Abstract

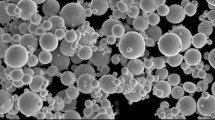

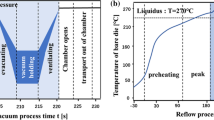

The method of introducing ultrasonic action was used to bond the flip chip with copper pillar solder joints, and the influence of ultrasonic vibration on the structure evolution and mechanical properties of the solder joint was studied. The three-dimensional finite element analysis method was used to simulate the vibration distribution of the chip and the sound pressure distribution in the solder joints. The results indicate that the introduction of ultrasound will cause the intermetallic compound (IMCs) at the upper interface of the solder joint to be broken and thin, and the IMCs at the lower interface will grow and thicken on the original basis. At the same time, the shear strength of the solder joints first increases and then decreases with the increase of the ultrasonic power, and has little relationship with the ultrasonic action time. The introduction of ultrasound in the middle stage of the bonding process will increase the strength of the solder joint, and, in the final stage of the bonding process, will cause larger cracks in the solder joints, which will affect their strength. Simultaneously, the simulation results show that the amplitude at the edge of the upper surface of the chip is larger than that in the middle, and that the sound pressure of the solder joints at the boundary is larger than that of the middle solder joints.

Similar content being viewed by others

References

K.N. Tu, Reliability Challenges in 3D IC Packaging Technology. Microelectron Reliab. 51, 517 (2011).

Y.S. Lai, H.M. Tong, and K.N. Tu, Recent Research Advances in Pb-free Solders. Microelectron Reliab. 49, 221 (2009).

X.J. Fan, A.S. Ranouta, and H.S. Dhiman, Effects of Package Level Structure and Material Properties on Solder Joint Reliability Under Impact Loading. IEEE Trans. Compon. Packaging Manuf. Technol. 3, 52 (2013).

T.K. Lee, K.C. Liu, and T.R. Bieler, Microstructure and Orientation Evolution of the Sn Phase as a Function of Position in Ball Grid Arrays in Sn-Ag-Cu Solder Joints. J. Electron. Mater. 38, 2685 (2009).

S.K. Seo, S.K. Kang, M.G. Cho, D.Y. Shih, and H.M. Lee, The Crystal Orientation of β-Sn Grains in Sn-Ag and Sn-Cu Solders Affected by Their Interfacial Reactions with Cu and Ni(P) Under Bump Metallurgy. J. Electron. Mater. 38, 2461–2469 (2009). https://doi.org/10.1007/s11664-009-0902-4.

A.U. Telang and T.R. Bieler, Characterization of Microstructure and Crystal Orientation of the tin Phase in Single Shear lap Sn-3.5Ag Solder Joint Specimens. Scr. Mater. 52, 1027 (2005).

K.N. Tu, H.Y. Hsiao, and C. Chen, Transition From Flip Chip Solder Joint to 3D IC Microbump: Its Effect on Microstructure Anisotropy. Microelectron Reliab. 53, 2 (2013).

Y.C. Chan, A.C.K. So, and J.K.L. Lai, Growth Kinetic Studies of Cu-Sn Intermetallic Compound and its effect on Shear Strength of LCCC SMT Solder Joints. J. Mater. Sci. Eng. B. 55, 5 (1998).

R. Labie, W. Ruythooren, and J.V. Humbeeck, Solid State Diffusion in Cu-Sn and Ni-Sn Diffusion Couples with Flip-Chip Scale Dimensions. Intermetallics (Barking). 15, 396 (2007).

M.H. Jeong, J.W. Kim, B.H. Kwak et al., Effects of Annealing and Current Stressing on the Intermetallic Compounds Growth Kinetics of Cu/thin Sn/Cu bump. Microelectron Eng. 89, 50 (2012).

B.J. Kim, G.T. Lim, J. Kim, K. Lee, Y.B. Park, H.Y. Lee, and Y.C. Joo, Intermetallic Compound Growth and Reliability of Cu Pillar Bumps Under Current Stressing. J. Electron. Mater. 39, 2281 (2010).

G.T. Lim, B.J. Kim, K. Lee, J. Kim, Y.C. Joo, and Y.B. Park, Temperature Effect on Intermetallic Compound Growth Kinetics of Cu Pillar/Sn Bumps. J. Electron. Mater. 38, 2228 (2009).

C.B. Ke, M.B. Zhou, and X.P. Zhang, Phase field Simulation on Microstructure Evolution and Growth Kinetics of Cu6Sn5 Intermetallic Compound During Early Interfacial Reaction in Sn/Cu Soldering System. Acta Metall. Sin-Engl. 50, 294 (2014).

Y.X. Li, W.W. Zhao, X.S. Leng, Q.J. Fu, L. Wang, and J.C. Yan, Microstructure Evolution and Mechanical Properties of Ultrasonic-Assisted Soldering Joints of 2024 Aluminum Alloys. T Nonferr. Metal. Soc. 21, 1937 (2011).

