Abstract

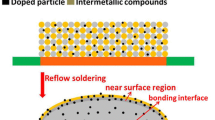

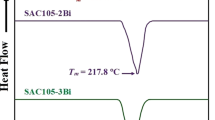

Bismuth (Bi)-containing solder alloys have emerged as prime candidates to replace traditional lead (Pb)-free alloys such as SAC 305 (Sn-3.0Ag-0.5Cu, in wt.%); unlike SAC alloys, these alloys show stability in mechanical properties after aging. A process was developed in which a Bi-bearing alloy is intentionally subjected to a short above-solvus thermal treatment, to potentially extend the life of the solder joint and improve device reliability. This treatment may be implemented after reflow, or periodically in service as a form of preventive maintenance. In this work, we evaluated this treatment as both a preconditioning and restoration process to compare Violet (Sn-2.25Ag-0.5Cu-6.0Bi, in wt.%) and SAC 305 alloys. Firstly, the solvus temperature of Violet was evaluated experimentally; this result was used to determine an appropriate heat treatment temperature for preconditioning and restoration. It was found that the heat treatment produces a highly equiaxed β-Sn grain structure, likely caused by particle stimulated nucleation during Bi precipitation. The creep resistance of the alloy was found to improve after the treatment. Finally, it was observed that both Bi and preconditioning can have varying effects on the thermal cycling reliability of the alloy, depending on the harshness of the thermal cycle (ΔT).

Similar content being viewed by others

References

H. Ma, J. Suhling, Y. Zhang, P. Lall, and M.J. Bozack, in Electronic Components and Technology Conference Proceedings (2007), pp. 653–658

M. Hasnine, M. Mustafa, J.C. Suhling, B.C. Prorok, M.J. Bozack, and P. Lall, in 2013 Electronic Components and Technology Conference Proceedings (2013), pp. 168–178

R. Coyle, J. Smetana, D. Hillman, C. Johnson, R. Parker, B. Sandy-Smith, H. Zhang, J. Geng, M. Osterman, B. Arfaei, A. Delhaise, K. Howell, J. Bath, S. Longgood, A. Kleyner, J. Silk, R. Pandher, E. Lundeen, and J. Noiray, in SMTA International Conference Proceedings (2018)

P.T. Vianco and J.A. Rejent, J. Electron. Mater. 28, 10 (1999).

Z. Moser, W. Gasior, K. Bukat, J. Pstrus, R. Kisiel, J. Sitek, K. Ishida, and I. Ohnuma, J. Phase Equilib. Diffus. 27, 2 (2006).

D. Witkin, in APEX Expo Proceedings (2013), pp. 540–560

J. Juarez, P. Snugovsky, E. Kosiba, Z. Bagheri, S. Subramaniam, M. Robinson, J. Heebink, J. Kennedy, and M. Romansky, J. Microelectron. Electron. Packag. 12, 1 (2015).

N. Jadhav, M. Williams, F. Pei, G. Stafford, and E. Chason, J. Electron. Mater. 42, 2 (2013).

D. Witkin, J. Electron. Mater. 41, 2 (2012).

A. Delhaise, L. Snugovsky, D. Perovic, P. Snugovsky, and E. Kosiba, J. Surf. Mt. Technol. 27, 3 (2014).

A. Delhaise, D. Perovic, and P. Snugovsky, J. Surf. Mt. Technol. 30, 2 (2017).

T.-K. Lee, T. Bieler, C.-U. Kim, and H. Ma, Fundamentals of Lead-Free Interconnect Technology, 1st ed. (New York: Springer, 2015), p. 81.

A. Delhaise, Z. Chen, and D. Perovic, J. Electron. Mater. 47, 3 (2018).

A. Delhaise, Z. Chen, and D. Perovic, JOM 71, 1 (2019).

E. Arzt, Acta Mater. 46, 16 (1998).

B.-J. Lee, C.-S. Oh, and J.-H. Shim, J. Electron. Mater. 25, 6 (1996).

