Abstract

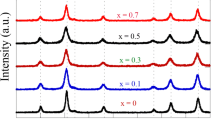

The effects of polyvinyl pyrrolidone (PVP) as a capping agent on the structure, morphology, magnetic hysteresis (M–H) loop, optical and dielectric properties of ZnFe2O4 nanoparticles synthesized by a co-precipitation method were investigated. The precursors used during preparation were FeCl3·6H2O, ZnCl2, and 4 M NaOH with different concentrations of PVP: 0 (pure sample), 0.35 × 10−3 M, 0.69 × 10−3 M, 1.03 × 10−3 M, and 1.38 × 10−3 M. The prepared samples were characterized and investigated using x-ray powder diffraction (XRD), transmission electron microscope (TEM), UV–visible optical spectroscopy, Fourier transform infrared (FTIR), magnetic hysteresis (M–H), and dielectric measurements. XRD patterns reveal a face-centered cubic structure for ZnFe2O4 and confirm that the lattice parameter decreases as the PVP concentration increases. TEM results reveal some aggregation of nanoparticles and a decrease in crystallite size with increasing PVP addition. The energy gap (Eg) increases with an increase of PVP concentration, confirming the decrease of crystallite size as the PVP concentration increases. The FTIR results indicate that PVP addition induces a blue shift with slight variations in the wavelengths of the metal oxide bands. M–H results show that the uncapped PVP sample exhibits ferromagnetic behavior that changes to superparamagnetic with PVP addition up to 1.03 × 10−3 M, along with an increase in the saturation magnetization Ms. The coercivity Hc increases up to a PVP concentration of 0.35 × 10−3 M, and then decreases up to a PVP concentration of 1.03 × 10−3 M. The dielectric constant and dielectric loss measured at room temperature decrease when increasing the frequency, but increase when increasing the temperature or PVP concentration. These results indicate that there is a critical amount of PVP that must be added in order to control the properties of ZnFe2O4 nanoparticles to use them for dielectric and magnetic applications.

Similar content being viewed by others

References

S. Lin, D. Zhang, X. Pan, Y. Du, J. Liu, D. Fan, Y. Wang, K. Bi, and M. Lei, J. Nanosci. Nanotechnol. 17, 2917 (2017).

M.A. Ali, M.M. Uddin, M.N.I. Khan, F.U.Z. Chowdhury, and S.M. Haque, Chin. Phys. B 7, 26 (2017).

S. Manjura Hoque, M. Sazzad Hossain, C. Shamima, S. Akhter, and F. Hyder, J. Mater. Lett. 162, 60–63 (2016).

S. Balci, I. Sefa, and N. Altin, J. Electron. Mater. (2016). https://doi.org/10.1007/s11664-016-4559-5.

Y. Huang, Y. Liang, Y. Rao, D. Zhu, J. Cao, Z. Shen, W. Ho, and S. C. Lee, Environ. Sci. Technol. 51, 2924–2933 (2017).

S.A. Seyyed Ebrahimi and S.M. Masoudpanah, J. Magn. Magn. Mater. 357, 77–81 (2014).

X. Liu, J. Liu, S. Zhang, Z. Nan, and Q. Shi, J. Phys. Chem. C 120, 1328–1341 (2016).

C. Suchomski, B. Breitung, R. Witte, M. Knapp, S. Bauer, T. Baumbach, C. Reitz, T. Brezesinski, and Beilstein, J. Nanotechnol. 7, 1350–1360 (2016).

I. Ibrahim, O. Ali, I.M.T. Salama, A.A. Bahgat, and M. Mohamed, Appl. Catal. B Environ. 181, 389–402 (2016).

Y. Zhang, Y. Wu, Q. Qin, F. Wang, and D. Chen, J. Magn. Magn. Mater. 409, 6–9 (2016).

R. Awad, A.I. Abou Aly, N.H. Mohammed, S. Isber, H.A. Motaweh, and D. El-Said Bakeer, J. Alloys Compd. 610, 614–622 (2014).

C. Wanga, X. Tanb, J. Yana, B. Chaia, J. Lia, and S. Chenc, Appl. Surf. Sci. 396, 780–790 (2017).

A. Marzouk, M. Abu-Dief, and A.A. Abdelhamid, Appl. Organometal. Chem. 32, 3794 (2017).

A.M. Abu-Dief and S.M. Abdel-Fatah, BJBAS (2017). https://doi.org/10.1016/j.bjbas.2017.05.008.

