorus oxychloride (POCl3)-diffused c-Si solar cells with superior charge transport characteristics and device stability.

The varieties of luminescent organic materials, including polymers and small molecules, have blossomed during the last two decades, and have enabled successful commercial applications of organic light-emitting diodes (OLEDs) for displays and consumer electronics. Among these, phosphorescent materials have a theoretical internal quantum efficiency close to unity compared to fluorescent ones.21 Previously, we found that solution-doped fluorescent organic polymers exhibit excellent hole transport properties for hybrid organic silicon solar cells.22 However, the devices also suffered from instability and short lifetimes. Since the material properties of luminescent small molecules tended to be more stable than those of polymers during the development of OLEDs, in this work, a commercially available, efficient phosphorescent red emitter, the iridium-complex, Ir(piq)2(acac), is investigated as the HSC for silicon solar cells. Ir(piq)2(acac) has a highest occupied molecular orbital (HOMO) level close to the valence band of silicon and a lowest unoccupied molecular orbital (LUMO) level that forms a large band offset to the conduction band of silicon, offering a favorable band alignment for hole selective transport in silicon solar cells. In addition, a blade-coating process using an Ir(piq)2(acac) solution has been developed to fully exploit distinct advantages, such as facile material engineering and scalable fabrication with minimal energy usage and material waste.

Experimental Methods

Material Preparation

Luminescent small molecule Ir(piq)2(acac) was purchased from Lumtec and used as received. The material and sample preparation were conducted in a nitrogen-purged glove box. Ir(piq)2(acac) was dissolved in toluene with a concentration of 1 wt.%. The prepared solutions were heated on a hotplate at 60°C and stirred with a magnetic stirrer at 80 rpm for 12 h until the solution was clear without visible precipitations before application.

Contact and Materials Characterizations

Solar-grade, 2-Ω cm p-type c-Si wafers were cut into tiles with an area of 2.8 × 2.8 cm2, followed by a dip in a dilute hydrofluoric (DHF) acid solution for 15 s and then dried with a nitrogen gun. The c-Si tile that underwent blade coating was first pre-heated at 60°C for 3 min. Then, a blade with a groove spacing of 60 μm was mounted onto an automatically controlled stage, where the blade motion velocity and acceleration were adjusted to control the film thickness. At the beginning of the coating process, a 20-μL organic solution was delivered from a micropipette and dropped underneath the blade. The coating conditions were set to a velocity of 500 mm/s and an acceleration of 200 mm/s2, followed by hotplate annealing at 150°C for 10 min, unless otherwise specified. The thickness of the blade-coated organic thin film was obtained via fitting the spectroscopic ellipsometry data with a Cauchy model (M—2000; J. A. Woollam).

The surface work function of the Ir(piq)2(acac)/c-Si sample was measured by scanning Kelvin probe microscopy (SKPM) (SMENA, NT-MDT). In SKPM, an atomic force microscopy system operates in non-contact mode. A Pt/Ir-coated tip was set to oscillate at the first resonant frequency of the cantilever, ~ 234 kHz, as it is scanned over the sample surface to obtain the topographic data. The scanning rate was set to 1 Hz to minimize noise and ensure that the samples were not damaged during measurement. In addition to the atomic force, a long-range electrostatic force also exists between the tip and the sample, which is determined by the contact potential difference (CPD) between them. The electrostatic force is detected by applying an AC voltage with an amplitude of 1 V (peak to peak) and frequency of 150 kHz to create an oscillating force on the tip, while a lock-in amplifier operating with a sensitivity of 200 mV/nA was used to single out the signal. Additionally, a feedback loop applied a DC bias to the tip in order to nullify the CPD between the probe and the sample. Since the probe’s work function was calibrated with highly oriented pyrolytic graphite (work function = 5 eV) before the sample measurement, the surface work function of the sample was obtained by subtracting the CPD, which is equal to the applied DC bias, from the probe’s work function.

