Abstract

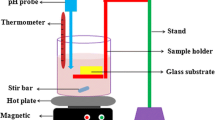

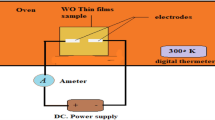

The present study reports on the synthesis of Fe-doped tungsten trioxide (WO3:Fe) thin films using spray-pyrolysis technique. The films were deposited on glass substrates at 350°C and Fe-doping was achieved using granular iron in an acidic medium with \(\frac{{\left[ {{\text{Fe}}} \right]}}{\left[ W \right]}\) = 1, 3 and 5 % at. The films were heat-treated with an extended thermal treatment at 400°C and 500°C for 4 h, in order to allow both crystallization and dopant diffusion into the WO3 matrix. The effect of Fe-doping and heat-treatment on the morphological, structural and optical properties of these films was investigated. The results revealed that Fe-doping has a significant impact on the morphology of the films depending on its concentration. In addition, it was shown that the thermal treatment improves the growth of the crystallites and enhances the roughness of the surface. Grazing incidence X-ray diffraction analysis (GIXRD) confirmed the polycrystalline character of the films with a monoclinic structure (ICDD N° 89-4476, P21/c). The structural parameters were found to be both doping- and heat-treatment-dependent. Energy dispersive spectrometry (EDS) depicted homogeneous doping and confirmed the presence of W, O and Fe. The films display a good optical transmittance over the visible region sensitive to Fe-doping and thermal treatment. Moreover, the films exhibit both direct and indirect electronic transitions, where the energy of the indirect electronic allowed transition shows a redshift in all the samples due to Fe-doping. Therefore, the width of the tail states energy increases inferring the influence of disorder and the introduction of defect states within the band gap region.

Similar content being viewed by others

References

P.S. Kolhe, P. Mutadak, N. Maiti, and K.M. Sonawane, Sens. Actuators A 304, 111877 (2020).

D. Komaraiah, E. Radha, J. Sivakumar, M.R. Reddy, and R. Sayanna, Opt. Mater. 108, 110401 (2020).

S.K. Muhammad, E.S. Hassan, K.Y. Qader, K.H. Abass, S.S. Chiad, and N.F. Habubi, Nano Biomed. Eng 12, 67 (2020).

A.M. Mostafa, and E.A. Mwafy, J. Mol. Struct. 1221, 128872 (2020).

Q. Wang, H. Fu, J. Ding, C. Yang, and S. Wang, Opt. Laser Technol. 125, 106036 (2020).

A.K. Mohamedkhair, Q.A. Drmosh, M. Qamar, and Z.H. Yamani, Catalysts 11, 381 (2021).

Y. Kimura, K. Ibano, K. Uehata, I. Hirai, H.T. Lee, and Y. Ueda, Appl. Surf. Sci. 532, 147274 (2020).

S. Hajirnis, P. Chavan, V. Manapure, A. Patil, A. Khan, B.S. Nadekar, P.S. More, and A.V. Kadam, Mater. Res. Express 8, 095503 (2021).

F.J. García-García, J. Mosa, A.R. Gonzalez-Elipe, and M. Aparicio, Electrochim. Acta 321, 134669 (2019).

Y. Zhao, X. Zhang, X. Chen, W. Li, L. Wang, F. Ren, J. Zhao, F. Endres, Y. Li, and A.C.S. Sustain, Chem. Eng. 8, 11658 (2020).

A. Abareshi, and H. Haratizadeh, Iran. J. Phys. Res. 16, 47 (2019).

D. Nunes, A.R. Fragoso, T. Freire, M. Matias, A.C. Marques, R.F.D.P. Martins, E. Fortunato, and A. Pimentel, Phys. Status Solidi - Rapid Res. Lett. 15, 2100196 (2021).

Y.C. Liang, and C.W. Chang, Coatings 9, 90 (2019).