R. Sagayaraj, S. Aravazhi, P. Praveen, and G. Chandrasekaran, J. Mater. Sci. Mater. Electron. 29, 2151–2158 (2017).

K.M. Koczkur, S. Mourdikoudis, L. Polavarapu, and S.E. Skrabalak, Dalton Trans. R. Soc. Chem. (2015). https://doi.org/10.1039/c5dt02964c.

H. Kamari, M. GoodarzNaseri, and E.B. Saion, Metals 4, 118–129 (2014).

M. GoodarzNaseri, E.B. Saion, and N. Zadeh, Int. Nano Let. (2013). https://doi.org/10.1186/2228-5326-3-19.

Z. Bitar, D. El-Said Bakeer, and R. Awad, IOP Conf. Ser. J. Phys. Conf. Ser. 869, 012045 (2017).

A. Manikandan, L. JohnKennedy, M. Bououdina, and J. JudithVijaya, Superlattices Microst. (2014). https://doi.org/10.1016/j.spmi.2013.09.021.

Zulfiqar, S. Afzal, R. Khan, T. Zeb, M. Rahman, A. Burhanullah, S. Ali, G. Khan, Z. Rahmana, and Hussain, J. Mater. Sci. Mater. Electron. (2018). https://doi.org/10.1007/s10854-018-0134-6.

K. Zhou, W. Chen, X. Wu, W. Wu, C. Lin, and J. Wu, J. Electron. Mater. 46, 4618 (2017).

I. Ahmad, S.M. Shah, M.N. Ashiq, F. Nawaz, A. Shah, M. Siddiq, I. Fahim, and S. Khan, J. Electron. Mater. 45, 4979 (2016).

A. Saini, A. Thakur, and P. Thaku, J. Electron. Mater. (2016). https://doi.org/10.1007/s11664-016-4634-y.

I. Bodale, M. Oprisan, C. Stan, F. Tufescu, M. Racuciu, D. Creanga, and M. Balasoiu, in IFMBE Proceedings (2016), pp. 153–156.

A. Syafiuddin, S. Salmiati, T. Hadibarata, A. Beng Hong Kueh, M. Razman Salim, and M. Abbas Ahmad Zaini, Sci. Rep. (2018). https://doi.org/10.1038/s41598-018-19375-1.

M.D. Johan Ooi and M.M. Hassin, MAS 3, 2 (2009).

R. Hassan, J. Hassan, M. Hashim, S. Paiman, and R. Azis, J. Adv. Ceram. (2014). https://doi.org/10.1007/s40145-014-0122-0.

H.A. Ahmad, N.M. Saiden, E. Saion, R.S. Azis, M.S. Mamat, and M. Hashim, J. Magn. Magn. Mater. (2017). https://doi.org/10.1016/j.jmmm.2016.12.047.

J. Li, K. Inukai, Y. Takahashi, A. Tsuruta, and W. Shin, J. Asian Ceram. Soc. 5, 216–225 (2017).

J. Hwang, Y. Shim, S. Yoon, S. Hyun Lee, and S. Park, R. Soc. Chem. (2016). https://doi.org/10.1039/c5ra28003f.

M. Mozaffari and H. Masoudi, J. Supercond. Nov. Magn. 27, 2563–2567 (2014).

M. Suzuki, K. Nakata, R. Kuroda, T. Kobayashi, and E. Tokunaga, Chem. Phys. 469–470, 88–96 (2016).

T.M. Hammad, J.K. Salem, A. Abu Amsha, and N.K. Hejazy, J. Alloys Compd. (2018). https://doi.org/10.1016/j.jallcom.2018.01.123.

A.G. Hufnagel, K. Peters, A. Müller, C. Scheu, D. Fattakhova-Rohlfing, and T. Bein, Adv. Funct. Mater. 26, 4435–4443 (2016).

M.F. Valan, A. Manikandan, and S. Arul Antony, J. Nanosci. Nanotechnol. (2015). https://doi.org/10.1166/jnn.2015.9801.

P. Sun Yoo, D.A. Reddy, Y. Jia, S. Bae, S. Huh, C. Liu, and J. Colloid, Interface Sci. (2017). https://doi.org/10.1016/j.jcis.2016.09.066.