Cell Fabrication and Characterization

The baseline solar cells were fabricated on a 6-inch (c.15.24 cm) solar-grade c-Si wafer with a thickness of 200 μm and a resistivity of 2 Ω cm. The wafers were first immersed in a potassium hydroxide solution (KOH:IPA: H2O = 1:5:130) at 80°C for saw damage removal and alkaline texturing, and then doped through a POCl3 diffusion process to form an n+ emitter with a sheet resistance of ~ 95 Ω cm2. Subsequently, the wafer was floated on a sodium hydroxide solution (NaOH: H2O = 1:2) to remove the rear side emitter and textures, forming a planar surface. The wafer was then diced into tiles with areas of 2.8 × 2.8 cm2 through laser ablation and then dipped into a DHF solution for 18 s, followed by hard baking at 100°C for 10 min. Subsequently, the organic hole-selective material was applied to the rear surface of the cell via blade coating, with the specific coating and annealing conditions, followed by thermal evaporation of a 100-nm-thick silver electrode. Finally, the front surface of the device was thermally evaporated with a 100-nm-thick silver grid in a 2 × 2 cm2 opening window with a 12% metallic shading ratio through shadow masks. The current–voltage characteristics of the solar cells were determined using a class A solar simulator (Newport ) under standard testing conditions (25°C, 1000 W/m2, and AM 1.5 G spectrum).

Results and Discussion

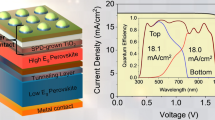

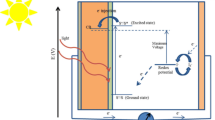

We employed the POCl3-diffused, n+/p c-Si solar cells without an antireflective coating as the test baseline. Figure 1a shows the device schematic, where the Ir(piq)2(acac) HSC is introduced on the rear chemically-polished c-Si surface via blade coating, and covered by a 100-nm-thick, thermally-evaporated silver electrode. The inset shows the molecular structure of the Ir(piq)2(acac) and an image of its solution glowing under ultraviolet (UV) illumination. However, since the HSC is located on the backside of the cell, where UV photons are almost inaccessible, we believe that the charge transport, rather than optical conversion properties of the Ir(piq)2(acac) HSCs, dictate the photovoltaic characteristics. Figure 1b plots the energy diagram of the c-Si solar cell incorporating an Ir(piq)2(acac) HSC. The HOMO level of Ir(piq)2(acac) is 5.14 eV, which is nearly aligned to the valence band of silicon, while the LUMO level is 2.14 eV which offers a large energy barrier to block electron transport.23 Moreover, the image of the rear surface of the solar cell coated with Ir(piq)2(acac) exhibits a homogeneous red luminescence under UV illumination, which also shows the uniformity of our blade-coating process (Fig. 1c). In contrast, the rear surface treated with the solvent toluene does not exhibit photoluminescence and is used as a reference. We further measured the contact resistivity of the Ir(piq)2(acac)/Ag stacks deposited on a polished c-Si wafer, using the transfer length measurement (TLM) method, as shown in Fig. 1d. The Ir(piq)2(acac) HSC transforms the Schottky barrier behavior of the referenced p-Si/Ag interface into that of an Ohmic contact, with a contact resistivity of 97 mΩ cm2. This value is comparable to other HSCs reported to date,24 where the low contact resistivities of the HSCs are commonly attributed to the small valance band offset and the Fermi-level de-pinning effect in the metal–insulator–semiconductor (MIS) structure.25 Finally, we have included the external quantum efficiency (EQE) spectra of the device with and without Ir(piq)2(acac), as shown in Fig. 1e. The device with the Ir(piq)2(acac) HSC is fabricated using the optimal process conditions to be discussed later, showing a slight improvement in the near-infrared spectral range compared to the reference device.