T. Watanabe, K. Noguchi, A. Yanagisawa, and S. Satoh, Soldering of Aluminum with the Aid of Ultrasonic Vibration (5th Report). The Effect of Ultrasonic Vibration on Soldering Al-Mg Alloy. Quart. J. Japan Weld. Soc. 14, 260–266 (1996). https://doi.org/10.2207/qjjws.14.260.

Z.Q. Zhu, K.Y. Lee, and X.L. Wang, Ultrasonic welding of dissimilar metals, AA6061 and Ti6Al4V. Int. J. Adv. Manuf. Technol. 59, 569 (2012).

R.K. Chinnam, C. Fauteux, J. Neuenschwander, and J. Janczak-Rusch, Evolution of the Microstructure of Sn-Ag-Cu Solder Joints Exposed to Ultrasonic Waves During Solidification. Acta Mater. 59, 1474 (2011).

D.J. Flannigan and K.S. Suslick, Plasma Formation and Temperature Measurement During Single-Bubble Cavitation. Nature 434, 52 (2005).

J.H. Liu, H.Y. Zhao, Z.L. Li, X.G. Song, H.J. Dong, Y.X. Zhao, and J.C. Feng, Study on the Microstructure and Mechanical Properties of Cu-Sn Intermetallic Joints Rapidly Formed by Ultrasonic-Assisted Transient Liquid Phase Soldering. J. Alloys Compd. 692, 552–557 (2017). https://doi.org/10.1016/j.jallcom.2016.08.263.

A.T. Tan, A.W. Tan, and F. Yusof, Evolution of Microstructure and Mechanical Properties of Cu/SAC305/Cu Solder Joints Under the Influence of low Ultrasonic Power. J. Alloys Compd. 705, 188 (2017).

M.L. Castro and F. Priego-Capote, Ultrasound-Assisted Crystallization (sonocrystallization). Ultrason Sonochem. 14, 717 (2007).

T. Nagaoka, Y. Morisada, M. Fukusumi, and T. Takemoto, Joint Strength of Aluminum Ultrasonic Soldered Under Liquidus Temperature of Sn-Zn Hypereutectic Solder. J Mater. Process. Technol. 209, 5054 (2009).

H.J. Ji, Q. Wang, and M.Y. Li, Microstructural Evolution of Lead-Free Solder Joints in Ultrasonic-Assisted Soldering. J. Electron. Mater. 45, 88 (2016).

A. Ramirez, M. Qian, B. Davis, T. Wilks, and D.H. StJohn, Potency of high-Intensity Ultrasonic Treatment for Grain Refinement of Magnesium Alloys. Scr. Mater. 59, 19 (2008).

H.J. Ji, Y.F. Qiao, and M.Y. Li, Rapid Formation of Intermetallic Joints Through Ultrasonic-Assisted die Bonding with Sn-0.7 Cu Solder for high Temperature Packaging Application. Scr. Mater. 110, 19 (2016).

W.Y. Yu, Y.Z. Liu, and Y. Liu, Formation and Evolution of Cu-Sn Intermetallic Compounds in Ultrasonic-Assisted Soldering. J. Electron. Mater. 48, 5595 (2019).

M. Virot, T. Chave, S.I. Nikitenko, D.G. Shchukin, T. Zemb, and H. Mohwald, Acoustic Cavitation at the Water-Glass Interface. J. Phys. Chem. C. 114, 13083 (2010).

J.W. Yoon and S.B. Jung, Solder Joint Reliability Evaluation of Sn-Zn/Au/Ni/Cu Ball-Grid-Array Package During Aging. Mater. Sci. Eng. A. 452, 46 (2007).

M.O. Alam, B.Y. Wu, Y.C. Chan, and L. Rufer, Reliability of BGA Solder-Joints on the Au/Ni/Cu Bond Pad-Effect of Thicknesses of Au and Ni Layer. IEEE Trans. Device Mater. Reliab. 6, 421 (2006).

J.M. Koo, B.Q. Vu, Y.N. Kim, J.B. Lee, J.W. Kim, D.U. Kim, J.H. Moon, and S.B. Jung, Mechanical and Electrical Properties of Cu/Sn-3.5Ag/Cu Ball Grid Array (BGA) Solder Joints after Multiple Reflows. J. Electron. Mater. 37, 118–124 (2008). https://doi.org/10.1007/s11664-007-0301-7.

B.I. Noh, J.M. Koo, J.W. Kim, D.G. Kim, J.D. Nam, J. Joo, and S.B. Jung, Effects of Number of Reflows on the Mechanical and Electrical Properties of BGA Package. Intermetallics (Barking) 14, 1375 (2006).

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. 51975594), National Natural Science Foundation of China’s joint fund for regional innovation and development (No. U20A6004).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, K., Wu, D., Lu, P. et al. Evolution of Microstructure and Mechanical Properties of Copper Pillar Solder Joints Under Ultrasound. J. Electron. Mater. 52, 327–341 (2023). https://doi.org/10.1007/s11664-022-09992-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-022-09992-y