Abstract

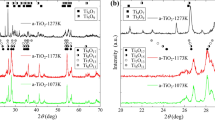

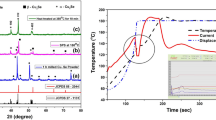

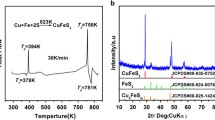

Magnéli phase TinO2n−1 compacts were prepared by in situ reduction of TiO2 with charcoal powder via spark plasma sintering, and their thermoelectric performance was investigated. All the prepared compacts showed a significant decrease in electrical resistivity due to the enhanced carrier concentration originating from the introduced oxygen vacancy defects. The microstructures of the compacts were characterized by scanning electron microscopy, which revealed that grain refinement due to the dry-mixing method promoted the reduction of TiO2 and formed a greater number of oxygen vacancy defects, leading to a further decrease in electrical resistivity of the MA30-5-50 MPa-10 min compact. Moreover, while the absolute Seebeck coefficient decreased as the number of oxygen vacancy defects increased, the power factor was steadily enhanced by a further decrease in the electrical resistivity at elevated temperatures. The x-ray diffraction results suggest that the n index of the Magnéli phase TinO2n−1 mainly depended on the TiO2 reduction and the sintering time, and the formed Magnéli phase Ti6O11 and Ti7O13 contributed significantly to a higher power factor. The highest power factor of 7.31 × 10–4 W m−1 K−2 was achieved in the C30-5-50 MPa-60 min compact at 973 K, and the highest ZT value reached 0.32 at 973 K, indicating an excellent n-type thermoelectric performance.

Similar content being viewed by others

Data Availability

The data used to support the findings of this study are available from the corresponding author upon request.

References

M. Mcalonan, K. Patel, and K. Cummer, AIP Conf. Proc. 813, 573 (2006).

L.E. Bell, Science 321, 1457–1461 (2008).

J. He and T.M. Tritt, Science 357, eaak9997 (2017).

H. Beyer, J. Nurnus, H. Böttner, A. Lambrecht, E. Wagner, and G. Bauer, Physica E 13, 965–968 (2002).

H. Lee, S. Han, R.C. Seshadri, and S. Sampath, Sci. Rep. 6, 36581 (2016).

C. Ou, A.L. Sangle, A. Datta, Q. Jing, T. Busolo, T. Chalklen, V. Narayan, and S. Kar-Narayan, ACS Appl. Mater. Interfaces. 10, 19580–19587 (2018).

H. Frederiksen, J. Appl. Phys. 32, 2211–2215 (1961).

K. Fuda, T. Shoji, S. Kikuchi, Y. Kunihiro, and S. Sugiyama, J. Electron. Mater. 42, 2209–2213 (2013).

C. Liu, L. Miao, J. Zhou, R. Huang, C.A.J. Fisher, and S. Tanemura, J. Phys. Chem. C 117, 11487–11497 (2013).

J. Schilm, A. Ponicke, M. Kluge, I. Sichert, H.P. Martin, and A. Michaelis, Materials Today: Proc 2, 770–779 (2015).

Q. He, Q. Hao, G. Chen, B. Poudel, X. Wang, D. Wang, and Z. Ren, Appl. Phys. Lett. 91, 7009 (2007).

Y. Lan, A. Minnich, G. Chen, and Z. Ren, Adv. Func. Mater. 20, 357–376 (2010).

S. Harada, K. Tanaka, and H. Inui, J. Appl. Phys. 108, 804 (2010).

S. Conze, I. Veremchuk, M. Reibold, B. Matthey, A. Michaelis, Yu. Grin, and I. Kinski, J. Solid State Chem. 229, 235–242 (2015).

L. Hao, Y. Kikuchi, H. Yoshida, Y. Jin, and Y. Lu, J. Alloy. Compd. 722, 846–851 (2017).

S.J. Pandey, G. Joshi, S. Wang, S. Curtarol, and R.M. Gaume, J. Electron. Mater. 45, 5526–5532 (2016).

M. Mikami and K. Ozaki, J. Phys: Conf. Ser. 379, 012006 (2012).

Y. Lu, M. Hirohashi, and K. Sato, Mater. Trans. 47, 1449–1452 (2006).

Y. Lu, L. Hao, H. Sato, S. Guan, H. Yoshida, and H. Asanuma, Mater. Sci. Forum 833, 161–164 (2015).

L. Hao, Z. Wang, Y. Zheng, Q. Li, S. Guan, Q. Zhao, L. Cheng, Y. Lu, and J. Liu, Appl. Surf. Sci. 391, 275–281 (2017).

S. Fukuzaki and A. Kato, Ceramic material process (Japan: Ohmsha Inc., 1987), p. 51.

L. Wang, Z. Li, S. Ohira, T. Itoi, H. Yoshida, and Y. Lu, J. Mater. Sci.: Mater. Electron. 32, 24698–24709 (2021).

D. Palaporn, W. Mongkolthanaruk, S. Tanusilp, K. Kurosaki, and S. Pinitsoontorn, Appl. Phys. Lett. 120, 073901 (2022).

J. Wang, W. Hu, Z. Lou, Z. Xu, X. Yang, T. Wang, and X. Lin, Appl. Phys. Lett. 119, 081901 (2021).

M. Backhaus-Ricoult, J.R. Rustad, D. Vargheese, I. Dutta, and K. Work, J. Electron. Mater. 41, 1636–1647 (2012).

M. Backhaus-Ricoult, J. Rustad, L. Moore, C. Smith, and J. Brown, Appl. Phys.A- Mater. Sci. Process. 116, 433–470 (2014).

D. Portehault, V. Maneeratana, C. Candolfi, N. Oeschler, I. Veremchuk, Y. Grin, C. Sanchez, and M. Antonietti, ACS Nano 5, 9052–9061 (2011).

G. Kieslich and W. Tremel, AIMS Mater. Sci. 1, 184–190 (2014).

Z. Yuan, J. Gong, S. Xu, Z. Li, and G. Tang, J. Alloy. Compd. 710, 778–783 (2017).

Acknowledgments

This work is supported by the Scientific Research Foundation of the Japan Society for the Promotion of Science (JSPS, No. JP19K05053), the China Scholarship Council and the research project of Chengdu Technological University.

Author information

Authors and Affiliations

Contributions

LW: Writing- Original draft preparation, Writing- Reviewing and Editing, Conceptualization, Data curation, and experiment guidance. ZL: Data curation, analysis of the prepared compacts, and XRD characterization. LH: Conceptualization, Data curation, and experiment guidance. SO: Fabrication of the Magnéli phase TinO2n−1 compacts. TI: Methodology, and SEM characterization. HY: Characterization of the prepared compacts, Measurements of thermoelectric performance. YL: Writing- Reviewing, Conceptualization, and Methodology.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interests.

Competing Interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, L., Li, Z., Hao, L. et al. Thermoelectric Performance Enhancement of Magnéli Phase TinO2n−1 Compacts by In Situ Reduction of TiO2 with Charcoal Powder via Spark Plasma Sintering. J. Electron. Mater. 51, 7078–7084 (2022). https://doi.org/10.1007/s11664-022-09942-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-022-09942-8