(a) Device schematic of a conventional silicon solar cell incorporating the luminescent small molecule, Ir(piq)2(acac), as the hole-selective contact (HSC). The inset shows the chemical structure of Ir(piq)2(acac) and the luminescence image from the Ir(piq)2(acac) solution under ultraviolet (UV) illumination. (b) Energy band diagram of the silver, silicon, and Ir(piq)2(acac). (c) The backside of a solar cell coated with Ir(piq)2(acac) exhibits a red glow under UV light compared to a reference device without Ir(piq)2(acac). (d) The contact resistivity of the Ir(piq)2(acac)/Ag stacks deposited on a polished p-type c-Si wafer via the transfer length measurement (TLM). (e) The external quantum efficiency (EQE) spectra for solar cells with and without the Ir(piq)2(acac) HSC.

The c-Si solar cells incorporating the Ir(piq)2(acac) HSC exhibit enhanced photovoltaic characteristics compared to their reference counterparts. Table I shows the champion and averaged photovoltaic characteristics, including the short-circuit current density (Jsc), Voc, FF, and PCE for solar cells incorporating the Ir(piq)2(acac) HSC, the reference devices with only toluene treatment, and those without rear surface treatment (baseline). The champion PCEs reach 12.6% for a device with the Ir(piq)2(acac) HSC, compared to 11.6% of the baseline cell. The main improvement arises from the FF, for which the Ir(piq)2(acac) cell boosts the FF from 76.9% (baseline) to 80.5% due to the reduced series resistance from 1.0 Ω cm2 (baseline) to 0.5 Ω cm2. Moreover, the Ir(piq)2(acac) devices also exhibit a slight enhancement on the averaged Voc and Jsc , possibly due to a reduced carrier conduction loss, which can also be seen in the measured EQE in Fig. 1e. In contrast, the devices with only toluene treatment show deteriorated characteristics, which confirms that the performance improvement originates from the Ir(piq)2(acac) layer, instead of the interface modification with toluene. We further monitor the stability performance of the solar cells with and without the Ir(piq)2(acac) HSC stored in the air ambient by measuring the current density–voltage (J–V) characteristics daily for the first 15 days and then once every 5 days, as shown in Fig. 2. The device with the Ir(piq)2(acac) HSC exhibits excellent and stable J–V characteristics with less than 3% degradation from their original efficiency value for up to 30 days (720 h) in air, which to our knowledge, had not previously been reported for c-Si solar cells with an organic HSC.

Stability of the photovoltaic characteristics for solar cells with the Ir(piq)2(acac) hole-selective contact. The reference counterpart is a device without rear surface treatment. The device with the Ir(piq)2(acac) HSC exhibits excellent and stable photovoltaic characteristics with less than 3% degradation from their original efficiency value for up to 30 days (720 h) in air.

We next investigated the device performance versus the process conditions, including the blade velocity and the hot plate annealing temperature. The speed of blade motion was varied between 100 mm/s and 500 mm/s with a fixed acceleration setting of 200 mm/s2, which yields an Ir(piq)2(acac) film thickness ranging from 4.5 ± 0.7 nm to 8.7 ± 2.0 nm (Fig. 3a). According to our previous study, the thickness of organic thin films generally increases with the blade-coating speed. However, a homogeneous coating result requires co-optimization between the blade motion’s velocity and acceleration to achieve adequate film uniformity.26 Therefore, the trend in Fig. 3a agrees well with our previous observations, except for the 100 mm/s coating speed, suggesting that the acceleration setting still requires adjustment at the low coating speed. Nevertheless, the variation in film thickness due to different coating conditions appears to have little impact on the device characteristics, indicating that the Ir(piq)2(acac) HSC is relatively robust and tolerant of the coating conditions (Fig. 3b). Moreover, by confirming the Ir(piq)2(acac) film thickness, we show that the carrier transport is less likely due to tunneling, but rather dominated by thermionic emission. The film thickness has little effect on the device characteristics, further supporting thermionic emission as the main carrier transport mechanism.