P. Vinosha, L. Ansel Mely, J. EmimaJeronsia, S. Krishnan, and S. Jerome Das, Optik 134, 99–108 (2017).

A. Singh, A. Singh, S. Singh, P. Tandon, B.C. Yadav, and R.R. Yadav, J. Alloys Compd. 618, 475–483 (2015).

M. Shahmiri, N. Ibrahima, F. Shayesteh, N. Asim, and N. Motallebi, J. Mater. Res. (2013). https://doi.org/10.1557/jmr.2013.316.

A. Awadallaha, S.H. Mahmood, Y. Maswadeh, I. Bsoul, M. Awawdeh, Q.I. Mohaidat, and H. Juwhari, Mater. Res. Bull. 74, 192–201 (2016).

D. Maiti, A. Saha, and P. Sujatha Devi, J. Phys. Chem. Chem. Phys. 18, 1439–1450 (2016).

R.B. Jotania, R.A. Nandotaria, C.C. Chauhan, M. Hashim, S.S. Meena, and S.E. Shirsath, Ceram. Int. 42, 2289–2298 (2016).

M. Zargar Shoushtari, A. Emami, and S. Mosavi Ghahfarokhi, Mater. Res. Express 5, 075024 (2018).

M. Zargar Shoushtari, A. Emami, and S. Mosavi Ghahfarokhi, Mater. Res. Express 419, 572–579 (2016).

B. Hangai, E. Borsari, E.C. Aguiar, F.G. Garcia, E. Longo, and A.Z. Simoes, J. Mater. Sci. Mater. Electron. 28, 10772–10779 (2017).

M. Obaidat, B. Issa, and Y. Haik, Nanomaterials 2079–4991, 63–89 (2015).

M. Vadivel, R. Ramesh Babu, K. Ramamurthi, and M. Arivanandhan, Nano-Struct. Nano-Obj. 11, 112–123 (2017).

P. Veverka, K. Knızek, E. Pollert, J. Bohacek, S. Vasseur, E. Duguet, and J. Portier, J. Magn. Magn. Mater. (2006). https://doi.org/10.1016/j.jmmm.2006.06.019.

H. Hoffmann, Thin Solid Films 58, 223–233 (1979).

S.S. Kumbhar, M.A. Mahadik, S.S. Shinde, K.Y. Rajpure, and C.H. Bhosale, J. Photochem. Photobiol. B Biol. 142, 118–123 (2015).

T. Thu Nga Vu, G. Teyssedre, S. Roy Le, and C. Laurent, Technologies 5, 27 (2017).

R.A. Pawar, S.S. Desai, S.M. Patange, S.S. Jadhav, and K.M. Jadhav, Phys. B Phys. Condens. Matter 510, 74–79 (2017).

K. Mandal, S. Singh, P. Dey, J.N. Roy, P.R. Mandal, and T.K. Nath, J. Alloys Compd. 656, 887–896 (2015).

R. Singh Yadav, I. Kuřitka, J. Vilcakova, J. Havlica, J. Masilko, L. Kalina, J. Tkacz, J. Švec, V. Enev, and M. Hajdúchová, Adv. Nat. Sci. Nanosci. Nanotechnol. (2017). https://doi.org/10.1016/j.jpcs.2017.05.029.

N. Ponpandian and A. Narayanasamy, J. Appl. Phys. 92, 2770 (2002).

K. Ramarao, B. Rajesh Babu, B. Kishore Babu, V. Veeraiah, S.D. Rama Rao, K. Rajasekhar, and A. Venkateswararao, J. Electron. Mater. (2018). https://doi.org/10.1007/s11664-018-6179-8.

T. Khoon, J. Hassan, Z. Abd Wahab, and R. Syahid Ahazis, Eng. Sci. Technol. (2016). https://doi.org/10.1016/j.jestch.2016.08.002.

M.N. Siddique, A. Ahmed, and P. Tripathi, J. Alloys Compd. (2018). https://doi.org/10.1016/j.jallcom.2017.11.114.

Acknowledgments

This work was performed in the materials science lab, Physics Department, Faculty of Science, Beirut Arab University, in collaboration with the Faculty of Science, Alexandria University, Alexandria, Egypt and the Faculty of Science, Lebanese University, Beirut, Lebanon.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Alsayed, Z., Badawi, M.S. & Awad, R. Characterization of Zinc Ferrite Nanoparticles Capped with Different PVP Concentrations. J. Electron. Mater. 48, 4925–4933 (2019). https://doi.org/10.1007/s11664-019-07288-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-019-07288-2