M. Feng, Y. Liu, Z. Zhao, H. Huang, and Z. Peng, Mater. Res. Bull. 109, 168 (2019).

J. Juodkazytė, M. Petrulevičienė, M. Parvin, B. Šebeka, I. Savickaja, V. Pakštas, A. Naujokaitis, J. Virkutis, and A. Gegeckas, J. Electroanal. Chem. 871, 114277 (2020).

X. San, Y. Lu, G. Wang, D. Meng, X. Gong, and Q. Jin, Mater. Lett. 271, 127716 (2020).

A. Rydosz, K. Dyndał, K. Kollbek, W. Andrysiewicz, M. Sitarz, and K. Marszałek, Vacuum 177, 109378 (2020).

N. Matsunami, M. Sataka, and S. Okayasu, Nucl. Instrum. Methods Phys. Res. B 460, 185 (2019).

L. Pan, Q. Han, Z. Dong, M. Wan, H. Zhu, Y. Li, and Y. Mai, Electrochim. Acta 328, 135107 (2019).

R. Shakoury, A. Arman, S. Rezaee, A.G. Korpi, S. Kulesza, C. Luna, and M. Mardani, J. Mater. Sci. Mater. Electron. 32, 798 (2021).

W. Li, X. Zhang, X. Chen, Y. Zhao, L. Wang, M. Chen, Z. Li, J. Zhao, and Y. Li, Electrochim. Acta 355, 136817 (2020).

Y. Nishijima, K. Enomonoto, S. Okazaki, T. Arakawa, A. Balčytis, and S. Juodkazis, Appl. Surf. Sci. 534, 147568 (2020).

L. S. Parshina, O. A. Novodvorsky, O. D. Khramova, A. A. Lotin and P. A. Shchur, in Journal of Physics: Conference Series 1164, 012003 (2019)

C.M. Chang, Y.C. Chiang, M.H. Cheng, S.H. Lin, W.B. Jian, J.T. Chen, and K. Tsukagoshi, Sol. Energy Mater. Sol. Cells 223, 110960 (2021).

Z. Han, J. Ren, J. Zhou, S. Zhang, Z. Zhang, L. Yang, and C. Yin, Int. J. Hydrog. Energy. 45, 7223 (2020).

X. Li, Z. Li, W. He, H. Chen, X. Tang, Y. Chen, and Y. Chen, Coatings 11, 959 (2021).

G. Mathankumar, P. Bharathi, M.K. Mohan, S. Harish, M. Navaneethan, J. Archana, and C. Muthamizhchelvan, Mater. Sci. Semicond. Process. 105, 104732 (2020).

V. Saasa, T. Malwela, Y. Lemmer, M. Beukes, and B. Mwakikunga, Mater. Sci. Semicond. Process. 117, 105157 (2020).

S. Buathet, K. Simalaotao, P. Reunchan, V. Vailikhit, P. Teesetsopon, D. Raknual, and A. Tubtimtae, Electrochim. Acta 341, 136049 (2020).

M. Arshad, S. Ehtisham-ul-Haque, M. Bilal, N. Ahmad, A. Ahmad, M. Abbas, and M. Iqbal, Mater. Res. Express 7, 015407 (2020).

H. Khan, M. Habib, A. Khan, and D.C. Boffito, J. Environ. Chem. Eng. 8, 104282 (2020).

S.S. Hossain, K. Praveena, and P.K. Roy, J. Mater. Sci. Mater. Electron. 31, 15097 (2020).

M. Kumar Mohanta, T. Kanta Sahu, S. Alam, and M. Qureshi, Chem. Asian J. 15, 3886 (2020).

C. Qiu, Q. Meng, M. Panchal, C. Li, and B. Wu, Catal. Commun 147, 106149 (2020).

M. Farooqi, M. Hasan, R. K. Srivastava, in Proc. Natl. Acad. Sci. India - Phys. Sci. 90 (2020), pp. 845–859

Z. Li, X. Liu, M. Zhou, S. Zhang, S. Cao, G. Lei, C. Lou, and J. Zhang, J. Hazard. Mater. 415, 125757 (2021).

N. Bashirom, and Q.L. Lee, Mater. Sci. Forum 1010, 405 (2020).

D. Dong, J. Robichaud, and Y. Djaoued, Can. J. Chem. 99, 549 (2021).

Y.S. Haiduk, A.A. Khort, M.A. Makhavikou, and A.A. Savitsky, Mod. Electron. Mater. 5, 115 (2019).