In contrast, the annealing temperature plays a critical role in the photovoltaic characteristics, particularly FF and Voc. By fixing the coating speed at 500 mm/s and varying the hot plate annealing conditions from 90°C to 210°C for 10 min, we found that the FF and Voc reach maximum values of 80.5% and 552.2 mV, respectively at 150°C, then 210°C and 180°C, while Jsc remains the same (Fig. 4a). The dark current J–V characteristics also display variations due to the annealing temperature (Fig. 4b). The slight improvement in Voc indicates a minor passivation effect of the Ir(piq)2(acac) HSC, which is also indicated by the reduced saturation current density, as seen in Fig. 4b. Moreover, in the forward bias regime, the dark J–V curves exhibit a relatively sharp slope for the three annealing conditions of 150°C, 210°C, and 180°C compared to others, reducing the ideality factor to ~ 2.5. The lowered ideality factor in the generation–recombination current-dominant region implies mitigated material and interface defects of a p–n diode, which supports the excellent performance for the device annealed at 150°C.

Next, to better understand the origin of the improved FF with the annealing temperature, we investigated the surface work function of the Ir(piq)2(acac) HSCs using an SKPM method. The SKPM provides the two-dimensional distributions of local electrical potential and band bending via measuring the CPD between the probe and the sample, as well as the sample’s topography with a nanometer-scale resolution. Figure 5 shows the measured surface topography and corresponding CPD distributions for the Ir(piq)2(acac)/c-Si samples annealed at (a) 90°C, (b) 120°C, (c) 150°C, (d) 180°C, and (e) 210°C, as well as (f) a reference p-type c-Si wafer without annealing. We can see that the CPD distributions are related to the surface topographies, as the film thickness variation on a substrate can affect the applied DC bias and thus the surface work function. Therefore, in order to obtain reasonable surface work function values, we performed a root-mean-square average of the CPD values over a 1 µm × 1 µm area with a surface roughness value of less than 20 nm from the SKPM measurement. The extracted surface work functions versus the annealing temperature are plotted in Fig. 6a. The Ir(piq)2(acac)/c-Si sample annealed at 150°C has the smallest surface work function of 5.03 eV among the five annealing conditions, while the reference c-Si wafer has one of 4.89 eV. Furthermore, by analyzing the FF shown in Fig. 4a, we find that the series resistance of solar cells containing the Ir(piq)2(acac) HSC shows a similar trend to the annealing temperature as does the surface work function of Ir(piq)2(acac) on c-Si. As illustrated in Fig. 6b, the large surface work function of the Ir(piq)2(acac) layer compared to the p-type c-Si surface indicates an upward energy band bending, which assists hole transport towards the organic silicon interface. However, there still exists a potential barrier between the Ir(piq)2(acac) layer and the silver electrode. Despite the measured film thickness of Ir(piq)2(acac) being about 4–10 nm (Fig. 3a), the holes accumulated at the organic silicon interface can still be conducted in the form of a thermionic emission. Therefore, the relatively small surface work function of the Ir(piq)2(acac) HSC annealed at 150°C gives rise to a lowered barrier height to the electrode, thus increasing the probability of thermionic emission for holes. Therefore, based on the results shown in Fig. 6a, we believe that the enhanced FF and Voc originate from the lowered interfacial barrier and upward band bending at the organic silicon interface, both of which facilitate the hole conduction and collection. While the decrease of effective work function has previously been studied for ESCs employing organic dipole layers,27 our results also show that annealing the Ir(piq)2(acac) HSC could offer the means to engineer the interface band bending in facilitating hole transport.

The measured surface topography (upper figure) and contact potential difference (CPD) (lower figure) distributions via surface Kevin probe microscopy for Ir(piq)2(acac)/c-Si samples annealed at (a) 90°C, (b) 120°C, (c) 150°C, (d) 180°C, and (e) 210°C, and (f) the reference p-type c-Si wafer without annealing.

(a) The series resistance of solar cells containing an Ir(piq)2(acac) HSC demonstrate a similar correlation to the annealing temperature as the surface work function (WF) of Ir(piq)2(acac). (b) A schematic of the energy band bending at the organic–silicon interface with a lowered barrier height to the silver electrode through hot plate annealing at 150°C.