T.-K. Lee, T. Bieler, C.-U. Kim, and H. Ma, Fundamentals of Lead-Free Interconnect Technology, 1st ed. (New York: Springer, 2015), p. 93.

F.J. Humphreys and M. Hatherly, Recrystallization and Related Annealing Phenomena, 2nd ed. (Oxford: Elsevier, 2004), pp. 293–303.

J. Dean, A. Bradbury, G. Aldrich-Smith, and T.W. Clyne, Mech. Mater. 65, 1 (2013). https://doi.org/10.1016/j.mechmat.2013.05.014.

P. Vianco, J. Rejent, M. Grazier, and A. Kilgo, Materials 5, 11 (2012).

M.E. Kassner, Fundamentals of Creep in Metals and Alloys, 3rd ed. (Waltham: Butterworth-Heinemann, 2015), p. 91.

R.D. Doherty, D.A. Hughes, F.J. Humphreys, J.J. Jonas, D. Juul Jensen, M.E. Kassner, W.E. King, T.R. McNelley, H.J. McQueen, and A.D. Rollett, Mater. Sci. Eng. A 238, 2 (1997).

R.B. Abernathy, The New Weibull Handbook, 2nd ed. (North Palm Beach: Robert B. Abernathy, 1996), p. 31.

L. Yin, L. Wentlent, L. Yang, B. Arfaei, A. Oasaimeh, and P. Borgesen, J. Electron. Mater. 41, 2 (2012).

P. Boregsen, L. Wentlent, S. Hamasha, S. Khasawneh, S. Shirazi, D. Schmitz, T. Alghoul, C. Greene, and L. Yin, J. Electron. Mater. 47, 5 (2018).

J. Hokka, T. Mattila, H. Xu, and M. Paulasto-Kröckel, J. Electron. Mater. 42, 6 (2013).

F.J. Humphreys and M. Hatherly, Recrystallization and Related Annealing Phenomena, 2nd ed. (Oxford: Elsevier, 2004), p. 18.

T.T. Mattila and J.K. Kivilahti, Recrystallization, ed. K. Sztwiertnia (London: IntechOpen, 2012), p. 189.

Q. Shao, L. Liu, T. Fan, D. Yuan, and J. Chen, J. Alloys Compd. (2017). https://doi.org/10.1016/j.jallcom.2017.07.332.

M. Bhatia, I. Adlakha, G. Lu, and K. Solanki, Scr. Mater. (2016). https://doi.org/10.1016/j.scriptamat.2016.05.038.

P. Banh, A. Delhaise, and D. Perovic, J. Surf. Mt. Technol. 32, 2 (2019).

S. Belyakov, J. Xian, G. Zeng, K. Sweatman, T. Nishimura, T. Akaiwa, and C. Gourlay, J. Mater. Sci. Electron. 30, 1 (2019).

A. Delhaise, P. Snugovsky, I. Matijevic, J. Kennedy, M. Romansky, D. Hillman, D. Adams, S. Meschter, J. Juarez, M. Kammer, I. Straznicky, L. Snugovsky, and D. Perovic, J. Surf. Mt. Technol. 31, 1 (2018).

A. Delhaise, D. Hillman, P. Snugovsky, J. Kennedy, R. Wilcoxon, D. Adams, S. Meschter, J. Juarez, M. Kammer, I. Straznicky, and D. Perovic, J. Surf. Mt. Technol. 32, 1 (2019).

Acknowledgments

The authors would like to thank Dr. Matthew Daly and Prof. Chandra Veer Singh for assistance with nanoindentation, as well as co-op students at Collins Aerospace for failure analysis of the ATC samples. Financial assistance from the Department of Materials Science and Engineering and the Refined Manufacturing Acceleration Process (ReMAP) are greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Delhaise, A.M., Snugovsky, P., Kennedy, J. et al. Thermal Preconditioning and Restoration of Bismuth-Containing, Lead-Free Solder Alloys. J. Electron. Mater. 49, 116–127 (2020). https://doi.org/10.1007/s11664-019-07666-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-019-07666-w