S. M. Abd Al Hussan, N. A. Bakr, A. N. Abd, in IOP Conference Series: Materials Science and Engineering, vol. 928 (2020), pp. 072142

S. Sivakumar, E. Manikandan, and B. Mahalakshmi, Vacuum 173, 109116 (2020).

A.A. Akl, I.M. El Radaf, and A.S. Hassanien, Optik 227, 165837 (2021).

V. Luxmi, and A. Kumar, Mater. Sci. Semicond. Process. 104, 104690 (2019).

E.M. Ngigi, P.N. Nomngongo, and J.C. Ngila, Catal. Lett. 149, 49 (2019).

C.T. Nguyen, T.P. Pham, T.L.A. Luu, X.S. Nguyen, T.T. Nguyen, H.L. Nguyen, and D.C. Nguyen, Ceram. Int. 46, 8711 (2020).

M.M. Thwala, and L.N. Dlamini, Environ. Technol. 41, 2277 (2020).

S.S. Shendage, V.L. Patil, S.A. Vanalakar, S.P. Patil, J.L. Bhosale, J.H. Kim, P.S. Patil, and Z. Phys, Chem. 234, 1819 (2020).

I.A. Rodionov, A.S. Baburin, A.R. Gabidullin, S.S. Maklakov, S. Peters, I.A. Ryzhikov, and A.V. Andriyash, Sci. Rep. 9, 1 (2019).

L. Xu, G. Zheng, F. Xian, and J. Su, Mater. Chem. Phys. 229, 215 (2019).

A. Haichour, and N. Hamdadou, J. Nano- Electron. Phys. 11, 06020 (2019).

L.K. Sharma, M. Kar, R.K. Choubey, and S. Mukherjee, Chem. Phys. Lett. 780, 138902 (2021).

G. Soman, A. Shajan, J. Jassi, N. K. Vijay, in AIP Conference Proceedings, vol. 2263 (2020), p. 050006.

P.K. Pothuganti, A. Bhogi, M.R. Kalimi, and P. Reniguntla, Glass Phys. Chem. 46, 146–154 (2020).

A. Ammari, and M. Trari, Colloids Surf. A 61, 178–186 (2019).

J. Liu, G. Zhang, K. Guo, D. Guo, M. Shi, H. Ning, T. Qiu, J. Chen, X. Fu, R. Yao, and J. Peng, Micromachines 11, 311 (2020).

R.I. Eglitis, J. Purans, and R. Jia, Curr. Comput.-Aided Drug Des. 11, 455 (2021).

D. Acosta, F. Hernández, A. López-Suárez, and C. Magaña, Solid State Phenom. 286, 49–63 (2019).

S. Kumari, K. Singh, P. Singh, S. Kumar, and A. Thakur, SN Appl. Sci. 2, 1 (2020).

T. Hamai, S. Inoue, S. Arai, and T. Hasegawa, Phys. Rev. Mater. 4, 074601 (2020).

A. Ammari, M. Trari, and N. Zebbar, Mater. Sci. Semicond. Process. 89, 97–104 (2019).

Acknowledgments

The authors which to thank Professor Bouslama M’Hammed, the Director of the Materials Laboratory (ENPO-Oran), for providing access to AFM measurements, and Dr. Mhamed Guezzoul from the same laboratory for his help in these measurements.

Funding

This work was funded by the Directorate-General for Scientific Research and Technological Development, Ministry of Higher Education and Scientific Research (Algeria).

Author information

Authors and Affiliations

Contributions

All authors contributed to this research work equally.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ouadah, E., Hamdadou, NE. & Ammari, A. Morphological, Structural and Optical Properties of Fe-Doped WO3 Films Deposited by Spray-Pyrolysis. J. Electron. Mater. 51, 356–369 (2022). https://doi.org/10.1007/s11664-021-09300-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-021-09300-0