Finally, we incorporated the Ir(piq)2(acac) HSC into an industrial c-Si solar cell using optimized blade coating and annealing conditions. The cell incorporating the Ir(piq)2(acac) HSC utilizes the standardized fabrication processes for the front surface, including vacuum deposition of a 70-nm-thick SiNx layer for passivation and antireflective coating, followed by screen-printed silver electrodes with a 6% metallic shading ratio, as shown in the inset of Fig. 7. Afterward, the rear surface process applies the blade coating of the Ir(piq)2(acac) HSC with a coating speed of 500 mm/s and acceleration setting of 200 mm/s2, followed by hot plate annealing at 150°C for 10 min and the thermal evaporation of a 100-nm-thick silver electrode that fully covers the rear surface. Due to front surface passivation and antireflection, the PCE of the industrial cell incorporating the Ir(piq)2(acac) HSC reaches 17.8%, compared to 16.9% for the reference counterpart without an HSC. The PCE improvement manifests in boosted the FF from 76.8% (ref.) to 78.9%, Voc from 584.9 mV (ref.) to 596.8 mV, and Jsc from 37.4 mA/cm2 (ref.) to 37.8 mA/cm2. The measured photovoltaic characteristics are also close to those in a recent report using a molybdenum oxide (MoOx) HSC.28 We further evaluated the efficiency potential of the Ir(piq)2(acac) HSCs by calculating the figure of merit for carrier selectivity, known as S10.29 By definition, carrier selectivity is the ratio of the minority carrier resistance to the majority carrier resistance. In the case of hole-selective contacts, S10 is defined and as expressed in Eq. 1:

where ρn and ρp denote electron and hole resistance, respectively, Vth is the thermal voltage at 298.15 K, J0 is the minority carrier recombination current density, and ρc is the contact resistance. Through the TLM and minority carrier lifetime measurements, we obtain a ρc of 97 mΩ cm2 and J0 of 8 × 10−13A/cm2, respectively. As a result, S10 is calculated to be 11.51, giving rise to a theoretical PCE of ~ 23% for an ideal solar cell with the Ir(piq)2(acac) HSC. The theoretical efficiency calculation is based on the equivalent circuit model of a hypothetical solar cell composed of an ideal current source with Jsc = 43.6 mA/cm2 from the AM1.5G solar spectrum and a single carrier selective contact characterized by the recombination parameter J0 and contact resistance ρc.29 Since surface passivation is a theoretical efficiency bottleneck for organic HSCs, an energy-efficient passivation method that can be paired with Ir(piq)2(acac) is desired to advance the development of high-efficiency low-cost silicon photovoltaics.30

Conclusions

We have demonstrated a stable organic hole-selective contact based on the luminescent small molecule, Ir(piq)2(acac), for silicon photovoltaics. The solar cell incorporating Ir(piq)2(acac) exhibits a high fill factor and excellent device stability of up to 30 days in air. Based on the SKPM results, we conclude that the enhanced charge transport characteristics originate from an upward energy band bending and a lowered interfacial barrier height to facilitate hole transport and collection across the organic silicon interface. Moreover, the blade-coating process developed for the Ir(piq)2(acac) HSC further capitalizes on scalability, low energy consumption, and minimal material usage. These developments suggest that luminescent small molecules such as Ir(piq)2(acac) can be a promising candidate for organic hole-selective contacts to achieve high-efficiency and low-cost silicon photovoltaics.

References

International Technology Roadmap for Photovoltaic (ITRPV)—Vdma.Org—VDMA, https://www.vdma.org/international-technology-roadmap-photovoltaic

U. Würfel, A. Cuevas, and P. Würfel, Charge carrier separation in solar cells. IEEE J. Photovolt. 5, 461 (2015).

S.W. Glunz, M. Bivour, C. Messmer, F. Feldmann, R. Müller, C. Reichel, A. Richter, F. Schindler, J. Benick, and M. Hermle, in 2017 IEEE 44th Photovoltaic Specialist Conference (PVSC) (2017), p. 206

J. Melskens, B.W.H. van de Loo, B. Macco, L.E. Black, S. Smit, and W.M.M. Kessels, Passivating contacts for crystalline silicon solar cells: from concepts and materials to prospects. IEEE J. Photovolt. 8, 373 (2018).

K. Yoshikawa, H. Kawasaki, W. Yoshida, T. Irie, K. Konishi, K. Nakano, T. Uto, D. Adachi, M. Kanematsu, H. Uzu, and K. Yamamoto, Silicon heterojunction solar cell with interdigitated back contacts for a photoconversion efficiency over 2%. Nat. Energy 2, 17032 (2017).

S. Glunz, F. Feldmann, A. Richter, M. Bivour, C. Reichel, H. Steinkemper, J. Benick, and M. Hermle, in 31st European Photovoltaic Solar Energy Conference and Exhibition, vol. 1 (2015), p. 259

C. Hollemann, F. Haase, S. Schäfer, J. Krügener, R. Brendel, and R. Peibst, 26.%-efficient POLO-IBC cells: quantification of electrical and optical loss mechanisms. Prog. Photovolt. Res. Appl. 27, 950 (2019).

Z.C. Holman, A. Descoeudres, L. Barraud, F.Z. Fernandez, J.P. Seif, S. De Wolf, and C. Ballif, Current losses at the front of silicon heterojunction solar cells. IEEE J. Photovolt. 2, 7 (2012).

S. De Wolf and M. Kondo, Boron-doped a-Si:H/c-Si interface passivation: degradation mechanism. Appl. Phys. Lett. 91, 112109 (2007).

T.G. Allen, J. Bullock, X. Yang, A. Javey, and S. De Wolf, Passivating contacts for crystalline silicon solar cells. IEEE J. Photovolt. 4, 914 (2019).

L.G. Gerling, S. Mahato, A. Morales-Vilches, G. Masmitja, P. Ortega, C. Voz, R. Alcubilla, and J. Puigdollers, Transition metal oxides as hole-selective contacts in silicon heterojunctions solar cells. Sol. Energy Mater Sol. Cells 145, 109 (2016).

C. Lu, R. Rusli, A.B. Prakoso, and H. Wang, Carrier selective solution processed molybdenum oxide silicon heterojunctions solar cells with over 1% efficiency. Semicond. Sci. Technol. 35, 075022 (2020).

Z. Yang, P. Gao, J. He, W. Chen, W.-Y. Yin, Y. Zeng, W. Guo, J. Ye, and Y. Cui, Tuning of the contact properties for high-efficiency Si/PEDOT:PSS heterojunction solar cells. ACS Energy Lett. 2, 556 (2017).

J. Liu, Y. Ji, Y. Liu, Z. Xia, Y. Han, Y. Li, and B. Sun, Doping-free asymmetrical silicon heterocontact achieved by integrating conjugated molecules for high efficient solar cell. Adv. Energy Mater. 7, 1700311 (2017).

C. Reichel, U. Würfel, K. Winkler, H.-F. Schleiermacher, M. Kohlstädt, M. Unmüssig, C.A. Messmer, M. Hermle, and S.W. Glunz, Electron-selective contacts via ultra-thin organic interface dipoles for silicon organic heterojunction solar cells. J. Appl. Phys. 123, 024505 (2018).

W. Ji, T. Allen, X. Yang, G. Zeng, S. De Wolf, and A. Javey, Polymeric electron-selective contact for crystalline silicon solar cells with an efficiency exceeding 1%. ACS Energy Lett. 5, 897 (2020).

Z.R. Li, Organic Light-Emitting Materials and Devices, 2nd ed., (Boca Raton: CRC Press, 2017).

Z. Wang, P. Li, Z. Liu, J. Fan, X. Qian, J. He, S. Peng, D. He, M. Li, and P. Gao, Hole selective materials and device structures of heterojunction solar cells: recent assessment and future trends. APL Mater. 7, 110701 (2019).

P. Gao, Z. Yang, J. He, J. Yu, P. Liu, J. Zhu, Z. Ge, and J. Ye, Dopant-free and carrier-selective heterocontacts for silicon solar cells: recent advances and perspectives. Adv. Sci. 5, 1700547 (2018).

J. Bullock, M. Hettick, J. Geissbühler, A.J. Ong, T. Allen, C.M. Sutter-Fella, T. Chen, H. Ota, E.W. Schaler, S.D. Wolf, C. Ballif, A. Cuevas, and A. Javey, Efficient silicon solar cells with dopant-free asymmetric heterocontacts. Nat. Energy 1, 15031 (2016).

C. Adachi, M.A. Baldo, M.E. Thompson, and S.R. Forrest, Nearly 10% internal phosphorescence efficiency in an organic light-emitting device. J. Appl. Phys. 90, 5048 (2001).

P.-T. Tsai, M.-C. Li, Y.-C. Lai, W.-H. Tseng, C.-I. Wu, S.-H. Chen, Y.-C. Lin, Y.-C. Chen, R.-C. Hsiao, S.-F. Horng, P. Yu, and H.-F. Meng, Solution P-doped fluorescent polymers for enhanced charge transport of hybrid organic-silicon nanowire photovoltaics. Org. Electron. 34, 246 (2016).

J.-H. Jou, S. Kumar, A. Agrawal, T.-H. Li, and S. Sahoo, Approaches for fabricating high efficiency organic light emitting diodes. J. Mater. Chem. C 3, 2974 (2015).

J. Bullock, Y. Wan, M. Hettick, J. Geissbühler, A.J. Ong, D. Kiriya, D. Yan, T. Allen, J. Peng, X. Zhan, C.M. Sutter-Fella, S.D. Wolf, C. Ballif, A. Cuevas, and A. Javey, in 2016 IEEE 43rd Photovoltaic Specialists Conference (PVSC) (2016), p. 0210

M. Sajjad, X. Yang, P. Altermatt, N. Singh, U. Schwingenschlögl, and S. De Wolf, Metal-induced gap states in passivating metal/silicon contacts. Appl. Phys. Lett. 114, 071601 (2019).

P.-T. Tsai, K.-C. Yu, C.-J. Chang, S.-F. Horng, and H.-F. Meng, Large-area organic solar cells by accelerated blade coating. Org. Electron. 22, 166 (2015).

U. Würfel, M. Seßler, M. Unmüssig, N. Hofmann, M. List, E. Mankel, T. Mayer, G. Reiter, J.-L. Bubendorff, L. Simon, and M. Kohlstädt, How molecules with dipole moments enhance the selectivity of electrodes in organic solar cells: a combined experimental and theoretical approach. Adv. Energy Mater. 6, 1600594 (2016).

H. Nasser, F. Es, M. Zolfaghari Borra, E. Semiz, G. Kökbudak, E. Orhan, and R. Turan, On the application of hole-selective MoOx as full-area rear contact for industrial scale p-Type c-Si solar cells. Prog. Photovolt. Res. Appl. 29, 281 (2021).

R. Brendel and R. Peibst, Contact selectivity and efficiency in crystalline silicon photovoltaics. IEEE J. Photovolt. 6, 1413 (2016).

W. Ji, Y. Zhao, H.M. Fahad, J. Bullock, T. Allen, D.-H. Lien, S. De Wolf, and A. Javey, Dip coating passivation of crystalline silicon by lewis acids. ACS Nano 13, 3723 (2019).

Acknowledgments

The authors thank I-Chun Wang for his technical assistance and the National Science and Technology Council, Taiwan for financial support under Grant Numbers 109-2221-E-009-004-MY3 and 109-2124-—009-011. L. Y. Li and H. C. Chang thank the financial support from the Bureau of Energy, Ministry of Economic Affairs, Taiwan under Grant Number 111-S0102.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kuo, LJ., Li, LY., Chang, YC. et al. Stable and Efficient Hole Selective Contacts for Silicon Photovoltaics via Solution-Processed Luminescent Small Molecules. J. Electron. Mater. 52, 2708–2717 (2023). https://doi.org/10.1007/s11664-023-10233-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-023-10233-z